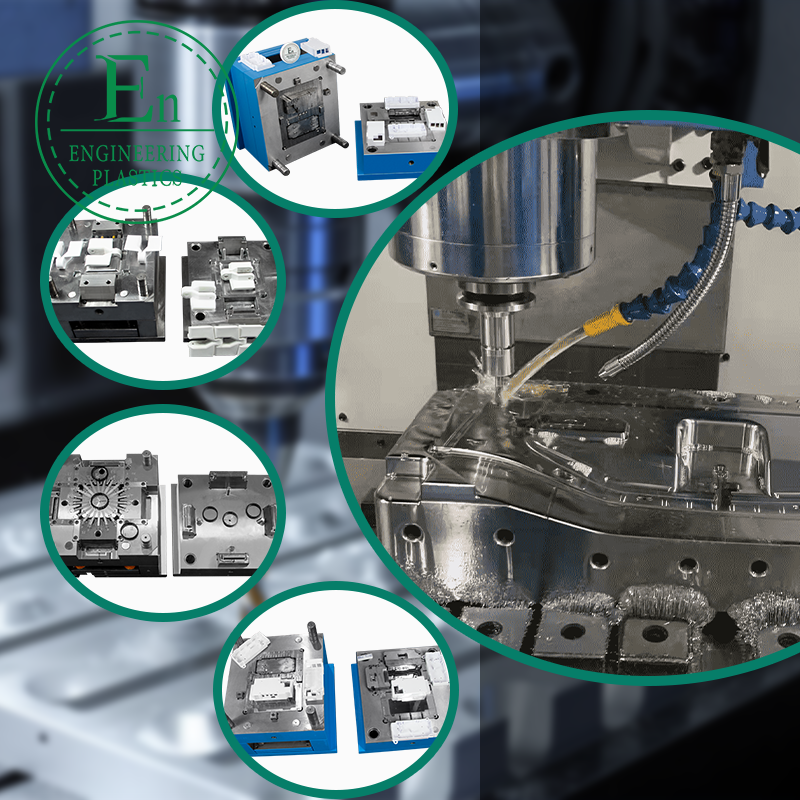

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

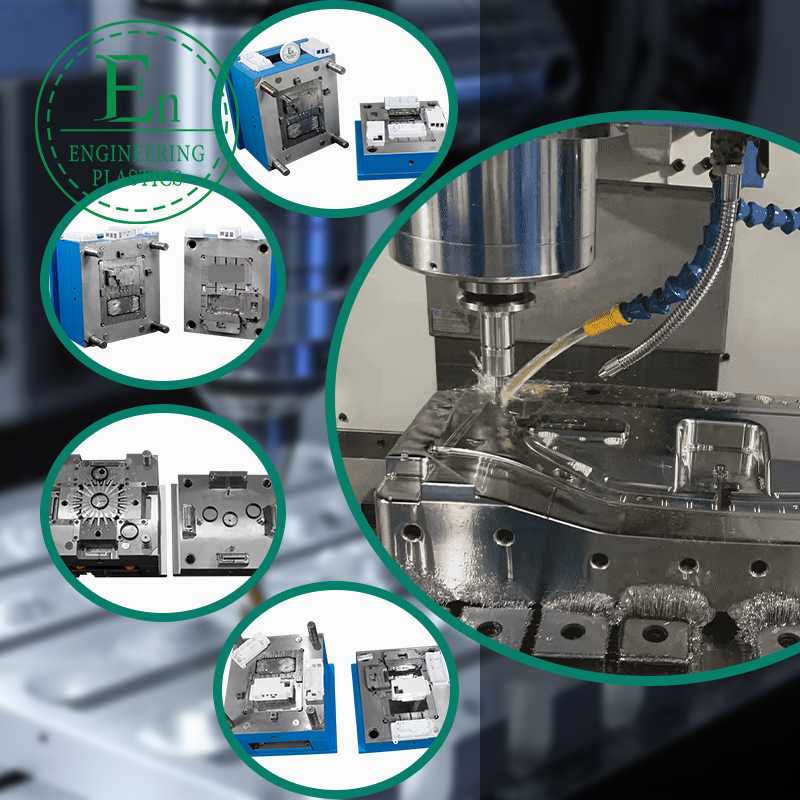

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Injection mold manufacture is the foundation of modern plastic production. From precision medical components to aerospace-grade housings, the performance of each plastic part depends heavily on the quality of the mold that shapes it. A high-quality mold guarantees consistency, durability, tight tolerances, and cost efficiency throughout the full product lifecycle.

In this in-depth guide, we explain how injection molds are manufactured, the technologies involved, what determines mold quality, and how to choose a trustworthy mold-making partner.

What Is Injection Mold Manufacture?

Injection mold manufacture refers to the engineering and production process of building metal tools that form molten plastic into a specific shape.

A well-made mold must deliver:

Dimensional accuracy

Consistent cycle times

Excellent surface finish

Long-term durability

Stable and predictable performance

Industries such as automotive, aerospace, robotics, consumer electronics, and medical devices rely heavily on precision molds.

Why Proper Mold Manufacturing Determines Final Product Quality

A plastic part is only as good as its mold. Even the best injection molding machines cannot compensate for a poorly manufactured mold.

Major benefits of high-quality mold manufacturing

Better product consistency

Faster molding cycles

Lower scrap rates

Reduced maintenance and repair costs

Longer mold life (hundreds of thousands or millions of shots)

This is why choosing the right mold manufacturer is a critical business decision.

Core Stages of Injection Mold Manufacture

1. Engineering & Mold Design

The first step—mold design—dictates over 70% of the mold’s performance.

Key design considerations

Mold flow analysis (to avoid short shots, sink marks, and warpage)

Cooling channel design

Gate and runner optimization

Parting line location

Ejection system layout

Vent control

A well-optimized design reduces production time, improves surface quality, and prevents defects.

2. CNC Machining & EDM Processing

High-precision machining transforms digital models into real steel components.

Equipment typically used

Five-axis CNC milling

High-speed machining centers

EDM (Electrical Discharge Machining)

Wire-cut EDM

Precision grinders

These machines achieve the tight tolerances required for high-precision molds, often within ±0.01 mm.

3. Mold Assembly & Tuning

After machining, the mold components are hand-fitted and assembled by skilled technicians.

Includes:

Hand polishing

Mirror finishing of mold cavities

Texture application

Alignment & fitting

Assembly of hot runner or cold runner systems

This step is key to achieving a glossy surface or detailed texture on final products.

4. Mold Trial Runs (T0–T2 Testing)

Before mass production, the mold undergoes trial injection cycles.

Technicians evaluate:

Filling behavior

Cooling efficiency

Warpage and shrinkage

Gate marks and surface defects

Dimensional tolerance

Adjustments are made until the performance is stable and meets spec.

5. Mass Production Support

A finished mold can run on injection molding machines from 50 to 1500 tons based on part size.

Quality control involves:

Dimensional inspection

Surface integrity checking

Color and material validation

Mechanical testing

Why Choose Guangdong Engineering Plastics Industries Group Co., Ltd. for Injection Mold Manufacture?

With over 28 years of experience, Guangdong Engineering Plastics Industries Group Co., Ltd. is a leading global provider of custom injection molds & molding solutions.

Our Strengths

✔ Advanced Mold Design

Multi-cavity systems

Hot runner technologies

Micro-molding

Complex geometries

✔ Full-Service Production From Prototyping to Mass Production

We offer one-stop service:

Rapid design

Prototyping

High-volume injection molding

Secondary processing & assembly

✔ Material Expertise

We work with:

Engineering plastics

LSR (Liquid Silicone Rubber)

Biodegradable polymers

High-temperature & high-strength materials

✔ ISO 9001 Certified Quality Control

Precision up to ±0.01 mm

Automated inspection systems

Full mold validation before shipment

✔ Industries Served

Aerospace

Automotive

Robotics

Medical devices

Consumer electronics

Our engineering team helps clients reduce cycle time, optimize tooling costs, and increase product performance.

Cost Drivers in Injection Mold Manufacture

The cost of a mold depends on:

Type of steel (P20, H13, S136, NAK80…)

Mold size & complexity

Number of cavities

Runner system (hot runner vs. cold runner)

Surface finishing

Mold lifespan requirements

Precision tolerance

High-precision molds and tight-quality requirements will increase price but significantly improve long-term ROI.

How to Choose a Reliable Injection Mold Manufacturer

1. Engineering Capability

Review past mold designs and technical documentation.

2. Quality Certification

ISO 9001 ensures process standardization.

3. Material Knowledge

Expertise in engineering plastics and reliability testing.

4. Equipment Level

Check for CNC, EDM, wire-cut, CMM measurement, and hot runners.

5. Delivery & Communication

Fast response and engineering transparency reduce risk.

Guangdong Engineering Plastics Industries Group Co., Ltd. excels in all critical criteria.

Frequently Asked Questions (FAQ)

1. How long does injection mold manufacturing take?

Typically 2–6 weeks, depending on part complexity.

2. What is the lifespan of an injection mold?

From 100,000 to over 1 million cycles, depending on steel type.

3. Can you manufacture molds for small parts?

Yes—micro-molding capability is supported.

4. Do you provide mold design files?

Yes, full 2D/3D data and mold structure documentation are included.

5. Do you support mass production after mold manufacturing?

Yes—we offer complete injection molding services.