Why Partner with EnQi?

There are a huge numbers of precision machining parts manufacturers. Why should you choose us? Here are the top 3 reasons:

Proven Expertise

We provide professional service and the best quote for first-time buyers. Our engineers are happy to guide you through the design process. They have built up rich, deep experience from many previous projects, allowing them to efficiently handle complex and precision parts across several industries and provide rapid machining solutions.

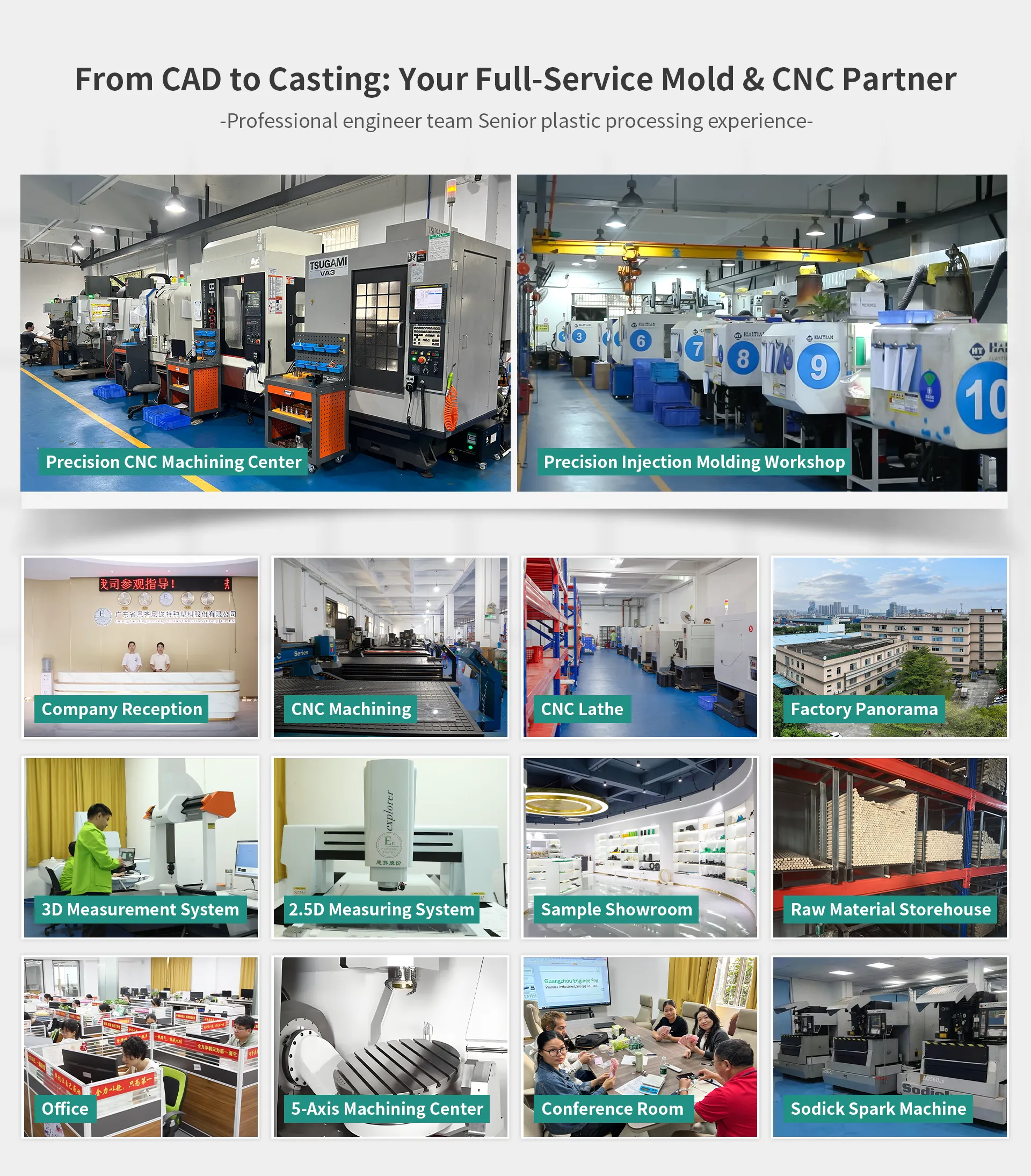

Advanced Equipment

EN boasts extensive in-house equipment for precision machining and rigorous testing. Our CNC milling, CNC turning, EDM, and other machining processes produce high-quality parts, which are meticulously inspected using a Hexagon CMM and an Olympus XRF analyzer. We guarantee that every part we deliver meets the highest standards.

Fast Turnaround

On average, we return quotes within 10 hours, ship machined parts within 7 days or less, and maintain a 99% on-time delivery and quality rate with our rapid machining services.

Types of Precision Machining That We Offer

Precision CNC Milling

Using imported multi-axis milling machines from the United States and Japan, as well as the top brand from China, we can guarantee CNC milling parts that are within the tolerance of +/-0.05mm, while also keeping critical dimensions under +/- 0.005mm.

Our team also has extensive experience creating precision parts for some of the most demanding industries in the world, including aerospace and medicine.

The 5-axis CNC milling machines come with an on-site inspection system that allows us to monitor the actual dimensions of a part during the milling process. The computer is able to automatically adjust the program and parameters to ensure that the parts are manufactured correctly.

Learn More →Our Precision Aluminum Machining Capabilities

At EN, we specialize in precision CNC machining of aluminum . Our CNC machines with powerful spindles allow us to cut aluminum at high speed—ideal for parts such as enclosures. In addition, using high RPM machines fitted with smaller cutters, we can also produce parts with a high-quality machined surface and fine details: aluminum reflectors and mold cores.

We have extensive experience in both rapid material removal and fine detailing. This allows us to produce a wide range of aluminum parts. From simple to complex, and from small to large, we can handle various requirements. Whether you need a quick-turnaround aluminum prototype or a high-volume order of custom parts, we offer flexibility and cost-effective solutions to meet your needs.

CNC Machining Materials

PEEK

A high-performance, heat-resistant plastic with excellent chemical resistance, commonly used in aerospace, medical, and automotive parts.

5 Advantages of Precision Machining

Precision machining is an essential manufacturing process that enables companies to produce the most delicate parts with the tightest tolerances imaginable. Here are just some of its main advantages over alternative approaches:

High Precision

As the name implies, precision molding offers unparalleled accuracy, producing consistent quality with every part that is produced.

Minimal Errors

Because precision machining uses CNC technology, it is largely automated and reduces the probability of error to a minimum.

Efficiency

Because of the automated nature of the process, precision CNC machining can produce parts very efficiently and with minimal workforce intervention.

Less Waste

Precision machining produces minimal waste, allowing to save on materials and maintain environmentally-friendly manufacturing practices.

Cost-Effective

The high-tech nature of the process also means that there's less waste, less labor, and a low chance of error, which makes it one of the most cost-effective manufacturing methods.

Put your parts into production today

Quality Control

At EnQi Manufacturing, quality is our top priority. We implement rigorous quality control measures throughout the entire manufacturing process to ensure that every part meets the highest standards of precision and reliability. Our comprehensive quality assurance system includes advanced inspection tools and techniques to maintain consistency and excellence in our products.

In-Process Inspections

Our quality control begins with in-process inspections, where each part is checked at various stages of production to ensure adherence to design specifications. This proactive approach helps identify and correct any issues early in the manufacturing process.

Final Inspections

Before any part leaves our facility, it undergoes a thorough final inspection to verify its quality and precision. We use advanced measurement tools and techniques to ensure that each part meets the required specifications and standards.

Precision Measurement Tools

We utilize a range of precision measurement tools, including Coordinate Measuring Machines (CMM), optical comparators, and laser scanners, to accurately measure the dimensions and tolerances of our CNC machined parts. These tools enable us to maintain tight tolerances and high precision in every component we produce.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification

Our commitment to quality is demonstrated by our ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification. This international standard ensures that our quality management system is effective and continuously improving, providing our customers with consistent, high-quality products.

Continuous Improvement

We believe in continuous improvement and regularly review our processes and practices to identify areas for enhancement. By investing in the latest technologies and training for our staff, we strive to maintain our reputation for quality and innovation.

Customer Reviews

Trusted by Innovative Companies

Industry Applications

Need Assistance? We're Here for You.

If you have any questions or need assistance, our team is ready to provide support 24/7. Reach out to us through any of the methods below.

Precision

Machining

FAQ'sPut your parts into production today.

All information and uploads are secure and confidential.