Need to quickly test out the market with low-volume parts? Or want to create large quantities of production parts? Then you can't go wrong with our plastic injection molding service. At EnQi, we produce high-quality prototype moldings from aluminum molds with quick turnaround times. Our customers can test out their designs for manufacturability, functionality and marketing, fast. We also offer plastic injection molding for your high-volume production needs.

2K+

CUSTOMERS

SERVED

29+

COUNTRIES

SERVED

1M+

PARTS

MADE

15+

YEARS

IN BUSINESS

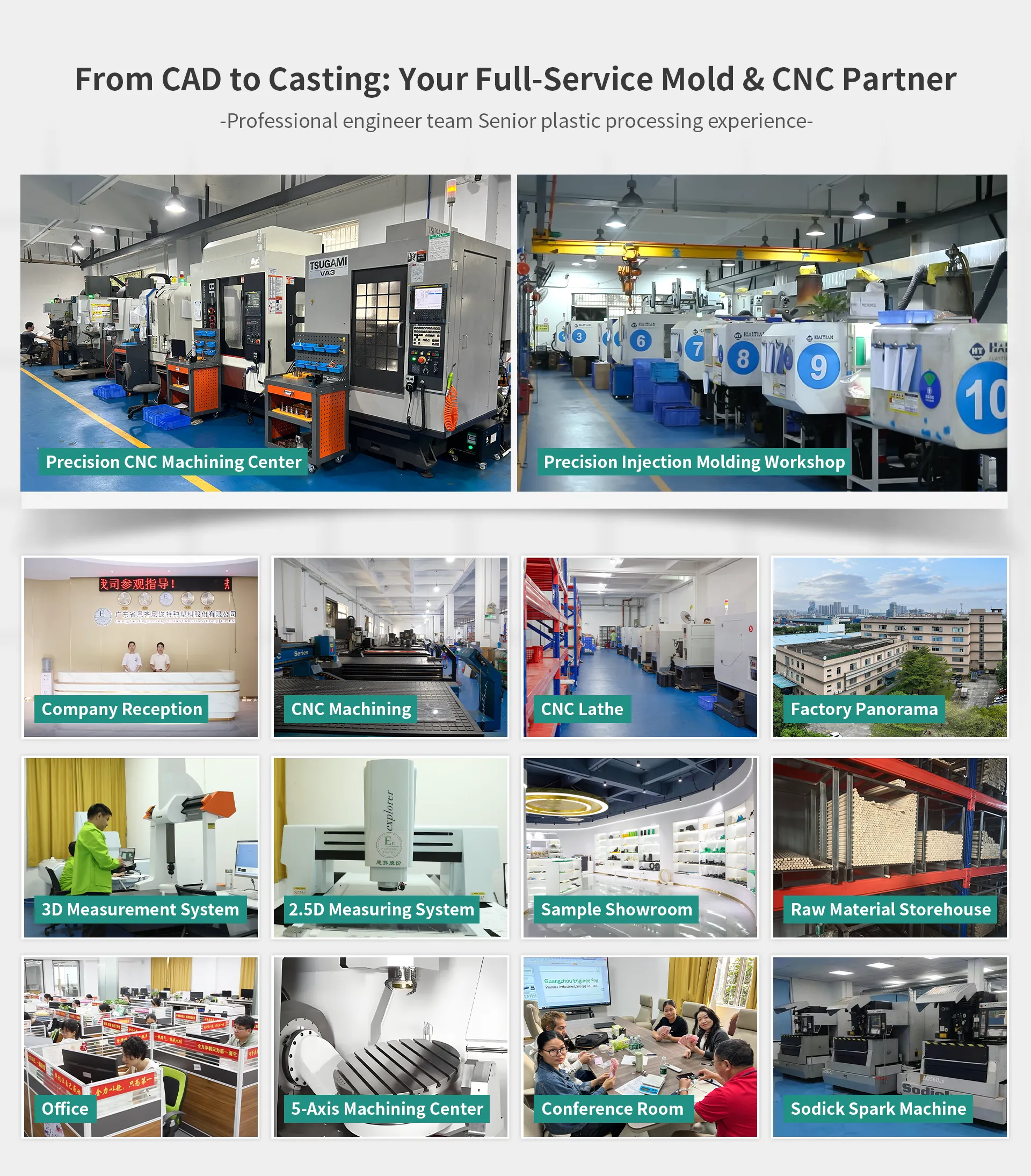

Why EnQi is your best option for plastic injection molding

With years of experience creating molded plastic parts for our customers, EnQi provides many advantages over other companies. We offer a truly end-to-end plastic injection molding service, from design to production, always guaranteeing the highest quality.

Here are four reasons why EnQi is your best option for plastic injection molding — whatever the parts, whatever the scale.

Mold Making

We can take care of both mold making and injection molding. That means we can oversee part manufacturing from end to end and easily scale up production if required.

Unlock the Quantity

Most plastic injection molding companies focus on mass production. But we are more flexible, offering low-quantity prototyping, mass production of 1m+ parts, and everything in between.

Reliable Quality

Our experienced engineers can kickstart your project with expert DFM analysis and mold making, before helping you decide on the best injection molding parameters for your parts.

Unlimited Capacity

In addition to our in-house facilities, we are partnered with an extensive plastic injection molding manufacturer network. Fleets of injection machines are ready for your order today.

Additional Plastic Injection Molding Options

Overmolding

Overmolding is a form of custom plastic injection molding during which the plastic injection molding company creates a part from multiple materials. The process adds an injection molded layer of material over an existing injection molded workpiece, producing chemically bonded parts made from multiple materials.

The overmolding process can be used to build layered parts from scratch or to add a resistant outer layer to existing plastic parts and tools, providing a more rugged exterior. Toothbrushes consisting of a solid plastic body and rubberized grip are a common example of an overmolded product.

Insert Molding

Insert molding is similar to overmolding, but the substrate is not necessarily plastic and does not have to be produced via injection molding. For example, insert molding can be used to add a plastic coating to a pre- fabricated metal part like a blade or threaded insert.

Common parts made by insert molding include sharp handheld tools, such as scalpels, which consist of a metal blade partially housed within a plastic handle. Insert molding is also frequently used to create products that incorporate bushings, clips, and fasteners.

Prototype Molding & Mass Production Molding

Delivered fast with 4 simple steps

Upload a CAD file

Simply upload your 3D models when you request a quote, along with any technical drawings, preferred materials, and finishing requirements. We'll take it from there.

Confirm Your Order

We'll assess your request, perform DFM analysis, and provide an estimate. If you're happy with the terms, we can get started on the plastic injection molding project right away.

Production

Our team of experienced engineers will get your custom plastic injection molding done fast, whether it's a one-off prototype or a larger order.

Delivery

We'll ship your injection molded plastic parts anywhere in the world. You'll get your shipment quickly, even if it's a large order of many units.

Injection Molding Materials

A diverse range of industrial-grade materials is available for molded parts, providing great flexibility for both prototyping and production. Materials include common plastics such as ABS, PC, PP, and PA, as well as high-performance, temperature-resistant options like PEI and PPS. Learn more about material selection tips and recommendations on our material guide page.

ABS

ABS (Acrylonitrile Butadiene Styrene) is a versatile thermoplastic polymer known for its strength, durability, and ease of processing. It is widely used in applications such as automotive parts, consumer electronics, and medical equipmen.

Injection Molding Plastic

Our plastic injection molding service supports the manufacture of parts in a range of molding materials. These include rigid plastics like ABS, flexible plastics like TPE, and mixed materials like PC-ABS. We can also obtain specialty materials and create custom material and pigment blends to suit your order.

Rigid plastics

The majority of injection molded parts are made from rigid thermoplastics. These include inexpensive and versatile plastics like ABS and PP, as well as naturally transparent plastics like PC and acrylic and high-strength plastics like POM. Other rigid plastics for injection molding include nylon, PET, and PS.

Plastic Injection Molding Finishes

The most convenient way to apply surface finishes to moldings is to perform any necessary finishing on the metal mold. In this way, we can give the moldings different surface finishes such as matte, high-gloss, and various textures. Secondary finishes — applied to the finished moldings — are also an option.

Matte

Plastic injection molding companies like EnQi can give a consistent matte finish to plastic injection molded parts — soft grip handles, for example — by carrying out techniques like sandblasting, chemical etching and EDM on the metal mold. The surface roughness of matte moldings typically ranges between 0.40 and 18.00 Ra µm.

Learn More About Plastic Injection Molding

What is plastic injection molding

Plastic injection molding is a manufacturing process mainly used to make plastic parts in large quantities. Used by many industries for a wide variety of parts, plastic injection molding produces more thermoplastic parts per year than any other plastic manufacturing process. The plastic injection process requires a metal mold and an injection molding machine. Plastic pellets are heated to melting point, then forced into the mold, where the material cools and solidifies, assuming the shape of the mold cavity. The most common materials for plastic injection molding are thermoplastics such as ABS, nylon, and acrylic. However, it is also possible to mold thermosets and elastomers. Plastic injection molding can produce parts in a range of sizes, from bottle caps to large automotive panels, but it is best suited to thin-walled parts, because thick sections of molded plastic are more likely to deform as they cool down inside the mold.

Quality Control

At EnQi Manufacturing, quality is our top priority. We implement rigorous quality control measures throughout the entire manufacturing process to ensure that every part meets the highest standards of precision and reliability. Our comprehensive quality assurance system includes advanced inspection tools and techniques to maintain consistency and excellence in our products.

In-Process Inspections

Our quality control begins with in-process inspections, where each part is checked at various stages of production to ensure adherence to design specifications. This proactive approach helps identify and correct any issues early in the manufacturing process.

Final Inspections

Before any part leaves our facility, it undergoes a thorough final inspection to verify its quality and precision. We use advanced measurement tools and techniques to ensure that each part meets the required specifications and standards.

Precision Measurement Tools

We utilize a range of precision measurement tools, including Coordinate Measuring Machines (CMM), optical comparators, and laser scanners, to accurately measure the dimensions and tolerances of our CNC machined parts. These tools enable us to maintain tight tolerances and high precision in every component we produce.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification

Our commitment to quality is demonstrated by our ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification. This international standard ensures that our quality management system is effective and continuously improving, providing our customers with consistent, high-quality products.

Continuous Improvement

We believe in continuous improvement and regularly review our processes and practices to identify areas for enhancement. By investing in the latest technologies and training for our staff, we strive to maintain our reputation for quality and innovation.

Industry Applications

Need help with your project?

If you need any help with your project, please contact us.