The Importance of Plastic Injection Mold Manufacturing

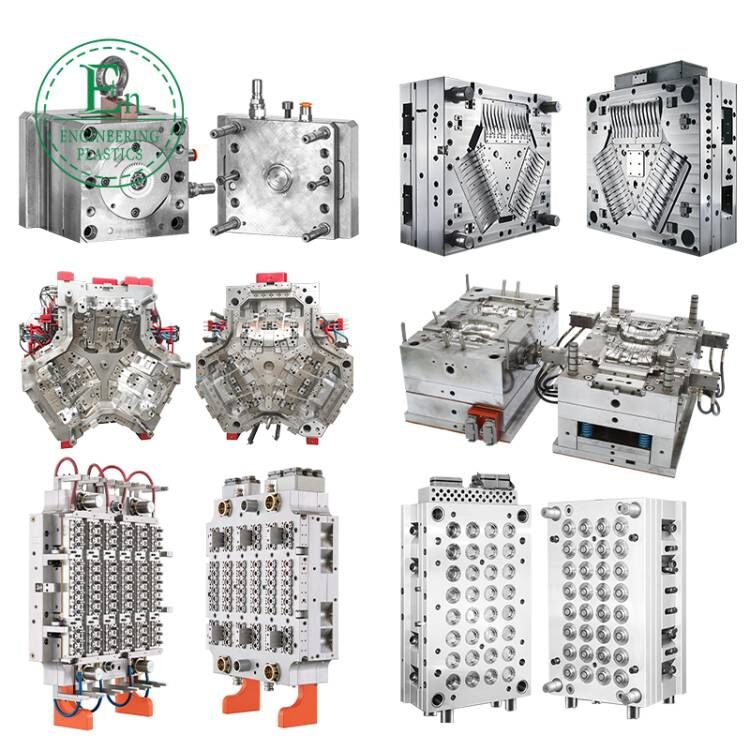

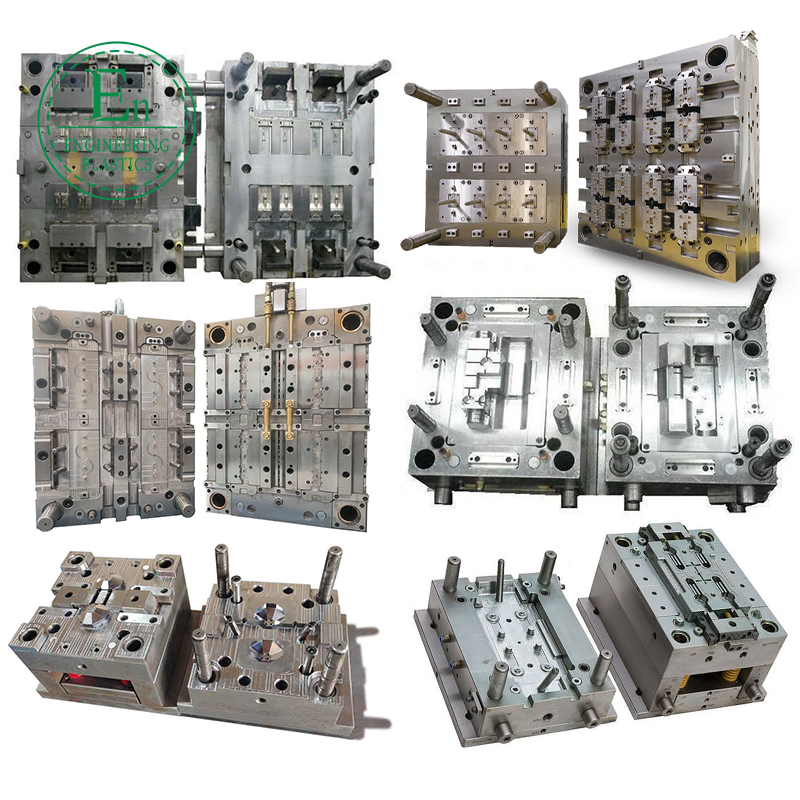

In industries where precision and efficiency are crucial, plastic injection mold manufacturing stands out as a key process. This innovative technique allows businesses to produce intricate and durable plastic components with unmatched accuracy. Whether creating custom plastic injection molds or navigating the injection molding process, the demand for high-quality, reliable manufacturing solutions has never been greater. For designers, engineers, and visionaries alike, these molds are the backbone of cutting-edge product creation.

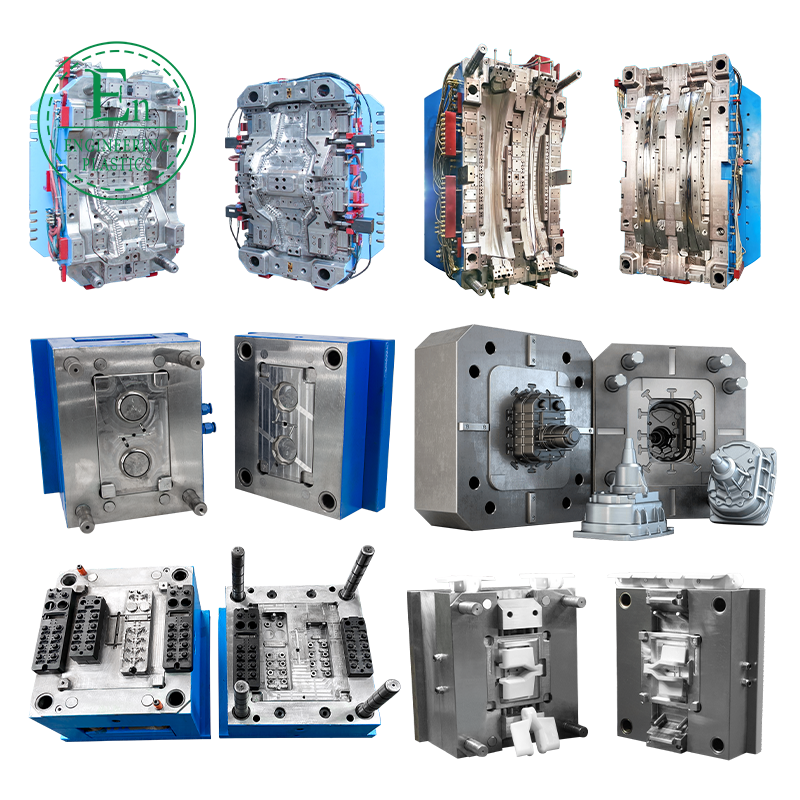

One of the primary challenges businesses face today is achieving efficiency without compromising performance. Plastic injection molding addresses this issue by offering a streamlined method to produce high-performance components. From automotive parts to consumer electronics casings, this method enables manufacturers to develop products that meet rigorous industry standards.

Customized Solutions for Unique Challenges

Customization is an essential aspect of modern manufacturing, and plastic injection mold manufacturing is no exception. Through the creation of custom plastic injection molds, businesses can cater to specific design and functional needs. This flexibility is particularly beneficial in industries such as healthcare, industrial machinery, and automotive, where precision and durability are non-negotiable.

The product range offered by engineering plastics solutions embodies the spirit of OEM/ODM customization. Specialized handles, intricate gears, durable brackets, and ergonomic housings—all crafted with high-performance plastics—showcase the versatility of injection molding. These components are not only designed for longevity but also for lightweight construction and wear resistance, meeting the demands of industries that value both durability and innovation.

Moreover, custom finishes and aesthetic elements further enhance the appeal of precision-molded parts. This attention to detail ensures that businesses can elevate their designs while maintaining operational functionality. The solutions cater to every stage of the manufacturing process, from prototyping to large-scale production, providing enterprises with tools to innovate boldly.

Transforming Business Efficiency Through Injection Molding

A significant challenge in manufacturing is balancing performance with scalability. Plastic injection mold manufacturing addresses this challenge by offering tailored solutions that adapt to a company's vision and requirements. By focusing on engineering excellence and full customization capabilities, businesses can transform their market impact while ensuring cost-effective production.

For industries like automotive and consumer electronics, injection molding promises precision and repeatability—ideal for crafting components like housings and structural elements. In healthcare, the process ensures the safe production of medical devices and tools. The beauty of injection molding lies in its adaptability, enabling manufacturers to turn their ideas into reality with minimal effort.

In conclusion, plastic injection mold manufacturing is not just a method—it's a game-changer in modern industrial processes. Companies investing in this technology are not simply creating products; they are building efficiency, innovation, and a competitive edge for the future. By embracing engineering plastics solutions with OEM/ODM customization capabilities, businesses can look forward to endless possibilities and groundbreaking designs tailor-made for success.