We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

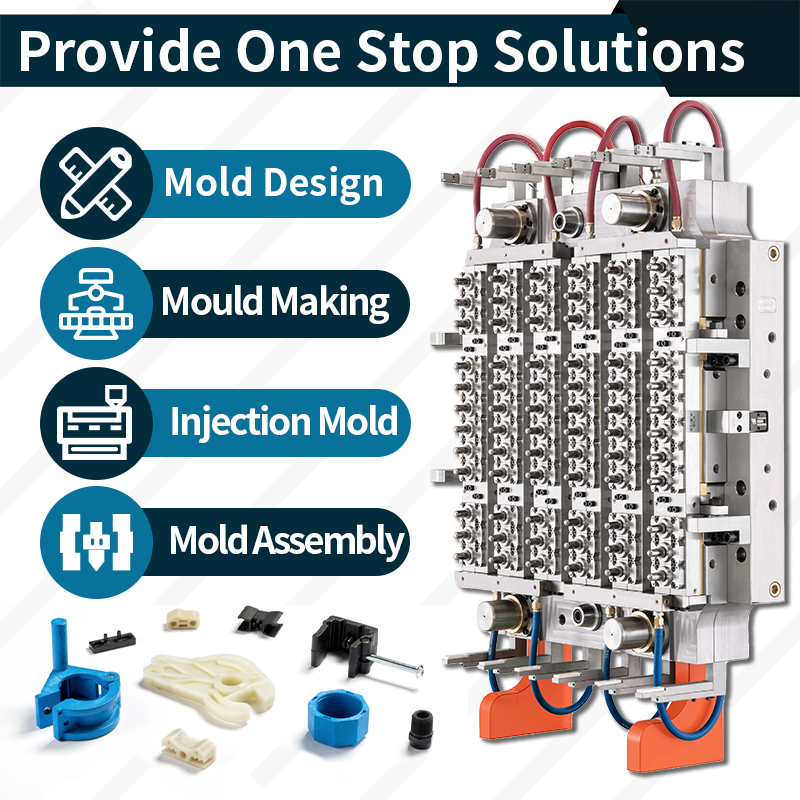

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

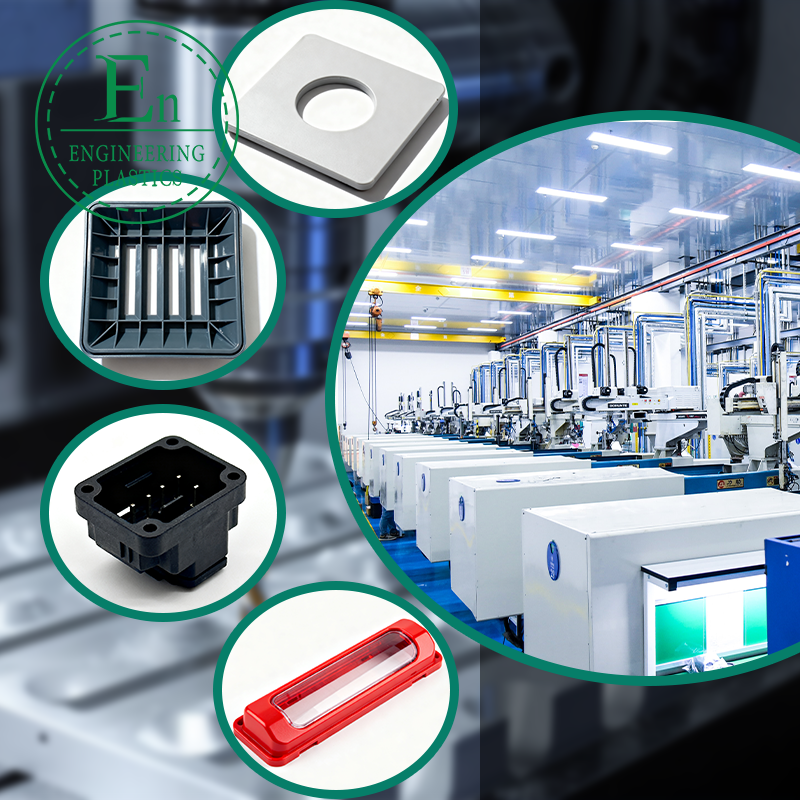

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

An Introduction to Inject Plastic Mold

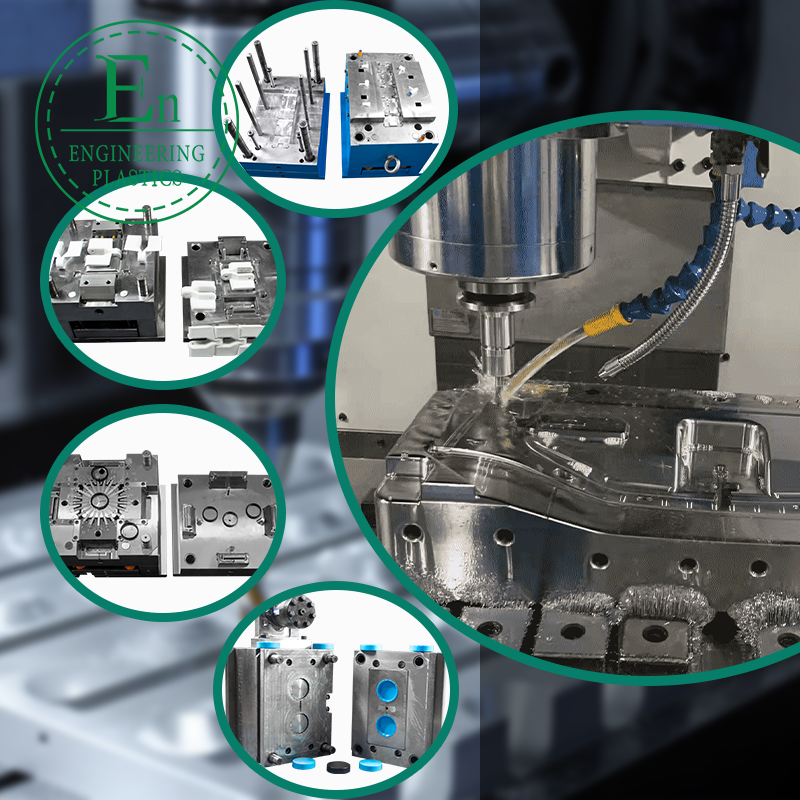

Inject plastic mold technology has revolutionized the manufacturing process, enabling industries to produce high-quality plastic components with efficiency and precision. These molds are essential tools used in various sectors, ranging from automotive to consumer goods. The latest innovations in inject plastic molds have significantly enhanced production capabilities by offering durability, precision, and versatility for creating complex structures and custom designs.

Features and Benefits of Advanced Plastic Molds

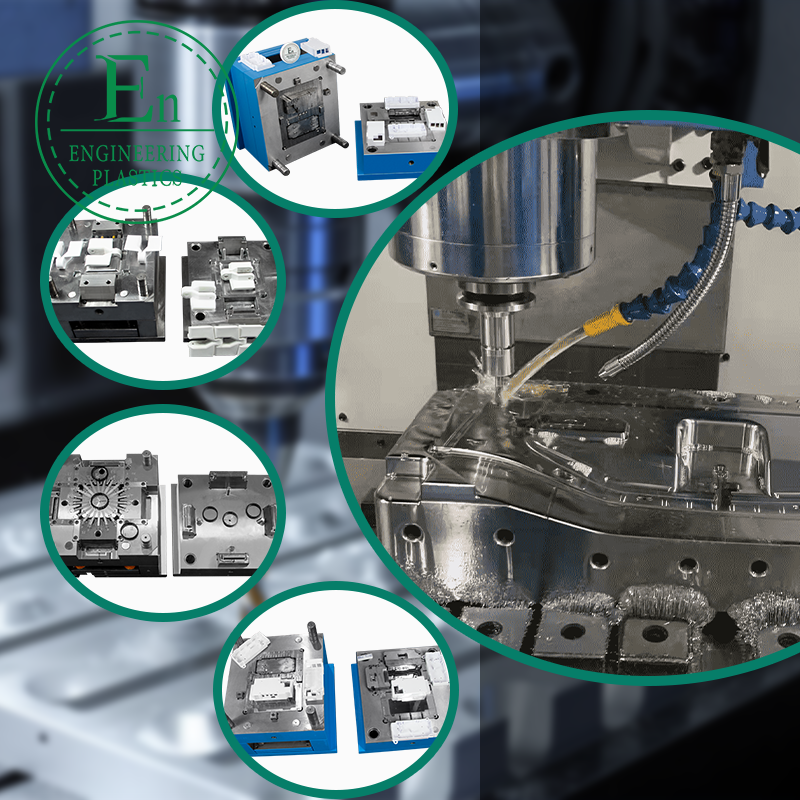

The cutting-edge molds showcased in the latest suite of innovations stand out due to their robust and durable design. Engineered using high-quality materials, these molds are built to perform consistently under the most demanding conditions. The high precision of these molds ensures flawless results, whether you’re crafting intricate designs or molding highly detailed components.

One standout feature is the multi-cavity configurations that allow for high-efficiency, large-scale production without sacrificing quality. These configurations optimize productivity and enable manufacturers to meet substantial production demands while maintaining impeccable standards. Advanced ejector systems integrated into some of these molds further streamline the process by facilitating seamless product removal, thereby reducing cycle times and improving manufacturing efficiency.

Furthermore, these molds are equipped with vibrant blue bases that provide stability and ensure smooth integration into existing machinery setups. The precision alignment of these molds is another highlight, as it minimizes waste and maximizes raw material utilization, reflecting a commitment to sustainable practices that are crucial in today’s manufacturing landscape.

Why Choose Inject Plastic Molds?

Inject plastic molds represent the pinnacle of sophistication in manufacturing tools. They offer versatility for handling various requirements, whether you’re producing prototypes or scaling your production line. The ability to cater to customized orders ensures that every requirement is addressed with perfection, making these molds a valuable asset for businesses looking to innovate and excel.

The factory behind these molds is equipped to handle diverse inquiries and offers personalized consultations to guide clients in selecting the ideal solution for their specific needs. With a commitment to delivering premium-grade components consistently and efficiently, this facility exemplifies top-tier molding expertise.

Whether it’s for intricate designs or high-volume production, inject plastic molds are designed to elevate manufacturing to the next level. Their durability, precision, and adaptability make them a stylish and sophisticated answer to modern manufacturing challenges. Inquiry-ready and unmatched in performance, these molds are an excellent investment for businesses aiming to lead in their industries.

Let these molds be the driving force behind your production success, offering unparalleled quality and reliability that meets the demands of today’s competitive market.