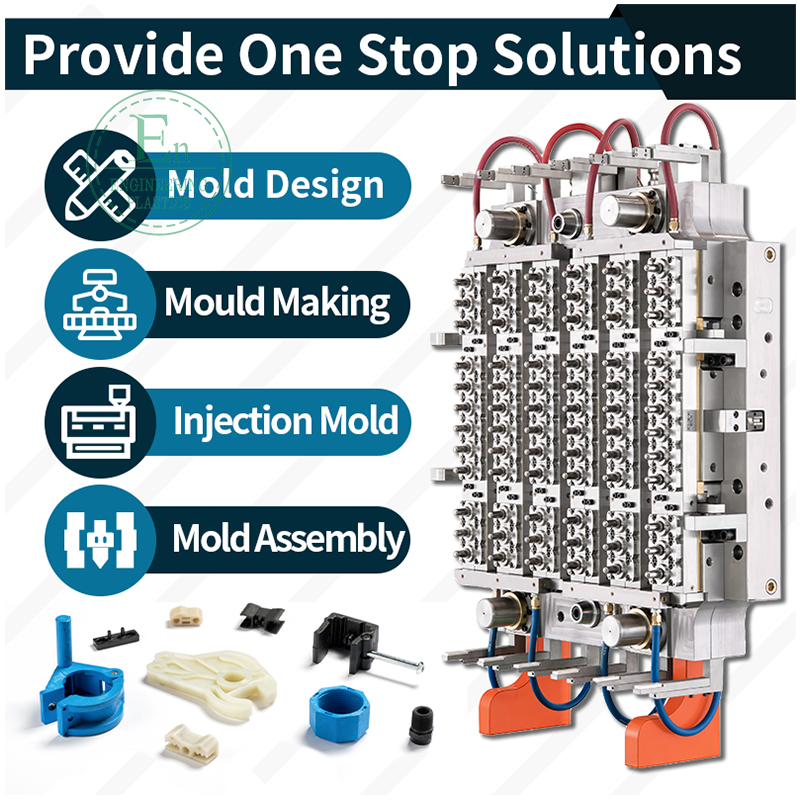

Injection Mold Design for Complicated Geometries: Economical Options for Manufacturers Worldwide

Businesses in Europe and the US need partners who can supply dependable injection mold design in the increasingly competitive global manufacturing industry, particularly for items with complex architecture. The accuracy, robustness, and efficiency of injection molds have a direct impact on product quality and production costs, whether they are used to make automotive components, industrial parts, medical devices, or bespoke consumer goods.

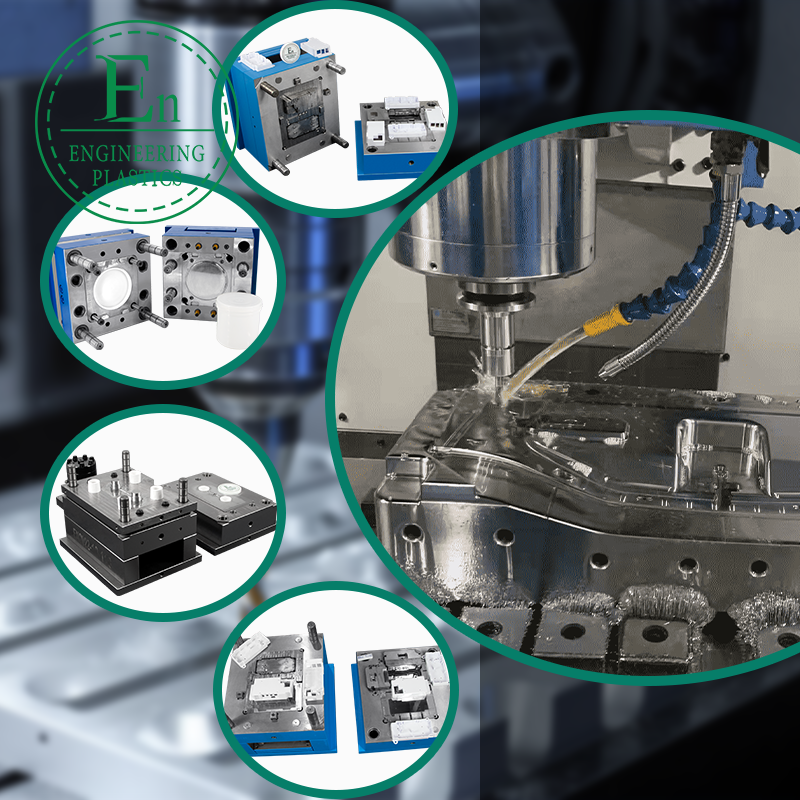

In order to help businesses maximize productivity, cut waste, and expedite product development cycles, Guangdong Engineering Plastics Industries Group Co., Ltd. specializes in providing injection mold design for difficult geometries and provides affordable injection mold design services.

The Significance of Injection Mold Design for American and European Manufacturers

For plastic components, injection molding is still the most economical method of mass production. However, the mold itself is the primary factor that determines both cost and quality.

- guarantees a constant level of product quality

- reduces the duration of cycles

- minimizes the wasting of materials

- prolongs the life of mold

- improves the performance of the product

- lowers production costs over the long run

A poorly constructed mold is not an option for businesses in the US and Europe, where productivity, accuracy, and compliance demands are high.

Difficulties in Creating Injection Molds with Complicated Geometries

Manufacturers frequently need complex shapes, undercuts, thin walls, distinctive textures, and multipurpose structures as items becoming increasingly complex. Mold design presents special difficulties for these complex components.

Components of Thin Walls

Although thin walls reduce product weight and material efficiency, deformation must be prevented through sophisticated testing, gate design, and cooling path optimization.

Internal Cores & Undercuts

Collapsible cores, inserts, or multi-slide mechanisms are necessary for parts with internal locking characteristics in order to guarantee full ejection.

Complexity of Multi-Cavity Mold

Multi-cavity molds might be necessary for mass manufacturing; this makes it much more difficult to guarantee consistent filling and ideal cooling.

Problems with Heat Distribution

Inadequate temperature control causes sink marks, bending, and low yield rates because complex geometries frequently retain heat.

Before cutting steel, our experts at Guangdong Engineering Plastics Industries Group Co., Ltd. address these issues using Moldflow analysis, DFM evaluations, and sophisticated simulation tools, lowering the risk of redesign and guaranteeing production success.

Essential Elements of Designing High-Performance Injection Molds

For complex geometries, a good mold necessitates careful consideration of engineering factors that affect manufacturing reliability, durability, and cycle time.

Enhanced Parting Line and Gate Architecture

Effective separation line preparation guarantees simple mold release and minimizes aesthetic flaws.

Selecting Steel with High Precision

Depending on the needs of the customer's product, we select from a wide variety of international steel alternatives (P20, H13, 1.2344, S136, 8407, etc.).

Engineering Cooling Systems

Cycle time can be shortened by up to 30% with a well-designed cooling system. We use:

- Conformal cooling

- Inserts for baffles

- sophisticated water-line distribution

Structural Simulation & Moldflow

Prior to creating a mold, we do:

- Analysis of flow

- Prediction of packing pressure

- Warpage identification

- Optimization of gate location

This guarantees that the mold will be very productive with little danger.

Economical Injection Mold Design Services That Lower Your Overall Production Costs

The long-term overall cost is frequently more important to European and American buyers than the initial mold price.

Our affordable injection mold design services concentrate on:

Minimizing Mold Alterations

Precise preliminary analysis reduces rework and guarantees a quicker start-up of production.

Reducing the Cost of Maintenance

Optimized cooling and premium steel minimize wear, prolonging the life of the mold.

Enhancing Cycle Effectiveness

Cycle times are shortened by improved cooling, flow pathways, and gate design, which lowers production costs by 10–40%.

Avoiding Downtime in Production

The risk of failures is reduced by sturdy structural design, accurate tolerances, and dependable cooling.

Case Studies: Mold Projects with Complex Geometries That Worked

Examples of mold modification services offered to customers in the US and Europe are shown below.

Case Study 1: German Automobile Interior Component

Client Pain Point: The client required a thin-wall, lightweight car interior panel with intricate texture patterns and a high degree of accuracy.

Our Approach:

- Moldflow simulation was used to maximize gate placement.

- 1.2344 hardened steel was used to construct a multi-cavity steel mold.

- Advanced conformal cooling channels were integrated.

Outcomes:

- 35% reduction in cycle time

- No problems with warpage

- Lifespan of more than 120,000 shots without significant maintenance

Case Study 2: Medical Device Shell (USA)

Client Pain Point: A medical enclosure with extremely thin walls and intricate internal locking mechanisms needed a very accurate mold.

Our Approach:

- Perfect interior forms were achieved by using collapsible cores.

- A tolerance of ±0.02 mm was guaranteed for all crucial dimensions.

- Upon request, FDA-compliant goods were supplied.

Outcomes:

- 40% decrease in the scrap rate

- Enhanced effectiveness of assembling

- Clean, flash-free surfaces were attained.

Case Study 3: Industrial Equipment Housing (United Kingdom)

Client Pain Point: Large, sturdy housing with heavy structural ribs that must resist deformation.

Our Approach:

- Reinforced mold base design

- Installed dual cooling circuits

- Used hardened H13 steel for longevity

Outcomes:

- Deformation reduced by 28%

- Production output increased by 20%

Reasons for Selecting Guangdong Engineering Plastics Industries Group Co., Ltd.

Our capability matches the performance expectations of Western markets.

1. Proficiency in Complicated Geometries

- Automotive components

- Medical devices

- Industrial-grade housings

- Consumer electronics

- Custom OEM/ODM solutions

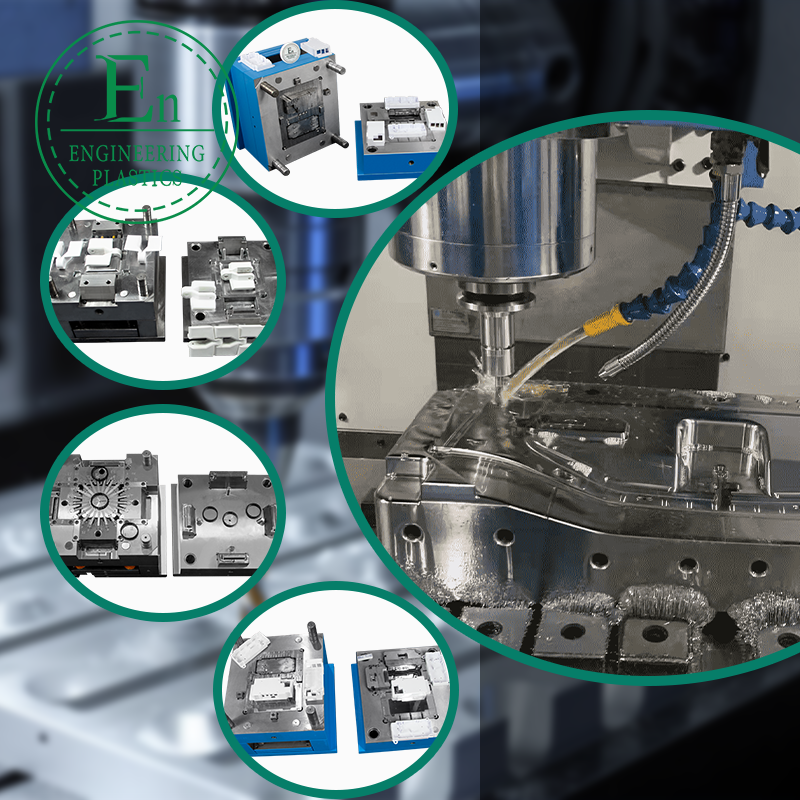

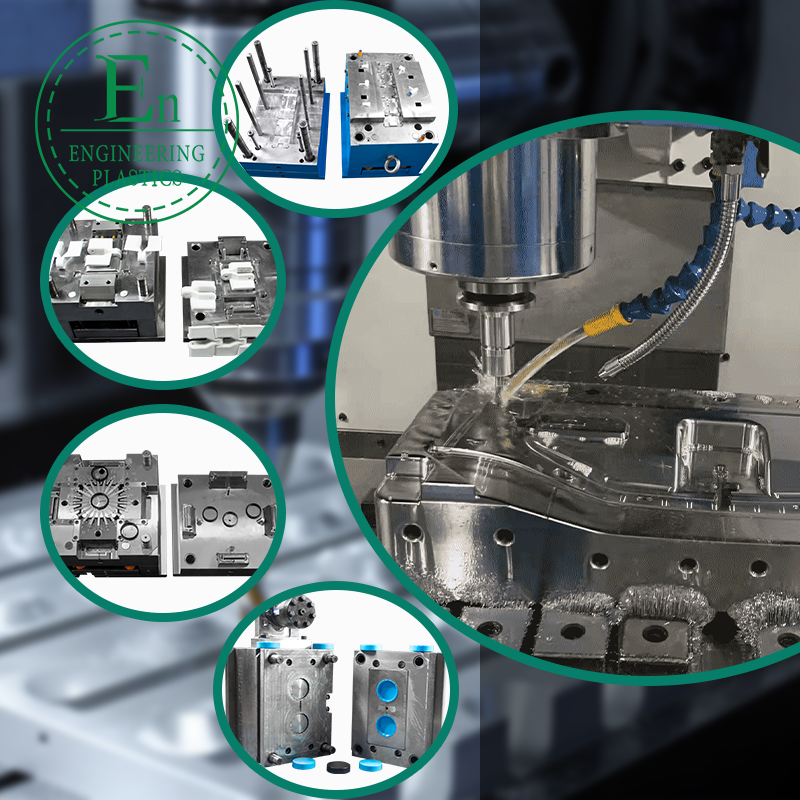

2. Advanced Engineering & Simulation Tools

CAD/CAM, UG, ProE, SolidWorks, Moldflow, CNC machining.

3. Efficient Communication & Western-Standard Project Management

- DFM reports

- Weekly progress updates

- Transparent timelines

- Fast technical response

4. Competitive Pricing Without Sacrificing Quality

European-level quality at significantly lower cost.

5. Fast Lead Times

In-house machining dramatically reduces delivery time.

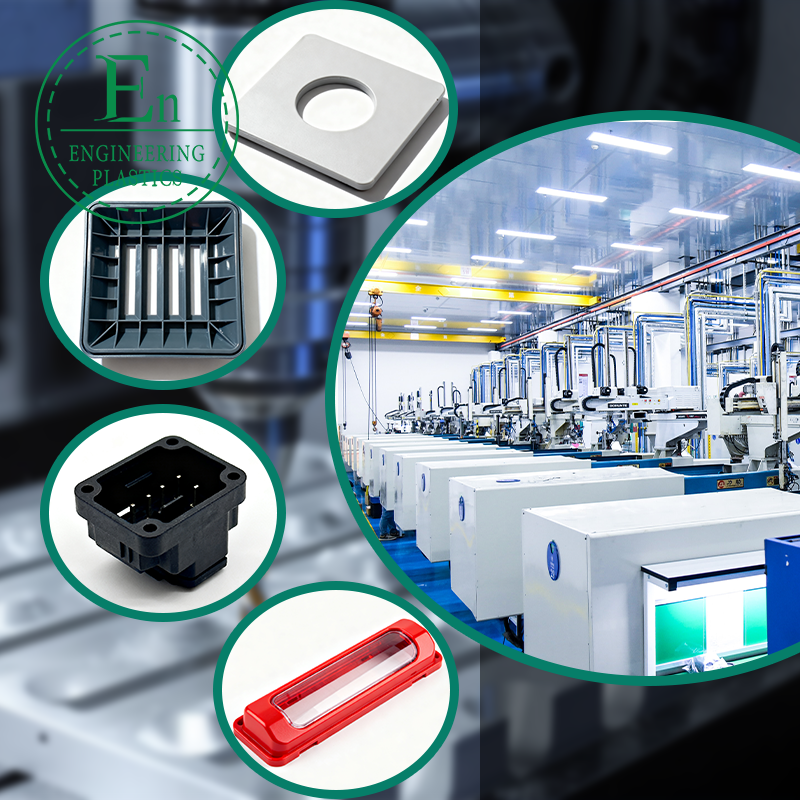

Industries Served

Automotive

Complex interior and exterior structural parts.

Medical

Thin-wall casings, precision components, sterile-grade materials.

Industrial Equipment

Durable housings, connectors, functional engineered parts.

Consumer Products

Appearance goods, multi-cavity molds.

The Mold Customization Process

Step 1 – Customer Consultation & DFM Analysis

Client provides drawings → we provide DFM & risk assessment.

Step 2 – Moldflow Analysis & Structure Design

We optimize runners, gates, cooling, parting lines.

Step 3 – Precision Mold Fabrication

CNC machining, EDM, wire-cutting, polishing.

Step 4 – Mold Trial & Sample Delivery

T0–T3 sampling with reports.

Step 5 – Mold Shipping or Mass Production

We ship molds or produce molded parts.

Conclusion — Partner with a Reliable Mold Design Expert

A well-engineered mold determines efficiency, quality, and long-term profitability. If your business requires injection mold design, mold design for complex geometries, or cost-effective mold engineering, choosing a reliable partner is essential.

Guangdong Engineering Plastics Industries Group Co., Ltd. delivers the expertise and engineering support required by European and American manufacturers.

Call to Action:

Contact us for a free DFM review and mold design consultation.

Email: sales@gz-plastics.com

Website: https://gzplastics.com/