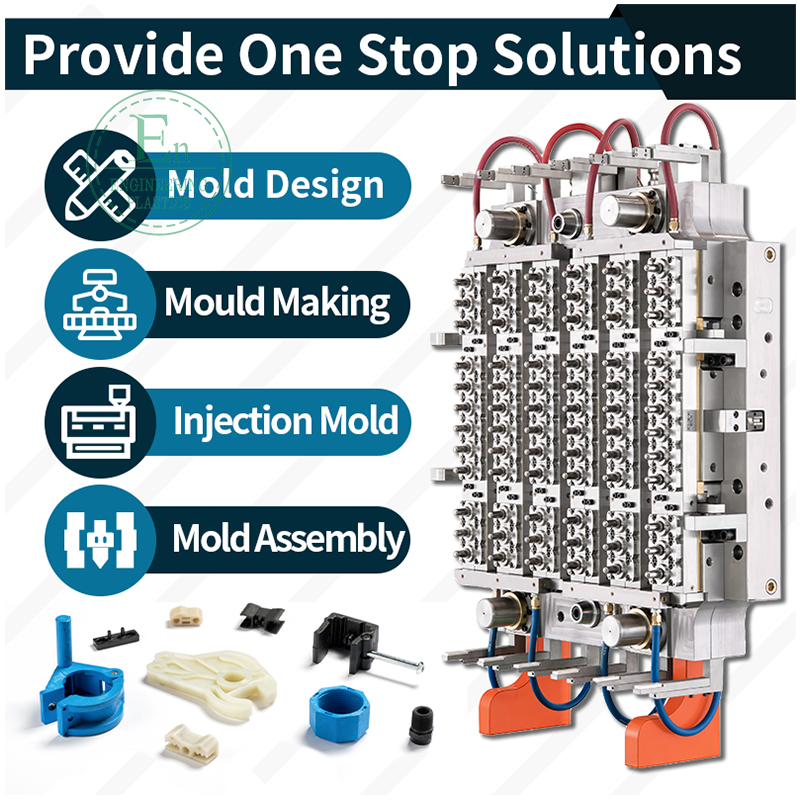

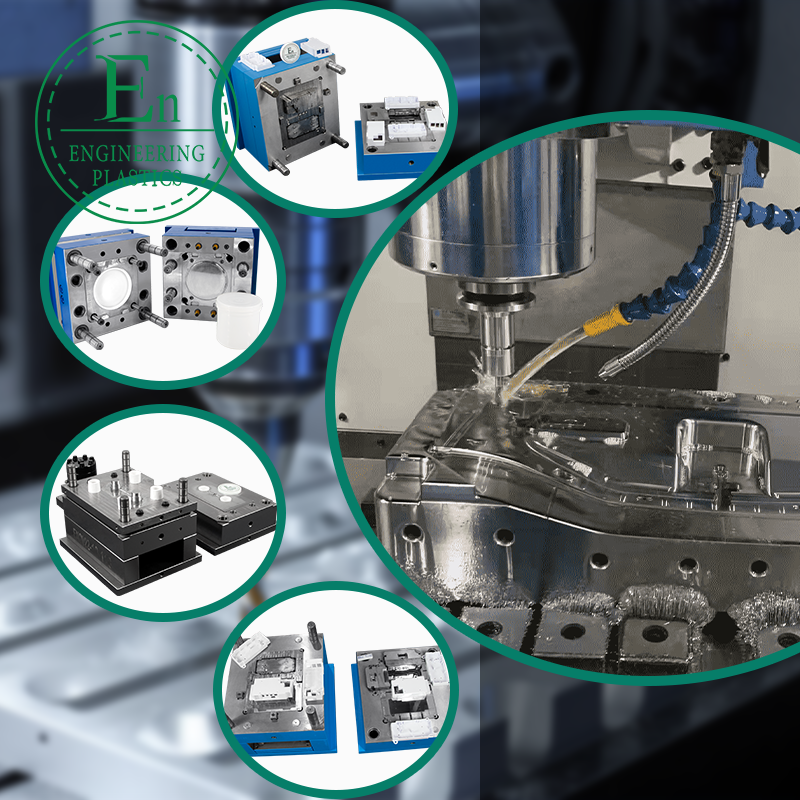

Mastering Mold Design for Precision Engineering Plastics

In the world of manufacturing engineering plastics, Mold Design stands as a cornerstone for achieving high-quality, durable products. At Guangdong Engineering Plastics Industries Group Co., Ltd., we leverage our expertise in Mold Design to create customized solutions that meet the exacting standards of industries worldwide. Our senior engineers, with 15-25 years of hands-on experience, ensure that every Mold Design process is tailored to produce components like gears, pulleys, and sealing rings with unparalleled precision.

The Fundamentals of Effective Mold Design

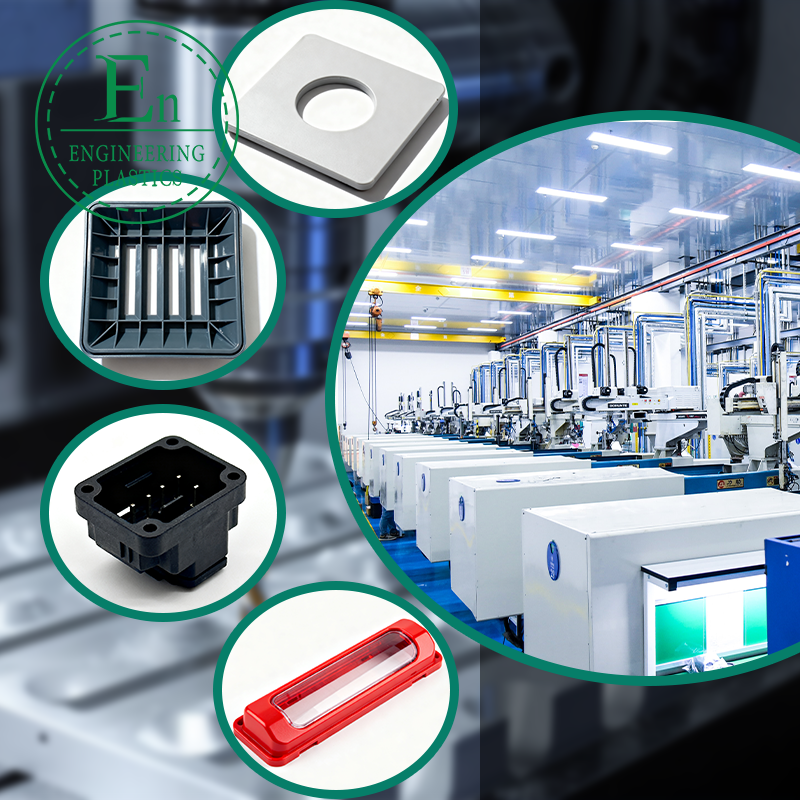

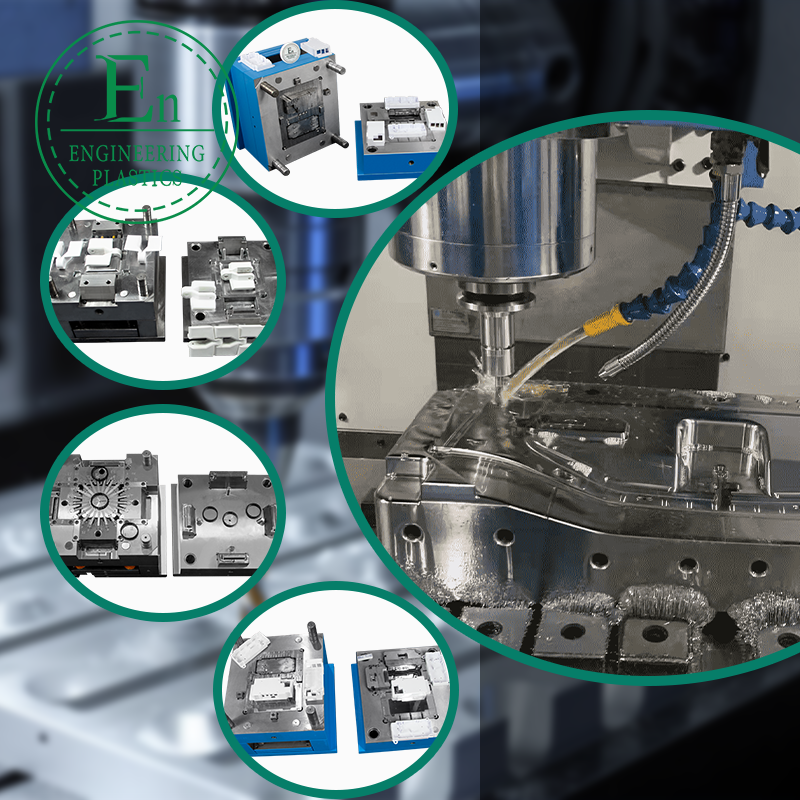

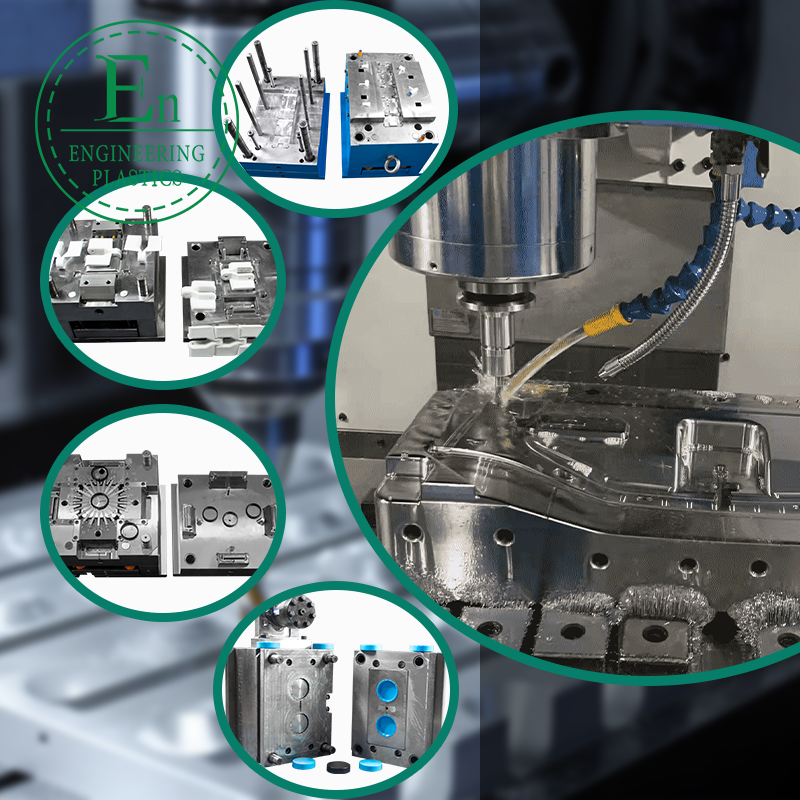

Mold Design begins with a deep understanding of material properties and application requirements. For instance, when working with advanced materials such as PEEK, PPS, Nylon, ABS, and PTFE, the Mold Design must account for factors like thermal expansion, shrinkage rates, and flow characteristics. Our team at Guangdong Engineering Plastics Industries Group Co., Ltd. employs state-of-the-art CAD software to simulate the molding process, minimizing defects and optimizing cycle times. This meticulous approach in Mold Design not only enhances product integrity but also reduces production costs for our clients. By focusing on ergonomic and efficient Mold Design, we deliver prototypes that transition seamlessly into full-scale manufacturing.

Customization and Innovation in Mold Design

Personalized Mold Design is at the heart of our services. Whether you're developing bearings for automotive applications or custom sealing rings for medical devices, our comprehensive research and development capabilities allow us to innovate beyond standard solutions. With a global footprint exporting to the USA, UK, Canada, Germany, and more, we've built a reputation for Mold Design that supports diverse market needs. Our engineers collaborate closely with clients to refine Mold Design iterations, incorporating feedback to achieve optimal performance. This client-centric Mold Design philosophy ensures that each project aligns with specific operational goals, from durability in harsh environments to compliance with international standards.

Why Choose Our Expertise in Mold Design

Selecting the right partner for Mold Design can transform your product development lifecycle. At Guangdong Engineering Plastics Industries Group Co., Ltd., our proven track record in manufacturing a wide array of engineering plastic products underscores our commitment to excellence. From initial concept through to final production, our Mold Design services integrate advanced techniques like multi-cavity molds and hot runner systems to boost efficiency. We've successfully supported international projects, earning trust through reliable, high-volume outputs that stand up to rigorous testing. By prioritizing sustainable practices in Mold Design, such as recyclable tooling materials, we help clients achieve eco-friendly manufacturing without compromising quality.

Future Trends in Mold Design for Engineering Plastics

Looking ahead, Mold Design is evolving with technologies like 3D printing for rapid prototyping and AI-driven optimization. At our company, we're at the forefront, integrating these innovations to future-proof our Mold Design processes. This forward-thinking approach not only accelerates time-to-market but also opens doors to complex geometries that were once challenging. As demands for lightweight, high-performance plastics grow, our expertise in Mold Design positions us to lead in sectors like aerospace, electronics, and renewable energy. Partnering with Guangdong Engineering Plastics Industries Group Co., Ltd. means gaining a strategic ally in navigating these advancements, ensuring your products remain competitive on a global stage.

In summary, superior Mold Design is the key to unlocking the full potential of engineering plastics. With our dedicated team and expansive capabilities, we're ready to bring your visions to life.