How to Choose the Right Injection Mold Service Provider for Your Project

Injection molding plays a vital role in modern manufacturing, especially for industries such as automotive, medical devices, consumer electronics, and industrial equipment. Selecting the right injection mold service provider is not simply a purchasing decision—it is a long-term strategic partnership that directly impacts product quality, delivery timelines, and overall competitiveness in global markets.

For European, American, and Russian B2B buyers, working with a reliable custom injection molding factory ensures consistency, scalability, and cost control. This guide explains exactly how to evaluate and choose the best injection molding partner for your business needs.

Why Choosing the Right Injection Molding Partner Matters

Injection molding is a capital-intensive process involving mold design, tooling, material selection, and mass production. Mistakes in supplier selection can lead to:

- Poor part quality and high rejection rates

- Mold rework or premature tool failure

- Delays in production and market launch

- Hidden costs due to inefficient processes

A professional injection molding partner acts as an extension of your engineering and supply chain teams, helping you reduce risk while improving manufacturing efficiency.

Understand Your Injection Molding Requirements First

Product Design and Complexity

Before contacting suppliers, clearly define:

- Part geometry and tolerances

- Wall thickness requirements

- Surface finish expectations

- Functional and aesthetic requirements

Complex designs require advanced mold flow analysis and experienced mold engineers.

Material Selection

Different injection molding materials impact performance and cost. Common materials include:

- ABS, PP, PE for consumer products

- Nylon, POM, PC for industrial applications

- Engineering plastics for high-strength or high-temperature use

A capable injection molding provider should offer material consulting to optimize performance and cost.

Production Volume and Scalability

Are you planning low-volume prototyping, medium-volume pilot production, or high-volume mass production? Choose a supplier with scalable injection molding capacity to support future growth.

Key Criteria for Evaluating an Injection Mold Service Provider

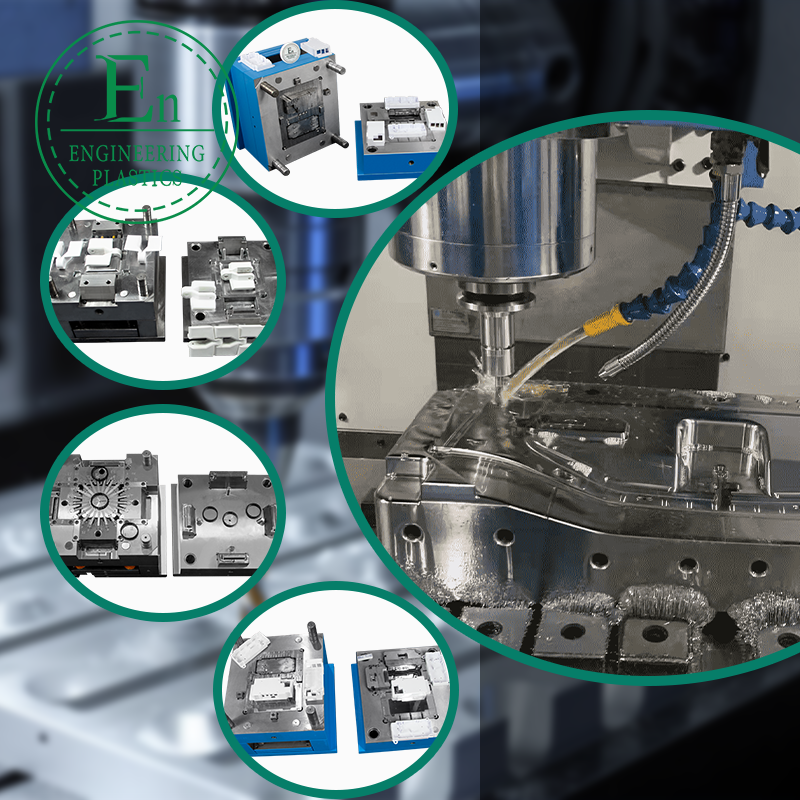

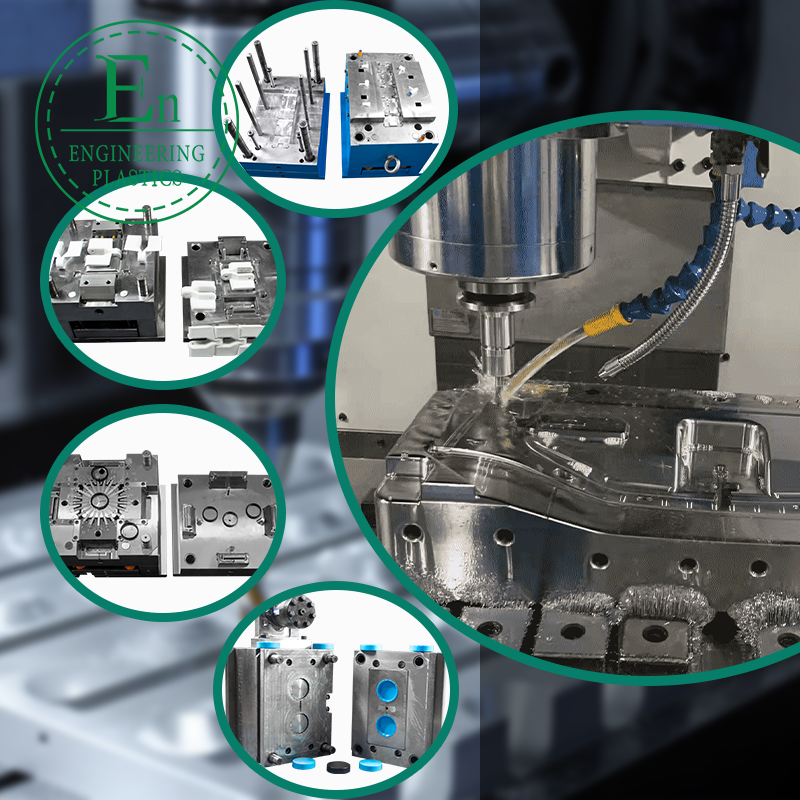

Mold Design and Engineering Capability

A strong injection mold service provider should offer:

- In-house mold design and DFM analysis

- Mold flow simulation to predict defects

- Optimization for cycle time and tool life

Early-stage engineering support reduces costly design revisions later.

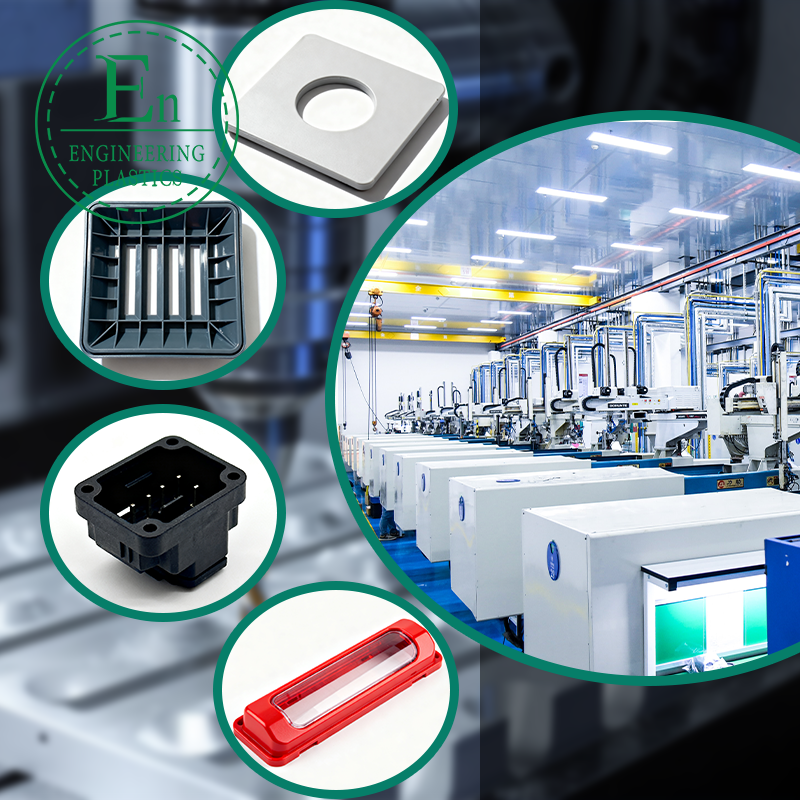

Manufacturing Equipment and Technology

Advanced injection molding factories invest in:

- CNC machining centers

- High-precision EDM and wire-cut machines

- Modern injection molding machines with automation

Technology directly affects part consistency and production efficiency.

Quality Control and Certifications

Quality assurance is critical for European and American buyers. Look for suppliers with:

- ISO 9001 / ISO 14001 certifications

- Incoming material inspection

- In-process and final inspection systems

- Full traceability and documentation

A reliable injection molding supplier treats quality as a system, not a final check.

Industry Experience and Use-Case Expertise

Industry-Specific Knowledge

Injection molding requirements vary by industry. For example:

- Automotive: tight tolerances, long tool life

- Medical: clean production, regulatory compliance

- Electronics: precision, cosmetic surface quality

An experienced injection mold service provider understands these differences and applies best practices accordingly.

Case Study Example

Case: European Industrial Equipment Manufacturer

A European OEM needed high-strength custom plastic housings with consistent dimensions. By working with an experienced injection molding factory, the customer achieved:

- 20% reduction in tooling maintenance costs

- Improved dimensional stability

- On-time delivery for multi-country distribution

This demonstrates the value of choosing a technically capable injection molding partner.

Cost Transparency and Total Cost of Ownership

Avoid “Low Price” Traps

The cheapest injection molding quote often leads to inferior mold steel, short mold life, and higher long-term production costs. Focus on total cost of ownership, including tool lifespan, cycle time, scrap rate, and maintenance.

Clear Quotation Structure

A professional injection mold service provider should provide:

- Transparent mold cost breakdown

- Unit pricing by volume

- Clear tooling ownership terms

Communication, Project Management, and Global Support

Communication Efficiency

For international customers, effective communication is essential. Your injection molding supplier should offer English-speaking project managers, regular progress reports, and fast response times.

Export and Logistics Experience

European, American, and Russian customers benefit from suppliers with export packaging expertise, experience with international shipping, and compliance with destination market standards.

Sustainability and Long-Term Partnership

Modern injection molding buyers increasingly value sustainable material options, energy-efficient production, and long-term cooperation rather than one-off orders. A trustworthy injection mold service provider invests in continuous improvement and customer success.

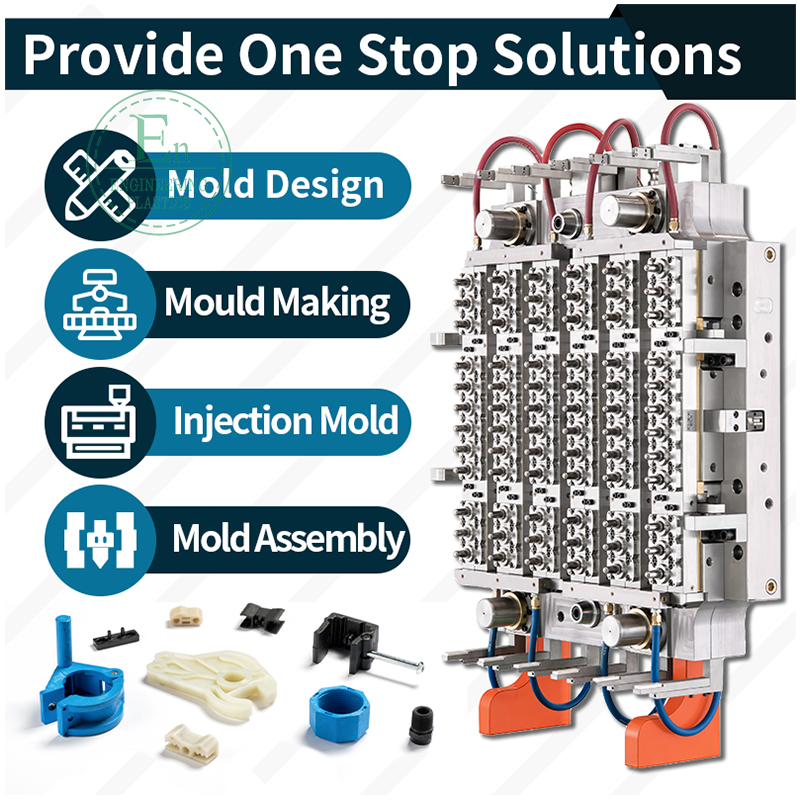

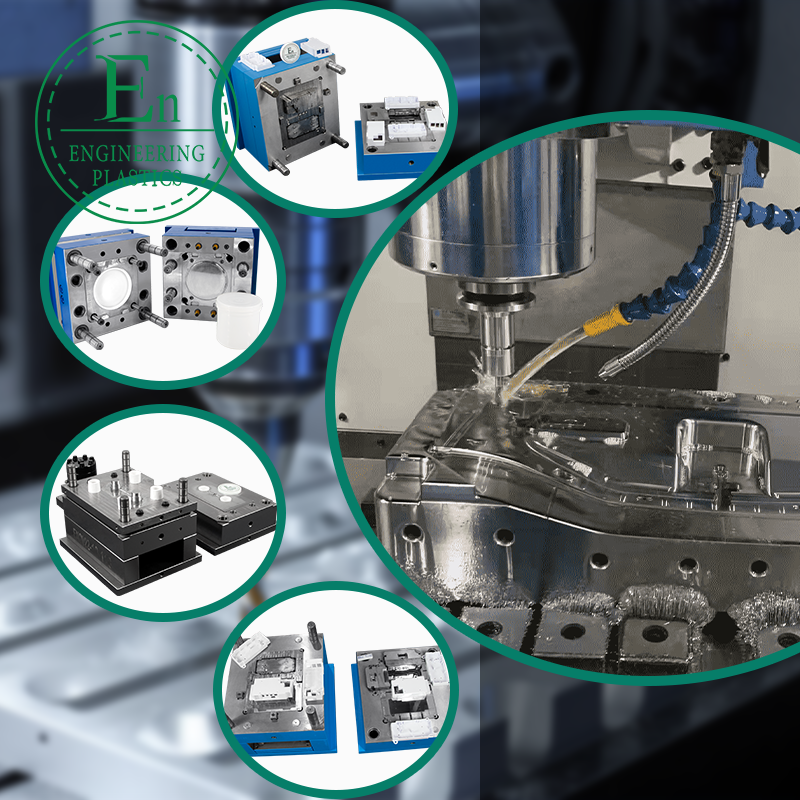

Why Choose Guangdong Engineering Plastics Industrial Group Co., Ltd.

Guangdong Engineering Plastics Industrial Group Co., Ltd. is a professional injection molding and mold customization manufacturer serving customers in Europe, the United States, and Russia.

Our Advantages

- Full-service custom injection molding and mold manufacturing

- In-house mold design, tooling, and mass production

- Strict quality control systems meeting international standards

- Rich experience in serving global B2B customers

- Competitive cost with stable long-term supply

Website: https://www.gz-plastics.com/

Email: sales@gz-plastics.com

We help customers transform product ideas into reliable, scalable injection molded solutions.

Conclusion — Make the Right Injection Molding Decision

Choosing the right injection mold service provider is a critical investment in your product’s success. By evaluating technical capability, quality systems, industry experience, and communication efficiency, you can build a long-term manufacturing partnership that supports growth and innovation.

If you are looking for a reliable, experienced, and cost-effective injection molding factory for European, American, or Russian markets, Guangdong Engineering Plastics Industrial Group Co., Ltd. is ready to support your project from concept to mass production.

Get Started — Contact Us Today

Ready to Start Your Injection Molding Project?

Get a fast review of your drawings, material recommendations, and a production-ready quote.

Request a Free Injection Molding Consultation

Email: sales@gz-plastics.com | Website: https://www.gz-plastics.com/