Which Injection Mold Service Offers the Fastest Turnaround Time?

In today’s highly competitive manufacturing environment, speed is no longer a luxury—it is a necessity. For companies sourcing injection molding services in Europe, the United States, and Russia, turnaround time can determine whether a product launch hits its window or gets delayed by weeks.

But “fast” should never mean risky. The best injection molding partners shorten lead times through strong engineering, in-house machining capacity, and disciplined project management—while keeping quality and repeatability stable for mass production.

Why turnaround time matters in injection molding

Injection molding often sits on the critical path of product development and production ramp-up. A delay in tooling immediately impacts prototype validation, pilot builds, and supply chain commitments.

Fast lead times are especially important when you are:

- Launching a new product (NPI) with a fixed release date

- Moving from prototype parts to stable mass production

- Replacing a damaged or end-of-life mold

- Responding to urgent design changes from your OEM or end customer

What counts as “fast” for injection mold turnaround

Turnaround time usually refers to mold lead time (design + manufacturing + first trial), not just the cycle time of part production. A practical benchmark depends on complexity, cavity count, steel selection, and surface finish requirements.

Typical benchmarks in the market:

- Conventional tooling: 6–10 weeks

- Rapid tooling: 2–4 weeks

- Ultra-fast prototype molds (simpler geometries): 7–14 days

For most B2B programs, a high-performing supplier can deliver reliable tooling in the 2–4 week range, including a documented first trial (T1) sample.

What determines injection molding turnaround time

1) Engineering and DFM speed

A fast supplier produces a clear DFM (Design for Manufacturability) quickly—highlighting risks such as sink marks, weld lines, gating choices, draft angles, and ejection feasibility. Faster DFM reduces design iterations and prevents rework later.

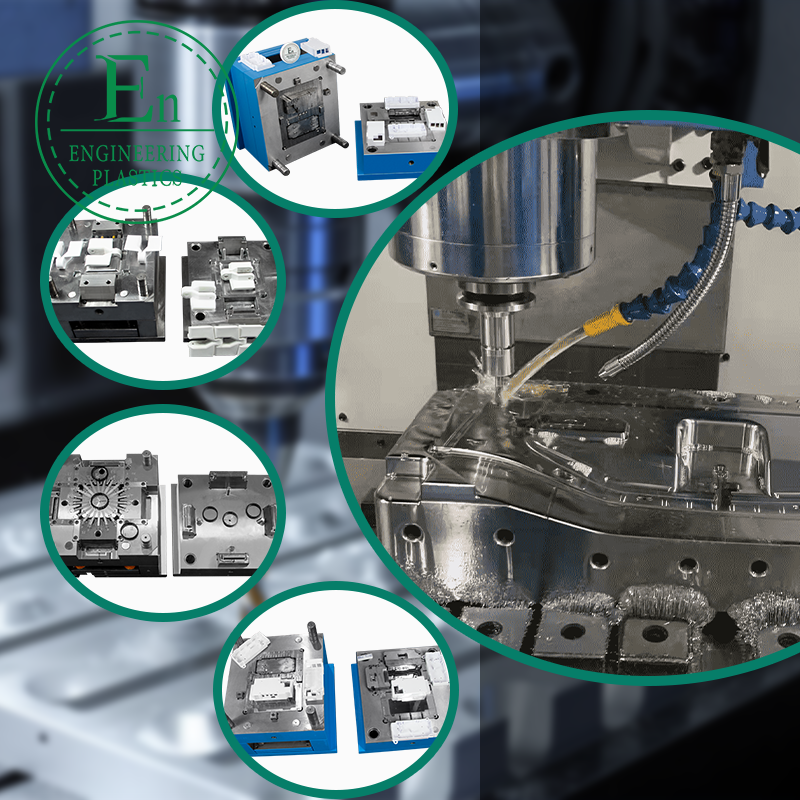

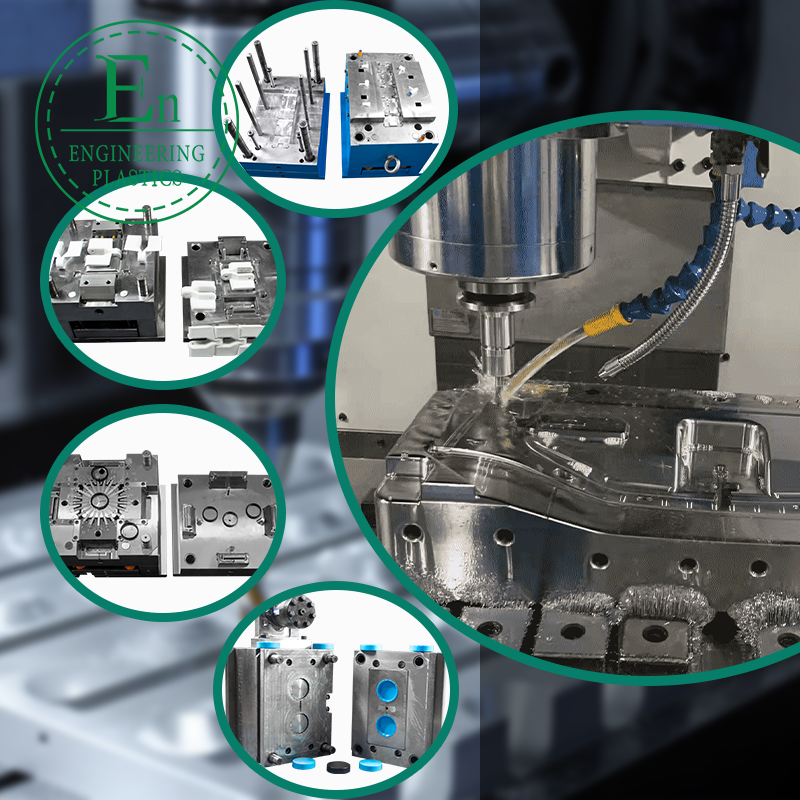

2) In-house machining capacity

The quickest injection mold service is usually the one that controls the entire tooling process in-house: CNC machining, EDM, wire-cutting, fitting, polishing, and assembly. Outsourcing key steps increases queue time and introduces scheduling uncertainty.

3) Standardized mold bases and components

Using standardized mold bases and globally recognized components (e.g., HASCO/DME equivalents) speeds up assembly and reduces procurement delays. It also helps future maintenance and spare part sourcing.

4) Project management and communication

Fast turnaround is as much about coordination as it is about machines. A dedicated project manager, clear approval checkpoints, and consistent documentation keep the timeline stable—especially for overseas buyers.

5) Trial, sampling, and modification workflow

Most lead-time surprises happen after the first trial. The best suppliers plan for fast modifications: they capture trial data, issue correction actions, and execute updates without losing days in handoffs.

Which regions offer the fastest injection molding turnaround

Europe

European mold makers are well known for precision and compliance, but lead times can be longer due to higher labor costs, capacity constraints, and limited flexibility for urgent builds. Many buyers see 6–12 weeks as typical for complex tools.

United States

US suppliers offer proximity and easier real-time collaboration. Turnaround can be competitive for simpler tools, but complex multi-cavity molds often face longer queues and higher costs that limit speed advantages.

China (export-oriented, engineering-led factories)

Many EU and US buyers choose China when speed and cost must be balanced. Export-oriented manufacturers with strong engineering and in-house capacity commonly deliver rapid tooling in 2–4 weeks for many projects—while still meeting global expectations for quality and repeatability.

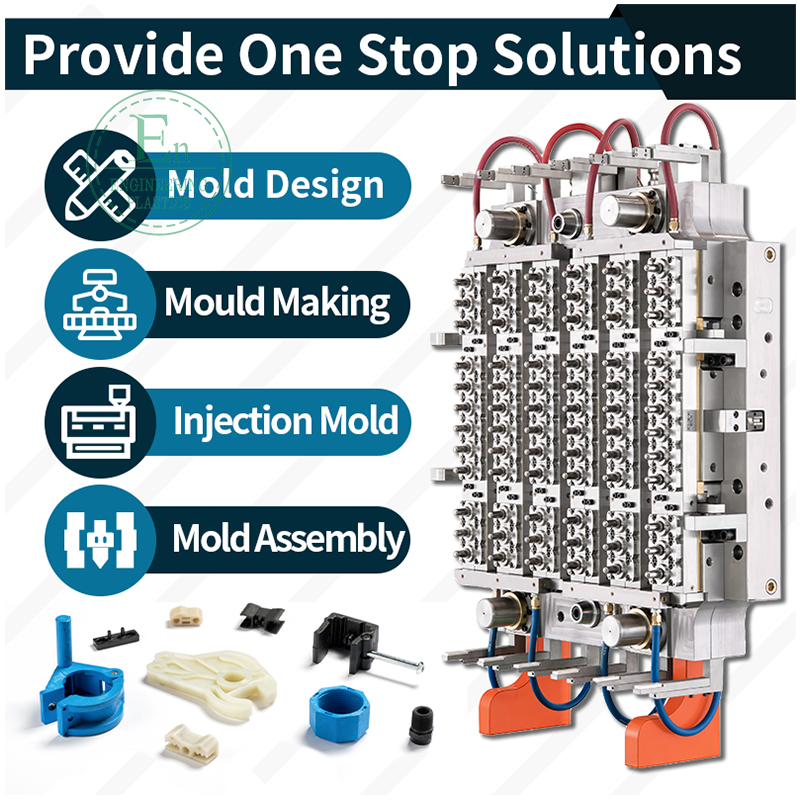

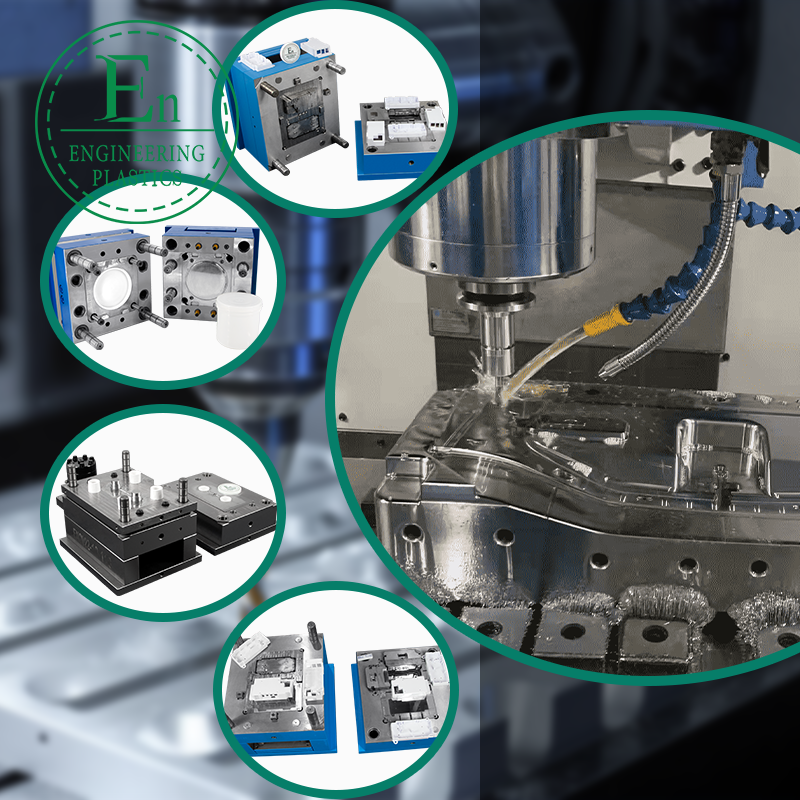

How Guangdong Engineering Plastics Industrial Group supports fast turnaround

Guangdong Engineering Plastics Industrial Group Co., Ltd. provides injection molding and custom mold manufacturing services for overseas markets, including Europe, Russia, and the United States. Our workflow is built to reduce tooling lead time while keeping quality stable for production.

What helps us move fast:

- Fast DFM feedback and design coordination

- In-house tooling manufacturing and controlled scheduling

- Export experience and documentation suited for B2B buyers

- Dedicated communication via email for international projects

Case study: fast mold delivery for a European consumer electronics program

Background

A Germany-based consumer electronics team needed a new housing mold for a launch schedule with no margin for delay. The part required a clean cosmetic surface and accurate internal features.

Challenges

- Tight delivery window

- Complex internal structure and gating considerations

- High surface finish expectations

Solution

We aligned DFM feedback early, finalized mold design quickly, and ran parallel machining steps where feasible. Trial data was captured and shared to shorten the correction loop.

Result

- Tooling lead time kept within a rapid schedule

- Customer validation supported on-time production ramp

- Stable repeatability for mass production requirements

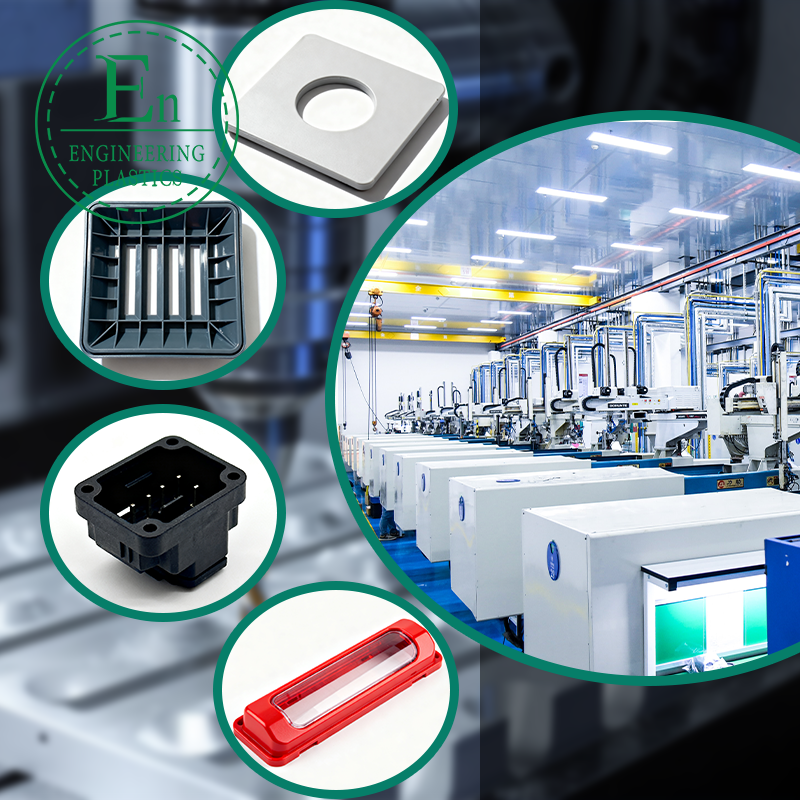

Who benefits most from fast injection molding services

Fast-turn injection molding is especially valuable for industries with tight launches, strict supply chain windows, or frequent design revisions:

- Automotive components

- Medical devices and housings

- Consumer electronics and smart hardware

- Industrial enclosures

- Home appliances

- IoT products and accessory ecosystems

Buyer pain points and practical solutions

Pain point: uncertain lead time

Solution: require a milestone schedule (DFM, design freeze, steel ordering, machining, fitting, T1, revisions) and ask how delays are reported and recovered.

Pain point: quality risk when moving fast

Solution: request steel grade confirmation, critical-dimension inspection plan, trial report, and process parameter documentation—so speed does not replace verification.

Pain point: communication delays across time zones

Solution: assign a single project owner on both sides, agree on response windows, and use structured change control for part revisions.

Fast injection molding supplier checklist

Before you choose a supplier claiming the fastest turnaround time, confirm:

- They manufacture molds in-house (not only assembly)

- They can deliver DFM feedback within 24–48 hours for most projects

- They share a realistic milestone schedule and update it consistently

- They have experience with EU/US quality expectations and export documentation

- They can support fast revisions after T1 without losing weeks in handoffs

Conclusion: speed that converts into business results

The fastest injection molding service is the one that combines engineering clarity, in-house manufacturing, disciplined project management, and repeatable quality. If your program has a fixed launch window, urgent replacement needs, or a prototype-to-production sprint, selecting the right partner can save weeks and reduce risk.

If you want a supplier that prioritizes fast, export-ready execution for Europe, Russia, and the United States, Guangdong Engineering Plastics Industrial Group Co., Ltd. is ready to support your next injection molding program.

Contact

Guangdong Engineering Plastics Industrial Group Co., Ltd.

Website: https://gz-plastics.com/

Email: sales@gz-plastics.com