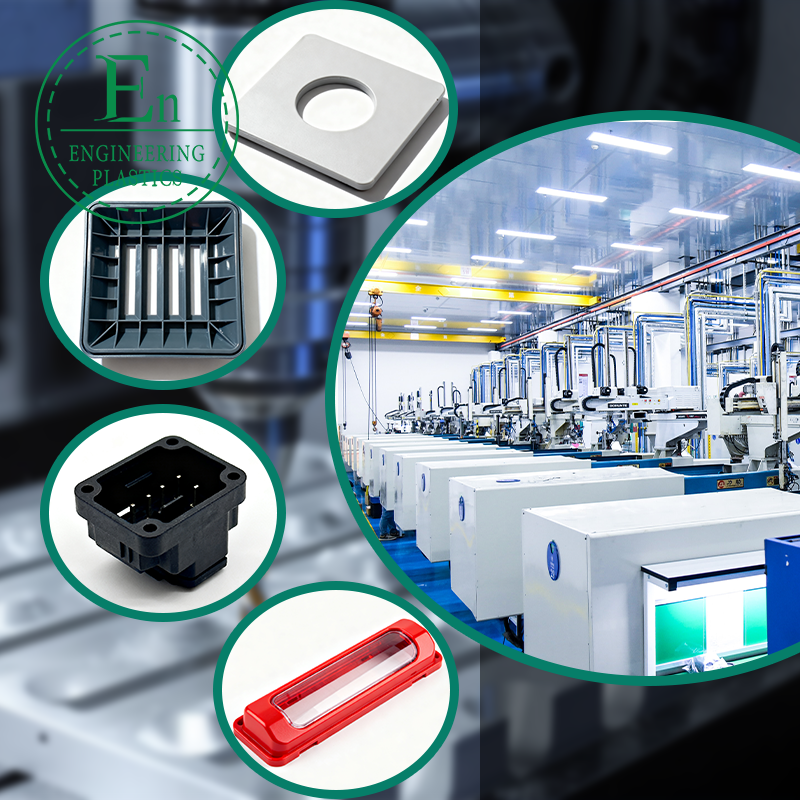

High-Performance ABS Injection Molding for Automotive, Electronics & Industrial Applications

In Europe and the US, ABS (acrylonitrile butadiene styrene) is still one of the most sought-after engineering plastics, particularly for businesses looking to strike a balance between cost effectiveness, durability, and design freedom. Our specialty at Guangdong Engineering Plastics Industries Group Co., Ltd. is inject mold ABS solutions designed for components with high precision, strength, and temperature tolerance. We support international brands in the automotive, electronics, home appliance, industrial, and bespoke OEM/ODM industries with our more than two decades of manufacturing experience.

This article examines how ABS injection molding might help European and American business-to-business (B2B) buyers by resolving common sourcing issues, producing competitive outcomes, and delivering dependable performance. We also go over case studies, production capabilities, and how our engineering team helps clients from concept to completed parts.

Why ABS Injection Molding Remains a Top Choice for Global Manufacturers

The automotive and industrial industries make extensive use of ABS because it offers:

Outstanding stability in dimensions

Moderate resistance to heat

Better impact resistance

Excellent finishing quality and machinabilit

Economical manufacturing in huge quantities

Reliable molding results in intricate geometries

Injection-molded ABS is a popular choice among American and European businesses for parts that need to be durable in real-world applications. Secondary procedures including painting, plating, ultrasonic welding, printing, and assembly are also supported by ABS.

Heat-Resistant ABS for Components at High Temperatures

Inject mold ABS high-temperature components are among the most rapidly expanding consumer needs in the United States and Europe, particularly for electronic housings, HVAC systems, and automobile interiors. These elements frequently call for:

Resistance to heat above 90°C

Dimensional dependability during extended temperature fluctuations

Compatibility with reinforced materials (glass-filled ABS, PC/ABS)

extended lifespan under mechanical strain

In addition to using premium ABS grades from international companies (SABIC, LG Chem, Chimei, etc.), our factory is able to provide modified ABS formulas to satisfy higher thermal stability standards.

Personalized ABS Inject Mould Options for Automakers

Custom ABS inject mold automobile parts are commonly sought after by automotive clients in North America and Europe for:

Trim for interior decoration

Components of a ventilation system

Console and dashboard components

Housings for sensors

Covers for connectors

Supports for structures and brackets

Our engineering staff works directly with car buyers to enhance designs in order to make them more moldable, lighter, and in conformity with IATF 16949-aligned standards.

Common Issues with Automotive Business-to-Business Purchasers (and Our Solutions)

1. Tolerances & Dimensional Accuracy

Strict dimensional tolerances are frequently required by European and American automakers. Our solution is high-precision CNC machining for molds + CMM thorough inspection for completed parts.

2. Regular Color Correspondence

Our solution is an in-house color matching lab with spectrophotometer testing, which is particularly crucial for visible interior components.

3. Qualifications for Material Certification

Buyers want proof of OEM-specific material approvals, RoHS, REACH, or UL 94. Our solution is complete material traceability plus third-party compliance documentation.

4. Mechanical strength and heat resistance

Improved ABS blends for increased stiffness and heat resistance are our answer to the growing demand from OEMs for better ABS materials.

5. Multi-Cavity Molds for Production in Large Volumes

High production efficiency is necessary for automotive suppliers to lower cost per unit. Our approach is the development of multi-cavity molds using flow simulation and cooling channel design optimization.

ABS Injection Molding in Industrial and Electronic Devices

In addition to cars, ABS is frequently utilized for:

Housings for electronic devices

Cases for power tools

Parts of appliances

Housings for mechanical equipment

Office supplies

Smart home appliances

Safety gear

ABS is frequently chosen by industrial and electronics firms in the US and Europe because of its:

Properties of electrical insulation

Resistance to impacts

IMD/IML surface decorating compatibility

Outstanding moldability for intricate shapes

For B2B buyers looking for long-term dependability, we frequently develop ABS parts that must withstand mechanical stress, UV exposure, or climatic changes.

Case Study: American Manufacturer of Smart Appliances

Client Requirement:

For their new generation thermostat device, a North American smart appliance firm needed custom ABS housings with exceptional surface polish, strict tolerances, and flame-retardant qualities.

Challenges:

intricate interior structural ribs

Accurate fit for electronic parts

UL 94 V-0 material specifications

glossy, attractive surface

Warpage and sink mark risk

Our Approach:

Using Moldflow simulation, the mold flow was optimized.

Wall thickness was changed to strike a balance between strength and beauty.

Multi-point gating was designed to remove flow markings.

used ABS that was flame-retardant and consistently shrunk

QC checkpoints were implemented at each stage of production.

Result: With consistent monthly production for more than three years and a 23% project cost reduction over their former supplier, the customer successfully launched the product in both the US and EU markets.

Customization Potential of ABS Mold

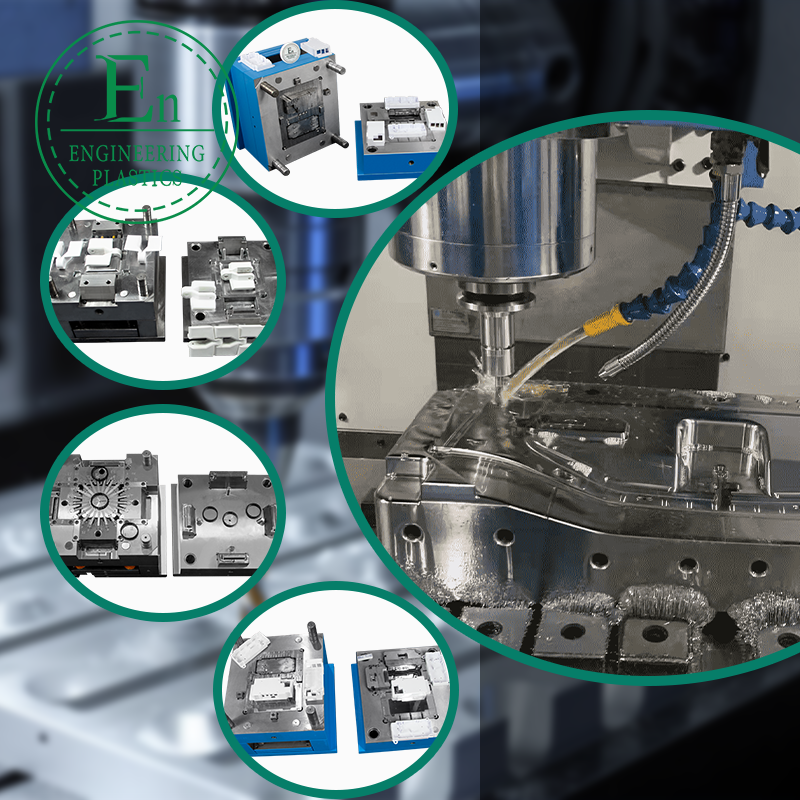

Our mold-making skills at Guangdong Engineering Plastics Industries Group Co., Ltd. include:

• Types of Mold:

Molds with a single cavity

Molds with many cavities

Molds in families

Systems with hot runners

Injection molds with gas assistance

Inserting molding instruments

• Equipment & Machinery:

Centers for CNC machining

EDM wire-cut

EDM at a slow speed

80T to 1600T injection molding machines

Robotic pickers that operate automatically

CMM and three-dimensional measuring devices

• Standard Tolerances:

±0.01-0.05 mm, contingent on resin grade and part design.

• Volume of Production:

Ideal for mass production, low-volume production, and prototyping.

Ensuring Quality in European and American Markets

We adhere to stringent quality control protocols in order to satisfy the demands of upscale clients:

• Inspection of Incoming Materials

Resin grade, certification, and consistency of properties are verified.

The process of mold approval (T0, T1, T2, etc.)

Before mass production, there should be clear testing procedures to guarantee mold performance.

• Quality Control in Process

Each batch was examined for flaws, mechanical strength, size, and color.

• Last-Minute Check and Packaging

For long-distance shipments, use special packaging to avoid distortion or damage.

• Assistance with Compliance

Upon request, regulatory documents such as RoHS, REACH, and UL certification can be obtained.

Common European and American Pain Points. Purchasers (and How We Address Them)

First Pain Point: Barriers to Communication

Our approach is to have English-speaking engineering and sales professionals ready for real-time updates, as many buyers find it difficult to communicate with factories or receive clear engineering support.

Pain Point 2: Unreliable Quality

Our solution: Strict quality tracking system + repeatable QC operations. Some vendors are unable to maintain consistent quality across long-term orders.

Pain Point 3: Production Delays

The supply chain is impacted by lead time disruptions. Our solution consists of backup machinery, visual progress reporting, and standardized mold timeframes.

Pain Point 4: Pricing that is opaque

Unexpected production costs. Our solution: Explicit cost breakdowns for materials, logistics, tooling, and unit pricing.

How We Assist Your ABS Injection Molding Initiative

1. Technical Advice

Design-for-manufacturing (DFM), structural analysis, and material selection.

2. Design and Manufacturing of Molds

Mold manufacture, flow analysis, and 2D/3D design are handled by qualified mold engineers.

3. Production and Optimization of Trials

T0–T3 sampling with engineering advice to improve the design.

4. Manufacturing in Bulk and Assembling

Injection molding that is automated and offers optional assembly services.

5. International Shipping

help for logistics to destinations in the US, Europe, and other countries.

Guangdong Engineering Plastics Industries Group Co., Ltd.: Why Pick It?

More than 20 years of experience with ABS molding

rigorous adherence to global manufacturing standards

Strong QC procedures and contemporary production equipment

Excellent engineering assistance for intricate custom ABS projects

enduring alliances with American and European businesses

Quick sampling, consistent production, and affordable factory prices

We provide reliable quality with complete engineering assistance, whether you need bespoke ABS inject mold automotive parts, inject mold ABS high-temperature components, or inject mold ABS.

Final Thoughts and Call to Action

For businesses requiring dependable, long-lasting, and reasonably priced components—particularly in the automotive, electronics, and industrial sectors—ABS injection molding is an essential manufacturing solution. Our staff is prepared to assist your next project if your company is looking for a long-term partner that can provide high-quality, designed ABS parts that meet stringent international standards.

Take Action – Collaborate With a Reputable ABS Injection Molding Producer

Get in touch with us to discuss your project, get technical advice, or obtain a quote.

Guangdong Engineering Plastics Industries Group Co., Ltd.

Email: sales@gz-plastics.com

Website: https://gzplastics.com/