Custom Online

3D Printing Services

On-demand 3D printing for rapid prototyping and production in as fast as 3 days. Get an instant quote today.

- ISO 9001: 2015 Certified Quality

- Tolerances as fine as ±0.2 mm.

- Global Delivery in as Fast as 3 Days

Start A New Injection Molding Quote

Our 3D Printing Services

EnQi offers a comprehensive suite of high-quality additive manufacturing solutions, encompassing technologies like FDM, SLA, SLS, and SLM. This enables the production of both plastic and metal parts, supporting applications from functional prototyping to end-use part production.

3D printing is ideal for creating one-off parts, small batches, and complex geometries that are difficult or impossible to achieve with traditional manufacturing methods.

Why Choose EnQi?

At EnQi,We provide high-quality, dependable 3D printing solutions that accelerate your rapid prototyping and production.

Comprehensive 3D Printing Technologies

We provide a full range of industrial 3D printing processes—including FDM, SLA, SLS, and DMLS—enabling you to select the optimal technology based on material needs, surface quality, mechanical properties, and application requirements.

Rapid Parts Delivery

Leveraging our streamlined workflow and in-house production capabilities, we deliver custom 3D-printed parts in as little as 72 hours, helping you speed up product development and shorten lead times.

From Prototyping to Low-Volume Production

Whether you're validating a design concept or scaling to low-volume manufacturing, we efficiently convert your 3D models into high-quality plastic, metal, and elastomeric parts.

Dedicated Engineering Support

Our experienced engineering team supports you through every phase—from 3D model optimization and DFAM to material recommendation and tolerance analysis—collaborating closely to ensure your parts meet performance and budget goals.

Start Your Custom 3D Printing Project Today.

All information and uploads are secure and confidential.

3D Printing Technologies

EnQi offers high-quality additive manufacturing services, including FDM, SLA, SLS, and SLM, enabling fast, precise 3D printing in plastics and metals. Ideal for rapid prototyping, functional parts, and low-volume production, our solutions handle complex geometries that traditional methods can’t achieve

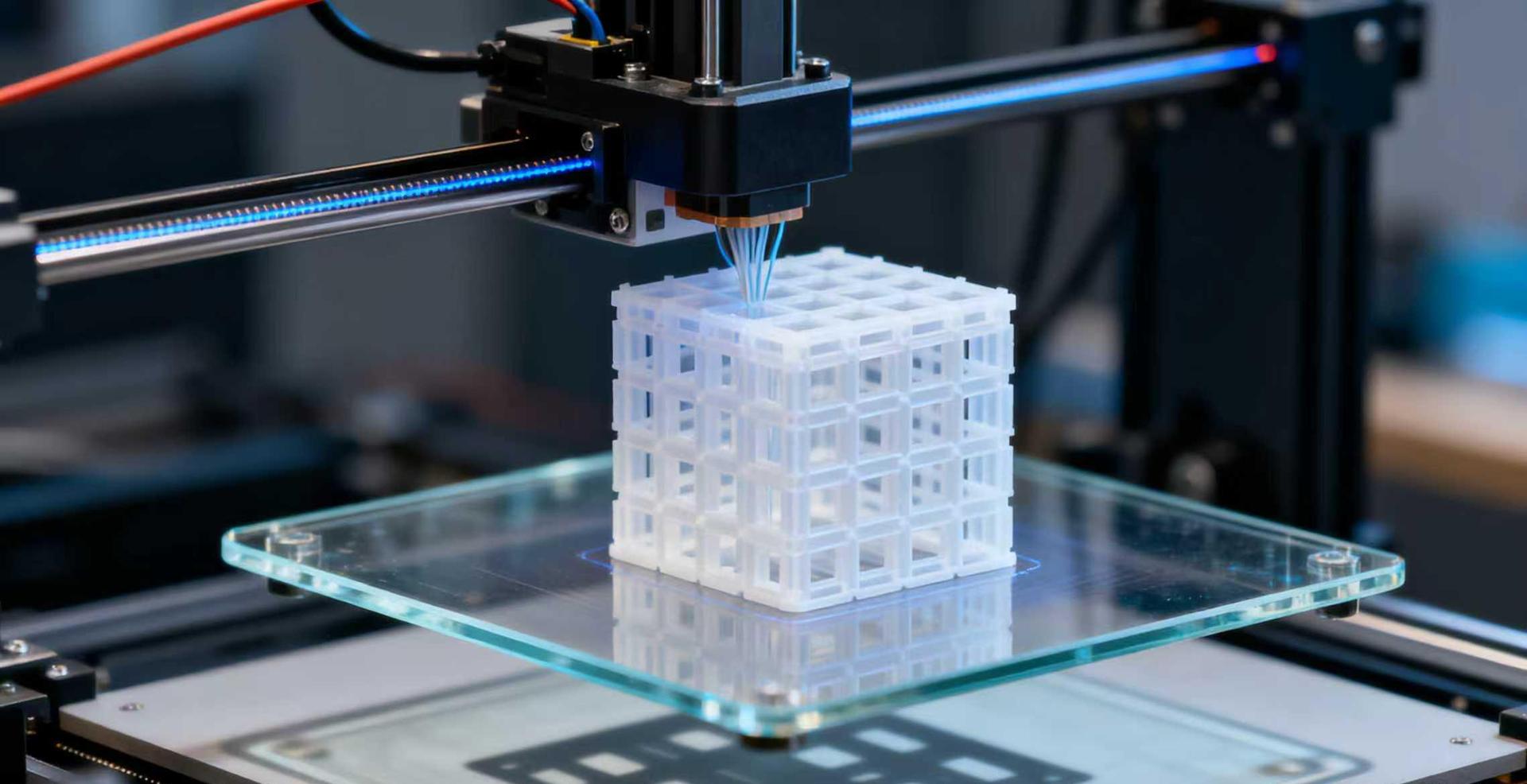

1. FUSED DEPOSITION MODELING (FDM)

Affordable for basic prototypes

Fused Deposition Modeling (FDM), also called Fused Filament Fabrication (FFF), is a leading additive manufacturing technique known for its accessibility and versatility. It constructs parts by selectively depositing layers of molten thermoplastic, guided by a computer-controlled nozzle.

The process begins with a solid filament spool. The filament is fed to an extruder, where it is melted and laid down with precision along a pre-programmed path. Each deposited layer fuses to the one below upon cooling, allowing for the creation of complex geometries with minimal waste.

This makes FDM ideal for prototyping, custom parts, and educational applications.

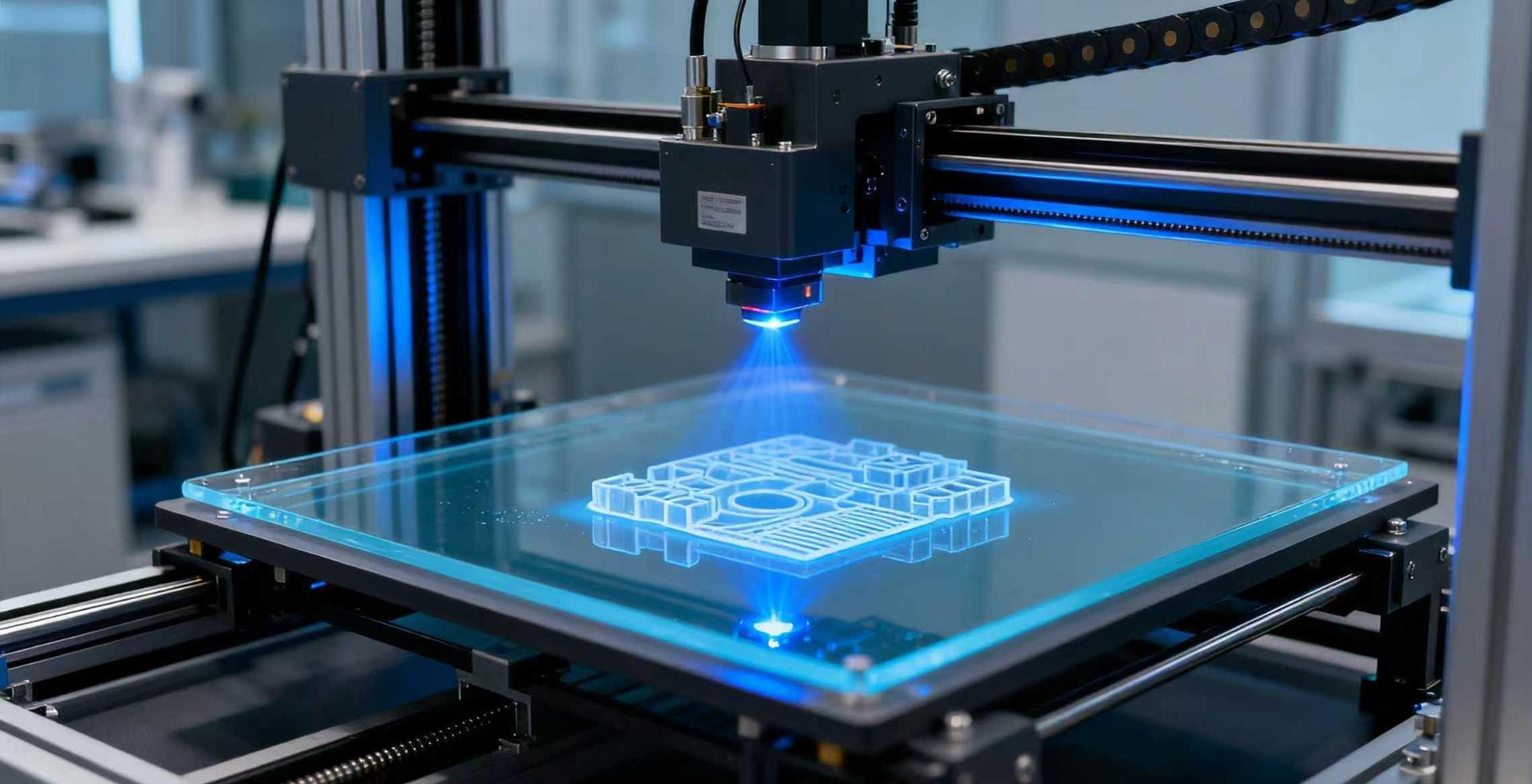

2. STEREOLITHOGRAPHY (SLA)

Visual prototype

Stereolithography (SLA) is a pioneering additive manufacturing technology that uses a laser to cure liquid resin into solid parts, differing significantly from filament-based FDM. It is renowned for producing parts with the highest resolution and smoothest surface finish among common 3D printing processes.

During printing, a laser beam is guided across a vat of liquid photopolymer resin by a dynamic mirror system, curing precise cross-sections layer by layer. The build platform adjusts its height after each layer is completed.

While its material selection is confined to photopolymers, SLA is unparalleled for applications demanding extreme detail and smoothness, such as prototypes, jewelry, and dental models. As one of the first 3D printing methods developed, it remains a cornerstone of professional additive manufacturing.

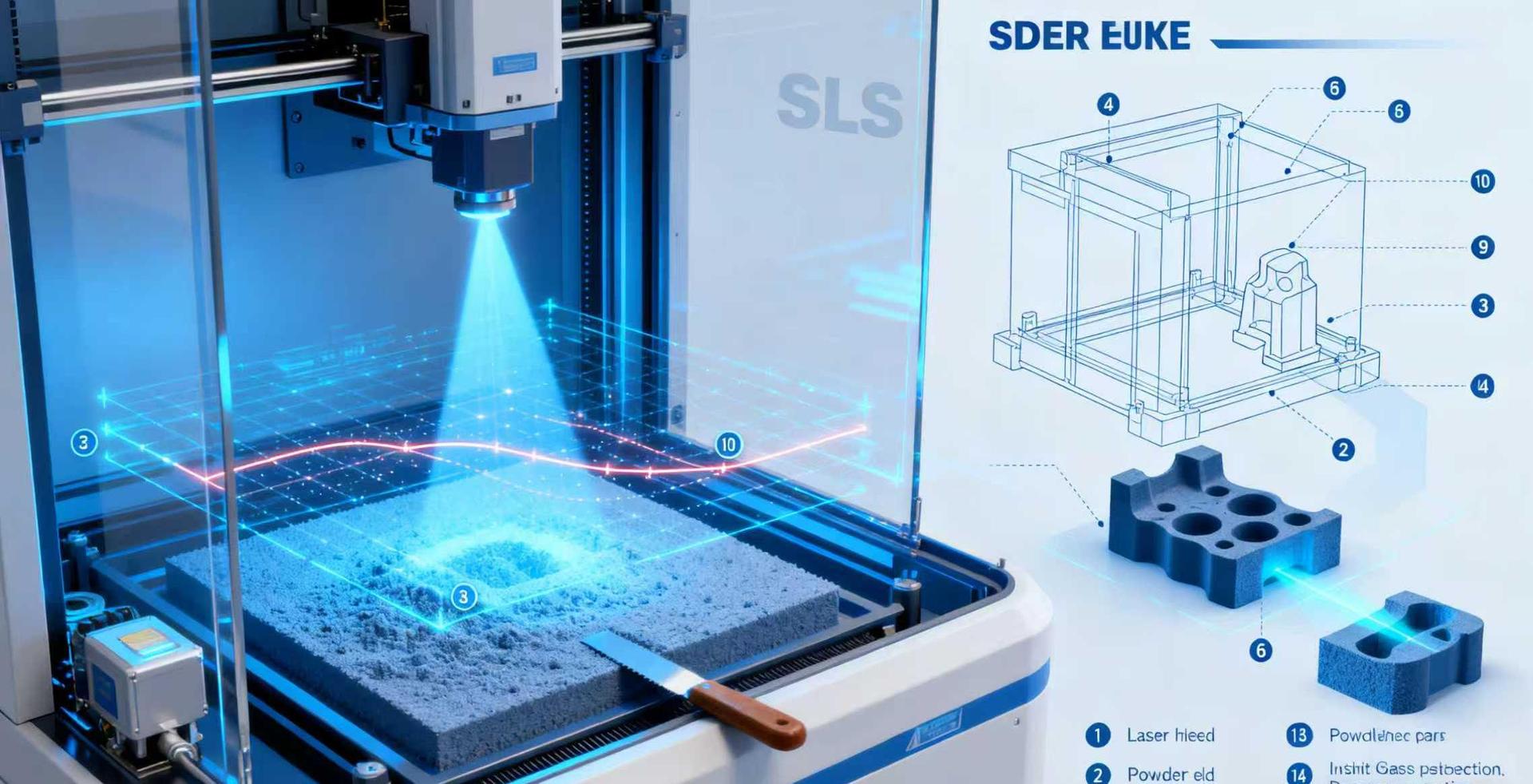

3. SELECTIVE LASER SINTERING (SLS)

Functional prototyping and low-volume parts

Selective Laser Sintering (SLS) is a powder bed additive manufacturing process used to make parts from thermoplastic polymer powders. It is commonly used for functional parts, since SLS printed components have good mechanical properties.

An SLS 3D printer works by sintering areas of plastic powder with a laser. During the process, a thin layer of powder is distributed evenly across the build platform, after which the laser sinters selected areas of the 2D layer. When the layer is complete, the platform is lowered, more powder is added, and the laser sinters the next layer.

When all layers are complete, the part is left to cool. Unused powder is kept to be used again, and the part is cleaned to remove excess material.

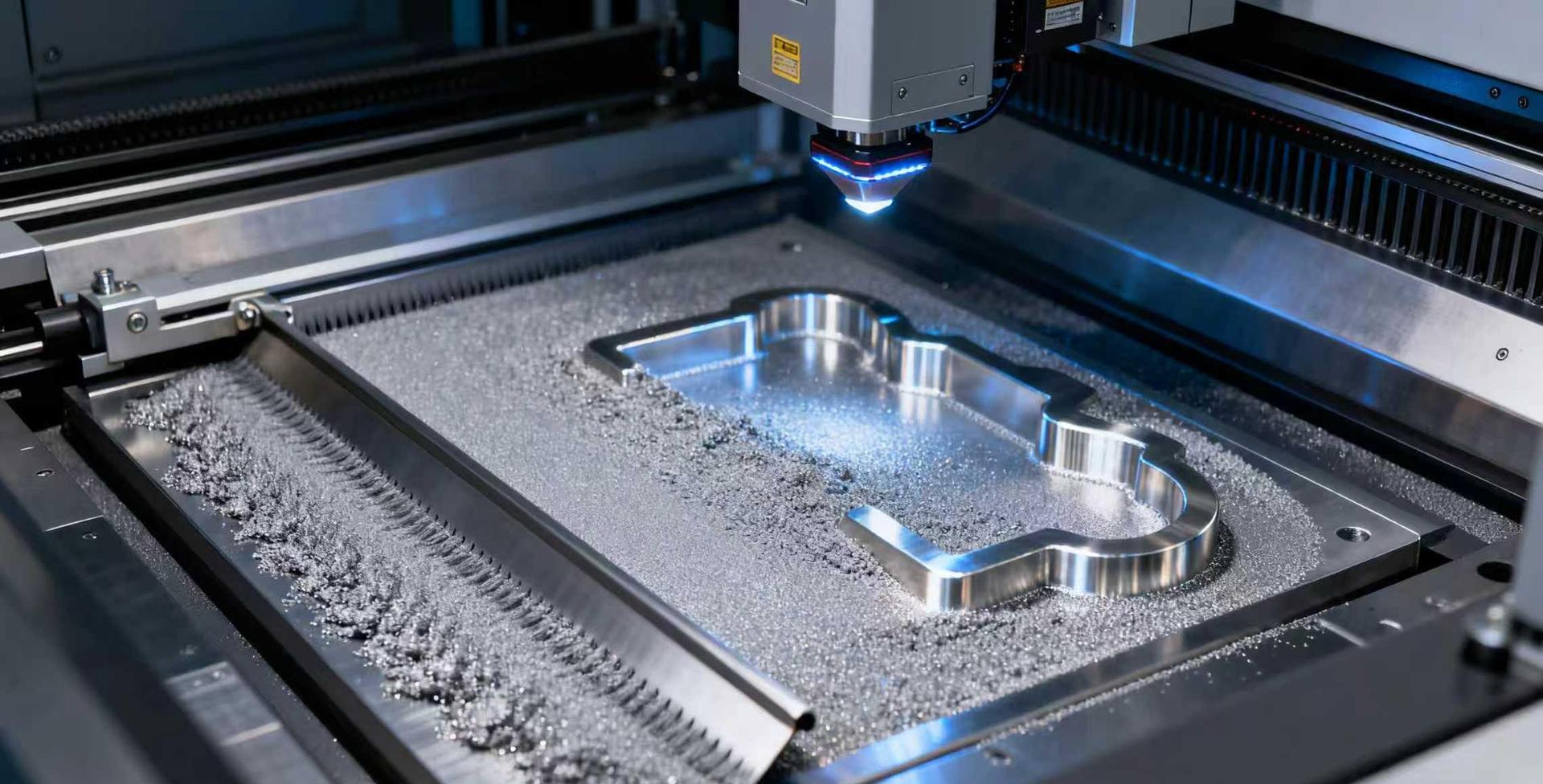

4. SELECTIVE LASER MELTING (SLM)

Parts for functional end use

Selective Laser Melting (SLM) is a metal 3D printing process that builds high-strength parts layer by layer from fine metal powder. Inside a sealed, inert gas-filled chamber, a powerful laser selectively melts the powder based on the cross-sections of a CAD model.

Once a layer is completed, the build platform lowers slightly, and a fresh layer of powder is spread across the surface to continue the build. Unlike sintering processes, SLM fully melts the metal powder, resulting in parts with excellent mechanical properties and near-wrought strength.

This makes it suitable for highly demanding applications in aerospace, automotive, medical, and more. The technology also allows for the production of complex geometries, internal channels, and lightweight structures that are difficult or impossible to achieve with traditional manufacturing.

Looking for more additive manufacturing solutions?

Contact Us3D Printing Technologies Compared: Which One is Right for You?

When selecting a 3D printing technology, begin by defining your key design requirements and the intended end use of the part. This will help determine the most suitable printing method for your application. Refer to the table below for a comparison of available technologies.

| Technologies | FDM | SLA | SLS | SLM |

|---|---|---|---|---|

✓Advantages |

|

|

|

|

✓Disadvantages |

|

|

|

|

✓Typical layer height | 50-400 microns | 25-100 microns | 100-120 microns | 20-50 microns |

FDM

Advantages

- •Most affordable 3D printing process for plastic parts

Disadvantages

- •Relatively Low Surface Quality.

- •Visible layer lines, weaker layer bonding.

- •Not cost-effective for high volumes

Typical layer height

50-400 microns

SLA

Advantages

- •High resolution

- •No visible layer lines, smooth finish

- •Ideal for transparent parts

Disadvantages

- •Printers more expensive than FDM

- •Weak parts will degrade with sunlight

- •Extensive post-processing required

Typical layer height

25-100 microns

SLS

Advantages

- •Consistent strength

- •No support structures needed

Disadvantages

- •Porosity

- •Rough surface finish

- •High cost

Typical layer height

100-120 microns

SLM

Advantages

- •Strong and hard parts

- •Ideal for complex shapes

Disadvantages

- •Limited build size

- •Thermal stress and warping

- •High cost

Typical layer height

20-50 microns

precision.materials.title

PEEK

precision.materials.items.PEEK.desc

质量控制

在恩奇制造,质量是我们的重中之重。我们贯穿整个生产流程实施严格的质量控制措施,确保每个零件都达到最高的精度和可靠性标准。我们完善的质量保证体系包含先进的检测工具和技术,以保持产品的一致性和卓越品质。

过程检验

我们的质量控制始于过程检验,在生产的各个阶段对每个零件进行检查,以确保其符合设计规范。这种积极主动的方法有助于在制造过程早期发现并纠正任何问题。

最终检查

所有零件在出厂前均需经过严格的最终检验,以确保其质量和精度。我们采用先进的测量工具和技术,确保每个零件都符合所需的规格和标准。

精密测量工具

我们采用一系列精密测量工具,包括坐标测量机 (CMM)、光学比较仪和激光扫描仪,来精确测量数控加工零件的尺寸和公差。这些工具使我们能够保证所生产的每个零件都具有严格的公差和高精度。

ISO 9001、ISO 14001、IATF 16949 和 AS9100D 认证

我们对质量的承诺体现在我们获得的 ISO 9001、ISO 14001、IATF 16949 和 AS9100D 认证上。这些国际标准确保我们的质量管理体系高效且持续改进,从而为客户提供始终如一的高品质产品。

持续改进

我们秉持持续改进的理念,定期审查流程和实践,以发现需要改进的领域。通过投资最新技术和员工培训,我们力求保持我们在质量和创新方面的良好声誉。

客户评价

深受创新型公司信赖

行业应用

需要帮助? 我们随时为您服务。

如果您有任何疑问或需要帮助,我们的团队随时准备为您提供支持。 全天候 24/7 服务。您可以通过以下任何方式联系我们。