CNC Turning with EnQi

EnQi CNC turning process produces metal and plastic turned parts in days. We are an ISO 9001:2015 certified manufacturer offering high-quality custom CNC turning services to clients worldwide. With over 20 years of experience, our CNC turning capabilities allow us to deliver turned parts with consistent quality.

As a leading turned part supplier, we support custom projects from prototypes to full-scale production. Our precision CNC turning lathes are capable of producing both simple and complex cylindrical geometries with tight tolerances. Our CNC lathes with live tooling can machine features like axial/radial holes, grooves, slots, and flats, with high repeatability, even for tight-tolerance geometries.

Whether you're a startup launching a first product or a global manufacturer needing a reliable partner, EnQi delivers expert engineering, fast turnaround, and competitive pricing for your CNC turning projects.

Why Choose EnQi?

Advanced CNC Turning Capabilities

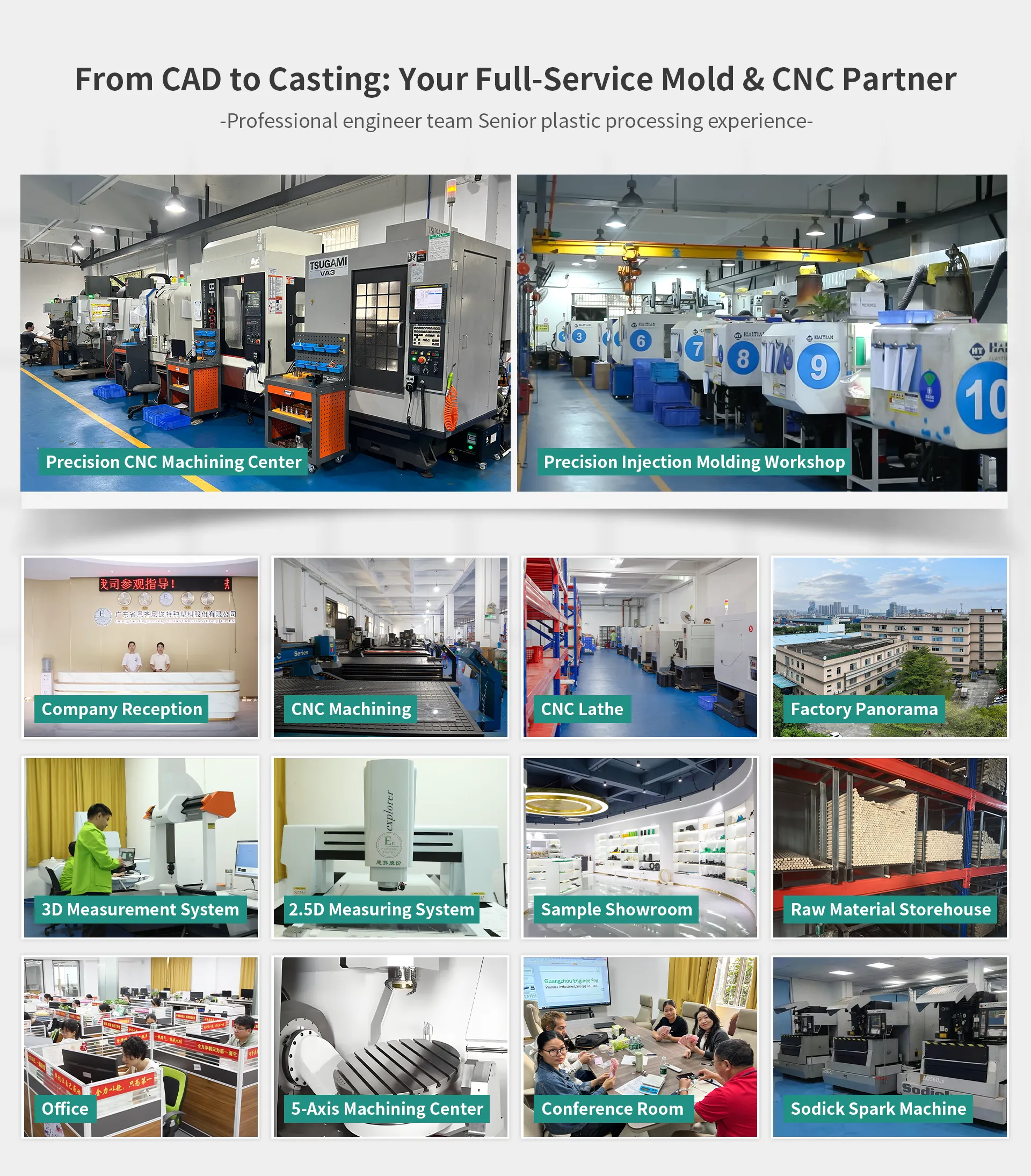

EnQi operates two CNC machining facilities, equipped with over 60 machines, including advanced multi-axis CNC lathes. Custom turned parts can be manufactured in as little as 5 days, helping you avoid production delays and stay ahead of schedule.

End-to-End CNC Turning Solutions

From functional prototypes to low-volume production, we bridge the gap between design and delivery. Our integrated CNC turning manufacturing systems accelerate product development while maintaining tight tolerances and consistent part quality across every production stage.

Experienced CNC Engineers

Our expert team specializes in CNC turning services with deep knowledge of DFM validation, material selection, and achieving complex geometries. We support you through every phase—from drawing and part analysis to precision CNC turning—ensuring smooth communication.

Mastering Complex CNC Turning Projects

Our CNC lathes can produce complex cylindrical components such as stepped shafts, bushings, collars, housings, and other custom-designed round parts. We machine both metals and engineering plastics, delivering high dimensional accuracy, fine surface finishes, and excellent concentricity.

CNC Turning Materials

Our CNC turning services support a wide range of metals and engineering plastics. Whether you need precision turning of plastic parts or other materials, we can deliver precise parts or industries such as automotive, aerospace, and medical devices. If your project requires a specific material, feel free to contact us- -our team will evaluate your requirements and recommend the best solution.

PEEK

precision.materials.items.PEEK.desc

CNC Turning Tolerances

We deliver CNC turned parts with both standard (±0.1mm) and tight tolerances (±0.005mm), balancing cost efficiency with high precision. Whether for general applications or advanced products, our CNC turning services guarantee every component meets your exact specifications.

Feature

Description

Maximum Part Size

4000×1500×600 mm

Distance Dimensions

For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005"

Orientation and Form Dimensions

0-12" +/- 0.005", Angularity 1/2 degree. For 24" and beyond please consult EnQi's Manufacturing Standards.

Precision Tolerances

EnQi can manufacture and inspect to tight tolerances, including sub +/- 0.001" tolerances, per your drawing specifications and GD&T callouts.

Minimum Feature Size

5 x 5 x 5 mm

Threads and Tapped Holes

EnQi can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review.

Surface Finish

The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote.

Edge Condition

Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print.

质量控制

在恩奇制造,质量是我们的重中之重。我们贯穿整个生产流程实施严格的质量控制措施,确保每个零件都达到最高的精度和可靠性标准。我们完善的质量保证体系包含先进的检测工具和技术,以保持产品的一致性和卓越品质。

过程检验

我们的质量控制始于过程检验,在生产的各个阶段对每个零件进行检查,以确保其符合设计规范。这种积极主动的方法有助于在制造过程早期发现并纠正任何问题。

最终检查

所有零件在出厂前均需经过严格的最终检验,以确保其质量和精度。我们采用先进的测量工具和技术,确保每个零件都符合所需的规格和标准。

精密测量工具

我们采用一系列精密测量工具,包括坐标测量机 (CMM)、光学比较仪和激光扫描仪,来精确测量数控加工零件的尺寸和公差。这些工具使我们能够保证所生产的每个零件都具有严格的公差和高精度。

ISO 9001、ISO 14001、IATF 16949 和 AS9100D 认证

我们对质量的承诺体现在我们获得的 ISO 9001、ISO 14001、IATF 16949 和 AS9100D 认证上。这些国际标准确保我们的质量管理体系高效且持续改进,从而为客户提供始终如一的高品质产品。

持续改进

我们秉持持续改进的理念,定期审查流程和实践,以发现需要改进的领域。通过投资最新技术和员工培训,我们力求保持我们在质量和创新方面的良好声誉。

客户评价

深受创新型公司信赖

行业应用

需要帮助? 我们随时为您服务。

如果您有任何疑问或需要帮助,我们的团队随时准备为您提供支持。 全天候 24/7 服务。您可以通过以下任何方式联系我们。