Understanding the True Cost: Beyond the 3d Printer Price Tag

When exploring options, the initial 3d printer price is often the most appealing factor, with many consumer-grade models available for just a few hundred dollars. While tempting, this upfront cost rarely tells the whole story. For professional or industrial applications, relying on a hobbyist machine can lead to significant hidden expenses. These include the cost of failed prints due to machine inaccuracies, limitations in material choice which result in parts that lack the necessary strength or heat resistance, and the steep learning curve required to achieve consistent, high-quality results. The true cost includes wasted time, wasted material, and a final product that may not meet engineering specifications. For critical components, a low initial price can lead to a costly failure down the line.

The Professional Advantage: Leveraging a 3d Printer Service

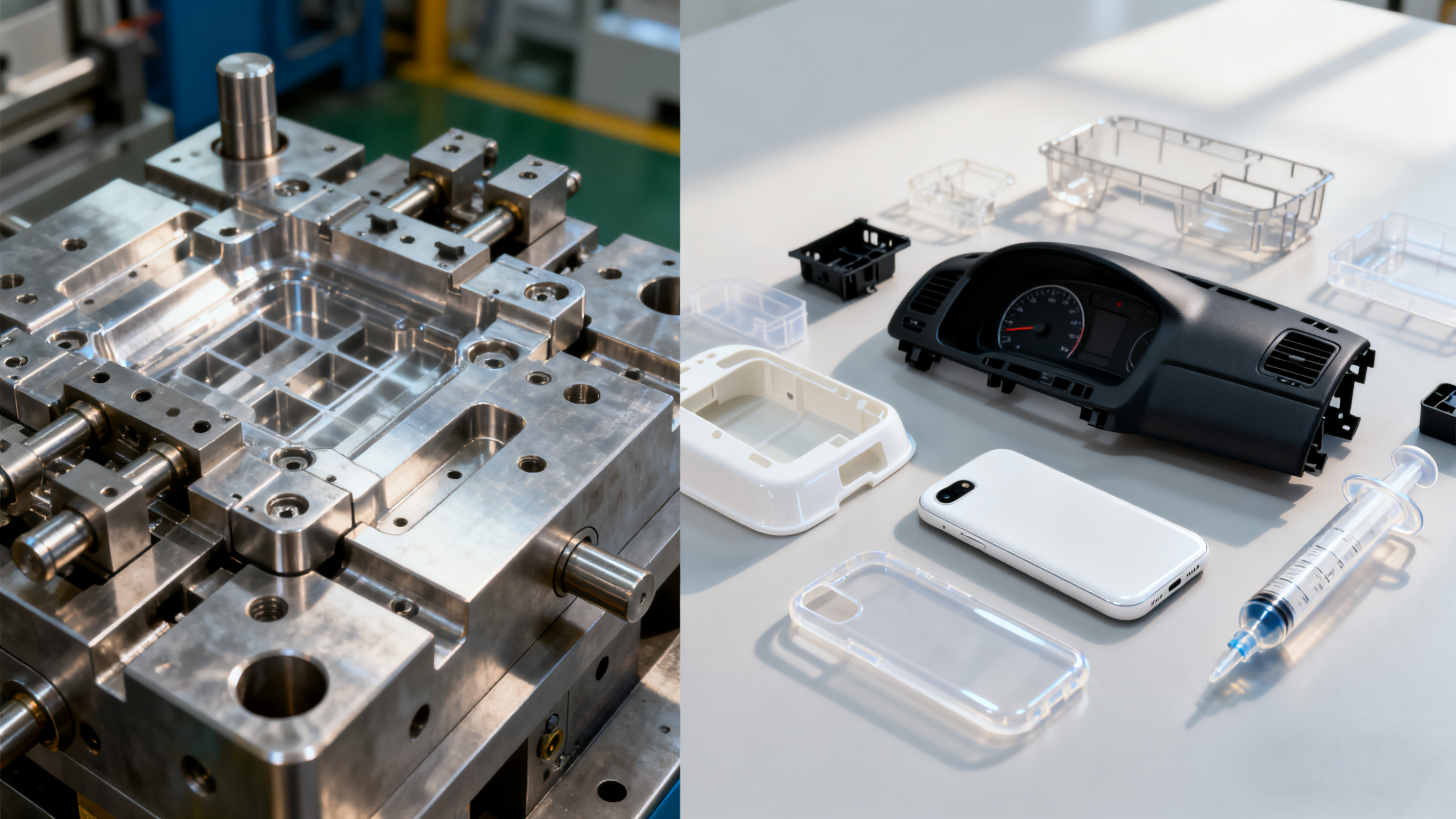

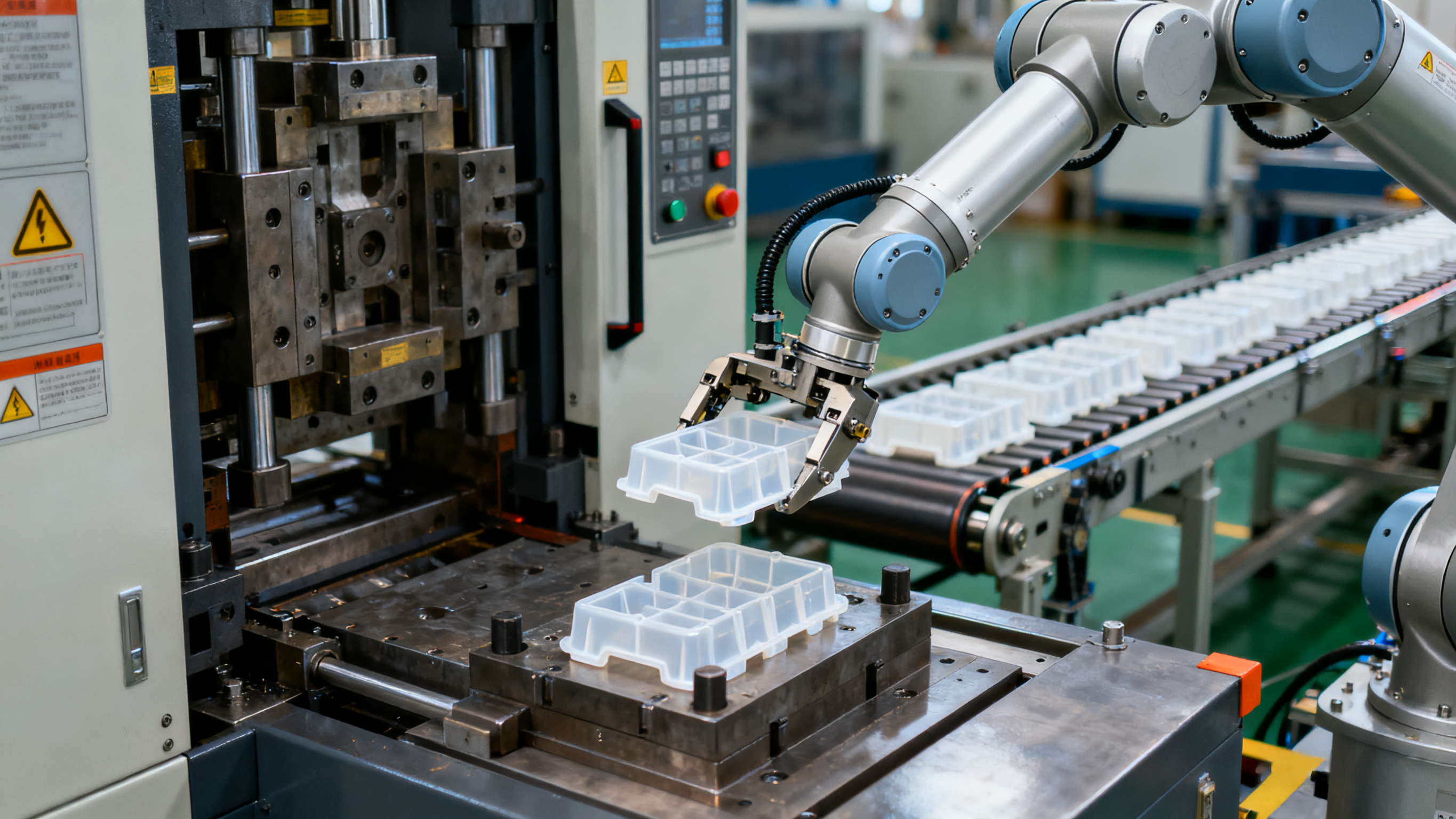

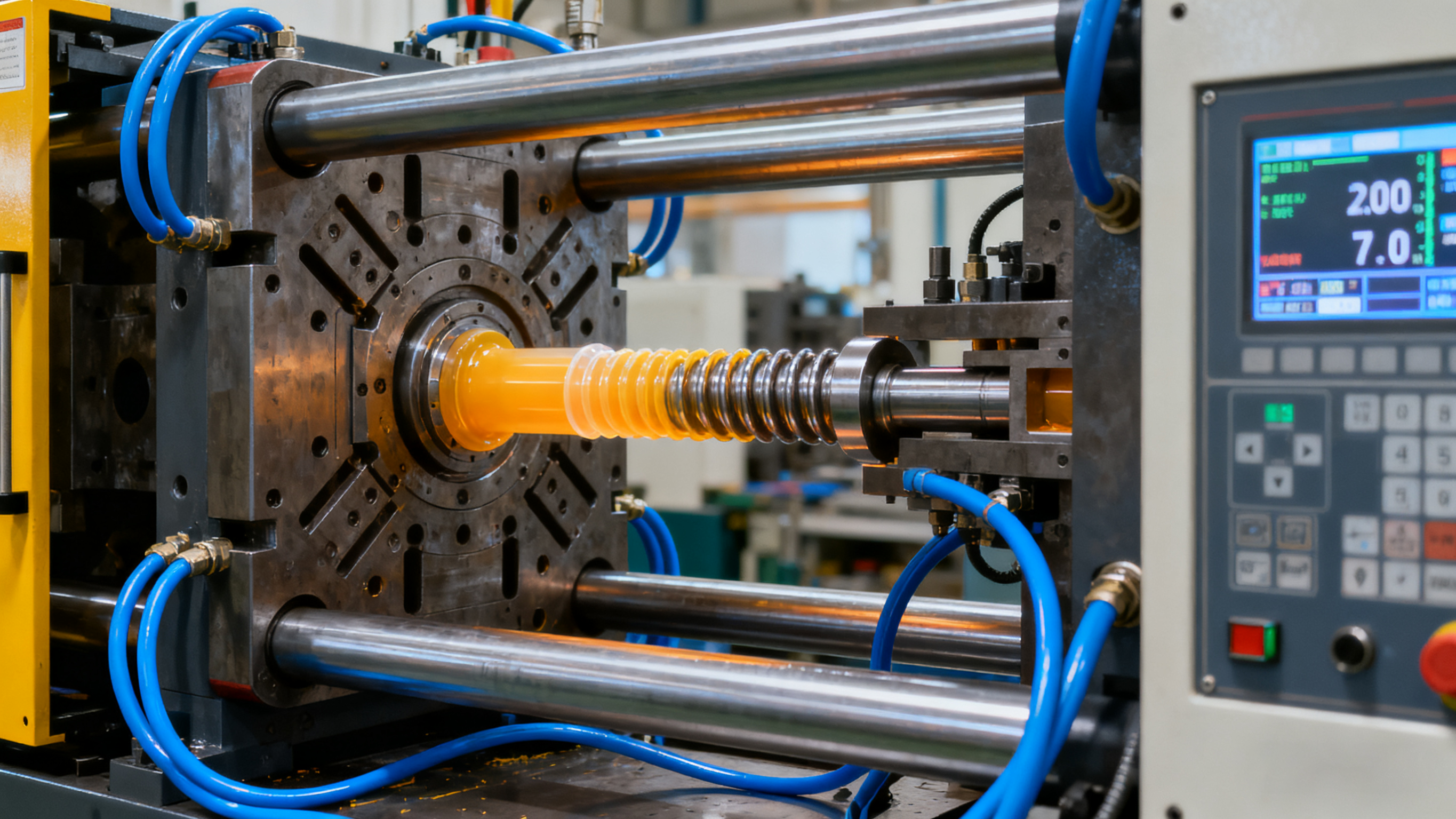

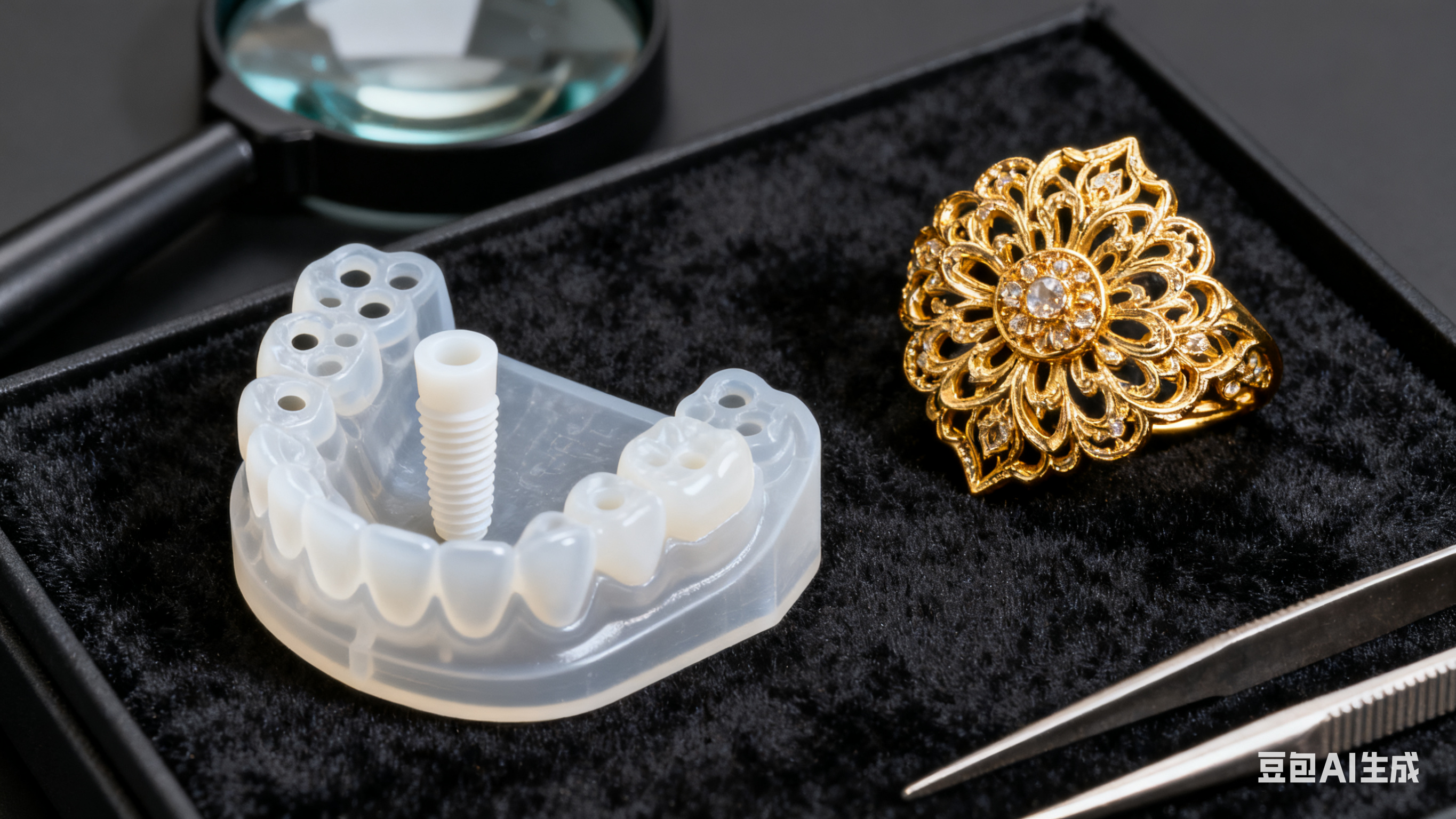

This is where a professional 3d printer service becomes an invaluable asset. Instead of investing in hardware that may not suit your needs, you gain access to industrial-grade machines and a team of experts dedicated to realizing your vision. Imagine partnering with senior engineers who have 15-25 years of experience in material science and component design. A specialized service eliminates the guesswork. It provides access to a vast library of high-performance engineering plastics like PEEK, PPS, and Nylon, ensuring your part has the exact properties it requires, whether it's for a high-wear gear or a chemically resistant sealing ring. This approach guarantees quality, precision, and performance that a desktop machine simply cannot match.

From Concept to Reality: The Importance of Material Expertise

Ultimately, the material is the core of any functional part. The capabilities of a 3d printer are only as good as the plastics it can process. A standard part printed in ABS might be fine for a visual prototype, but it won’t suffice for a high-stress industrial bearing or a pulley in a demanding mechanical system. Our expertise lies in understanding these nuances. We don’t just print; we engineer solutions. By leveraging advanced materials like PEEK for its exceptional mechanical and thermal properties or PTFE for its low friction, we create parts that are not just models, but fully functional, durable components ready for real-world application. This deep knowledge of engineering plastics is what separates a simple print from a reliable, long-lasting industrial part.

Partner with the Experts for Your Next Project

While the low 3d printer price of consumer models has opened the door to innovation, serious projects demand a serious approach. To move beyond basic prototyping and create robust, reliable parts, you need the right combination of advanced machinery, superior materials, and engineering expertise. At Guangdong Engineering Plastics Industries Group Co., Ltd., we provide just that. Our global reputation is built on delivering customized, high-performance plastic components for clients in the USA, UK, Germany, and beyond. Instead of gambling on a consumer device, partner with a team that guarantees precision, durability, and unparalleled material knowledge for your next project.