In the competitive world of manufacturing, a quality controlled plastics supplier plays a crucial role in ensuring that products meet the highest standards of reliability and performance. This is especially important in industries where precision and durability are paramount, such as automotive, aerospace, and electronics. Companies rely on suppliers like Guangdong Engineering Plastics Industries Group Co., Ltd. to deliver materials and components that undergo rigorous quality checks, helping to prevent defects and enhance overall product longevity. By focusing on advanced techniques and materials, these suppliers support innovation and efficiency in global supply chains.

Understanding Quality Control Processes in Plastics Manufacturing

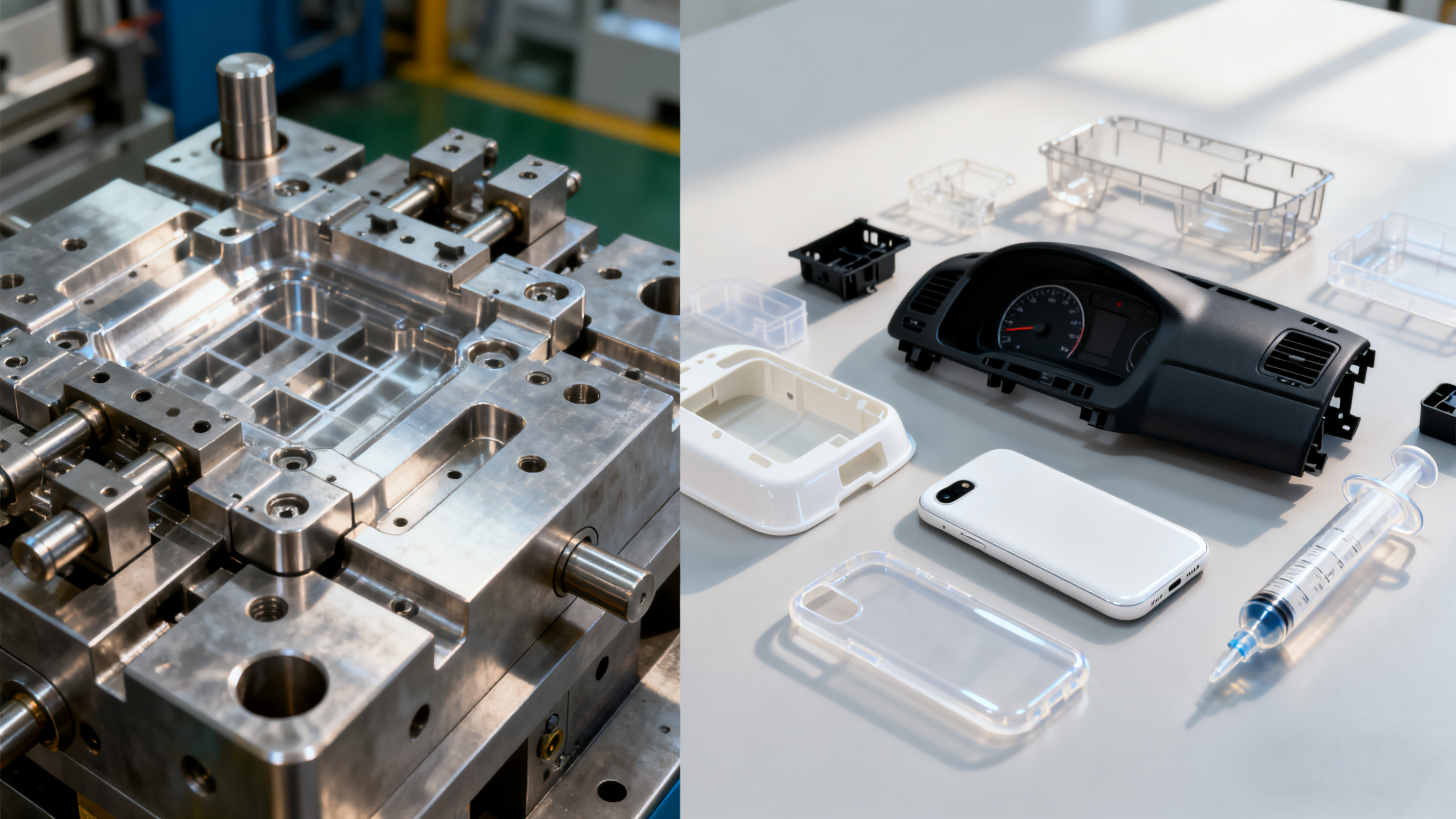

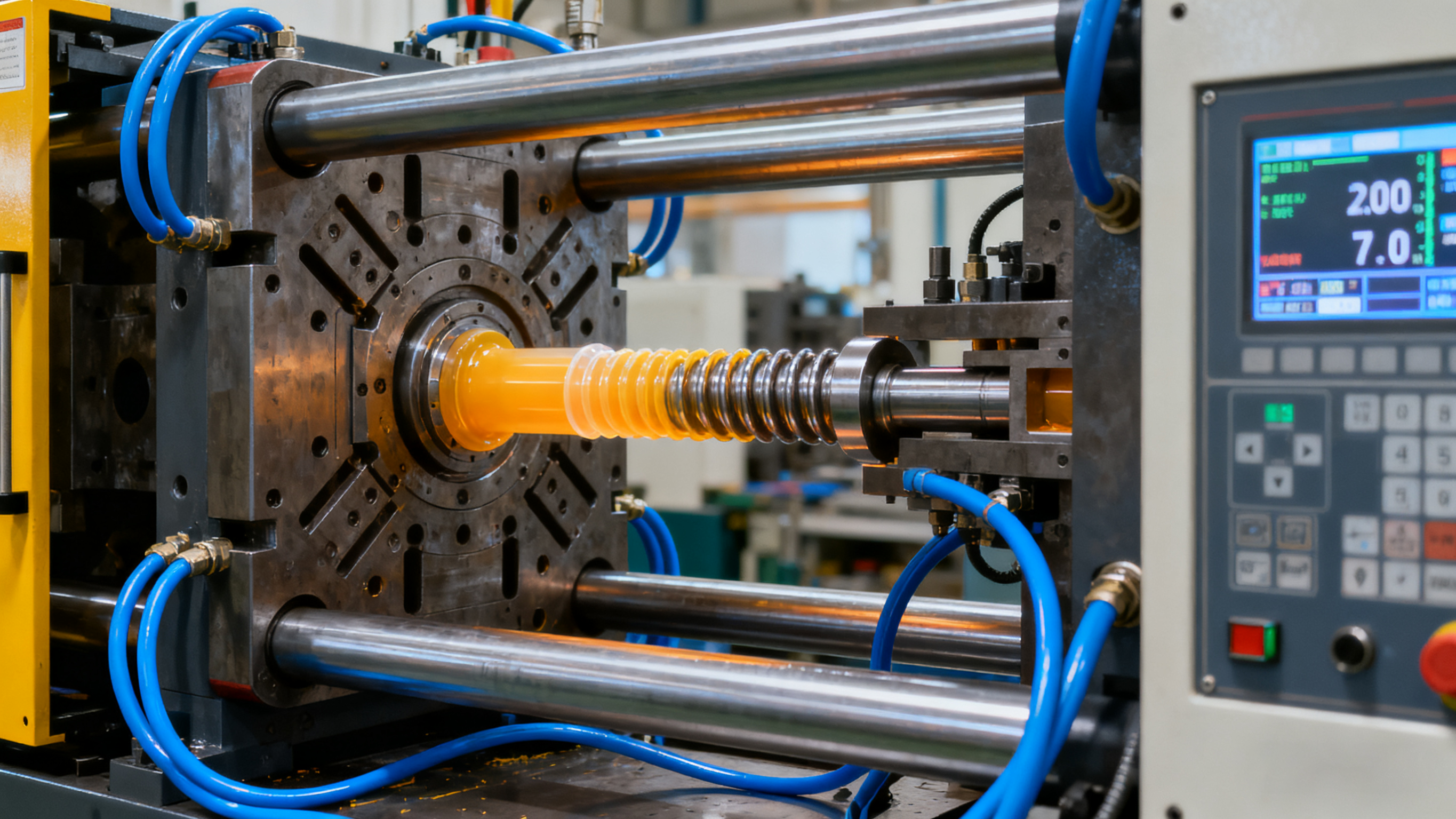

Quality control in plastics manufacturing involves a series of meticulous steps to ensure that every product adheres to strict specifications. At Guangdong Engineering Plastics Industries Group Co., Ltd., our team of senior engineers, each with 15-25 years of expertise, oversees the entire production process from design to delivery. We employ state-of-the-art testing methods, including dimensional analysis, material strength evaluations, and thermal resistance tests, to verify the integrity of our plastics. For instance, when producing engineered plastic components factory items like gears and pulleys, we use high-performance materials such as PEEK and PPS, which are known for their exceptional resistance to wear and chemicals. This level of control not only minimizes waste but also guarantees that our products perform reliably in demanding environments, making us a trusted quality controlled plastics supplier for clients worldwide.

Materials and Customization for Engineered Plastic Components

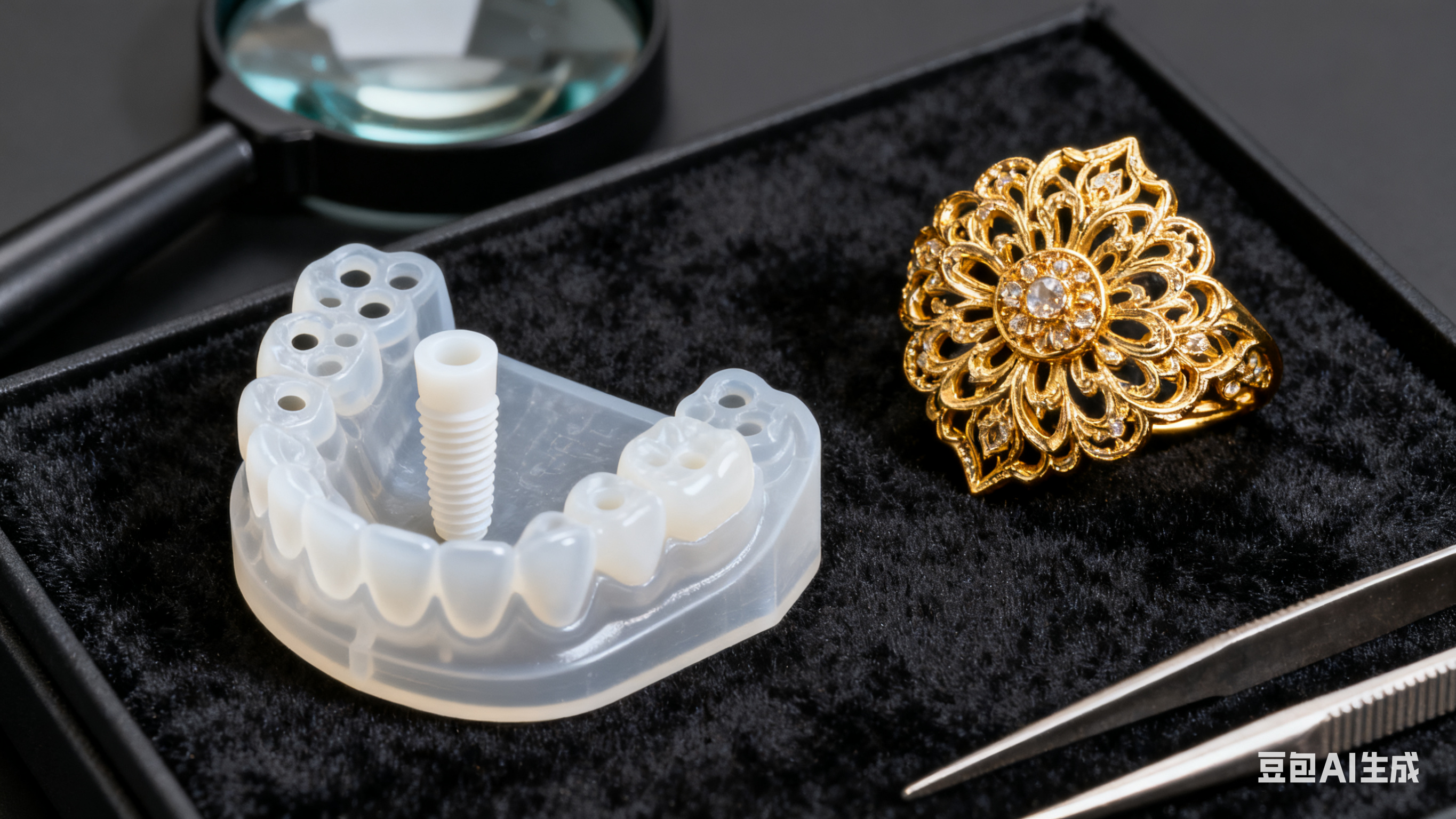

Engineered plastic components factory operations demand a deep understanding of various polymers to create bespoke solutions. At our facility, we specialize in materials like Nylon, ABS, and PTFE, each selected for their unique properties that cater to specific applications. For example, PTFE is ideal for sealing rings due to its low friction and high-temperature tolerance, while PEEK is perfect for bearings in high-stress scenarios. Our reliable plastic manufacturer China approach includes personalized customization, where clients can collaborate with our R&D team to tailor components to exact specifications. This might involve adjusting material blends or designing prototypes that undergo iterative testing. By integrating advanced CAD software and 3D printing for rapid prototyping, we ensure that every batch maintains consistent quality, reducing the risk of failures in the field. As a quality controlled plastics supplier, we pride ourselves on this technical prowess, which has helped us build strong relationships with international clients in the USA, UK, and Germany.

The Role of a Reliable Plastic Manufacturer in Global Markets

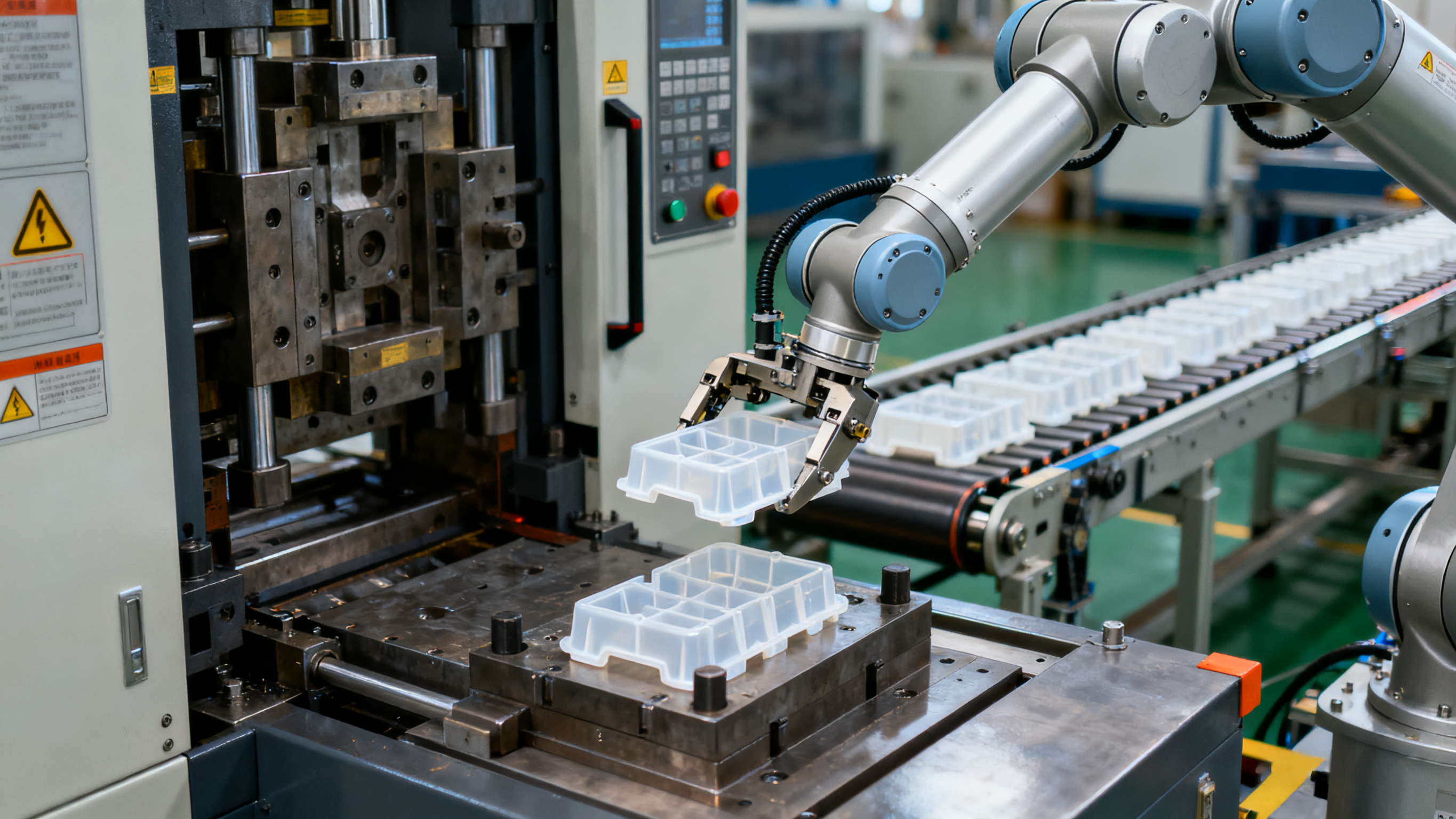

A reliable plastic manufacturer China like Guangdong Engineering Plastics Industries Group Co., Ltd. must navigate complex global standards to maintain its reputation. We export a wide range of products, including sealing rings and bearings, to over 50 countries, adhering to certifications such as ISO 9001 for quality management. Our processes incorporate automated quality checks, such as spectroscopy for material composition and fatigue testing for longevity, ensuring that engineered plastic components factory outputs meet or exceed industry benchmarks. For instance, our gears are designed with precision machining to handle high torque without deformation, a critical factor in automotive applications. As a quality controlled plastics supplier, we also focus on sustainability, using recyclable materials where possible to align with environmental regulations. This commitment to excellence has earned us a loyal customer base, demonstrating how technical expertise translates to real-world value. By continually investing in employee training and facility upgrades, we stay at the forefront of innovation, supporting our clients' growth and success in a rapidly evolving market.

Future Trends and Innovations in Plastics Supply

Looking ahead, the role of a reliable plastic manufacturer China is evolving with advancements in technology, such as additive manufacturing and smart materials. At Guangdong Engineering Plastics Industries Group Co., Ltd., we are exploring these trends to enhance our offerings as a quality controlled plastics supplier. For example, integrating IoT sensors into production lines allows for real-time monitoring of quality metrics, further reducing defects in engineered plastic components factory items. This proactive approach not only improves efficiency but also fosters stronger partnerships with our global clientele. As we continue to expand our capabilities, we remain dedicated to providing comprehensive solutions that drive industry progress.