Bringing a new product from concept to reality is a journey filled with challenges, especially when it involves precision-engineered plastic components. Companies often struggle to find a reliable plastic prototyping manufacturer who not only understands their vision but also possesses the technical prowess to execute it flawlessly. The risks are significant: poor material selection can lead to product failure, design flaws can inflate production costs, and a disconnect between the prototyping and manufacturing stages can cause costly delays. This critical initial phase demands a partner with deep expertise to navigate complexities and transform an idea into a tangible, market-ready product.

Why Expertise is Crucial for Plastic Product Customization China

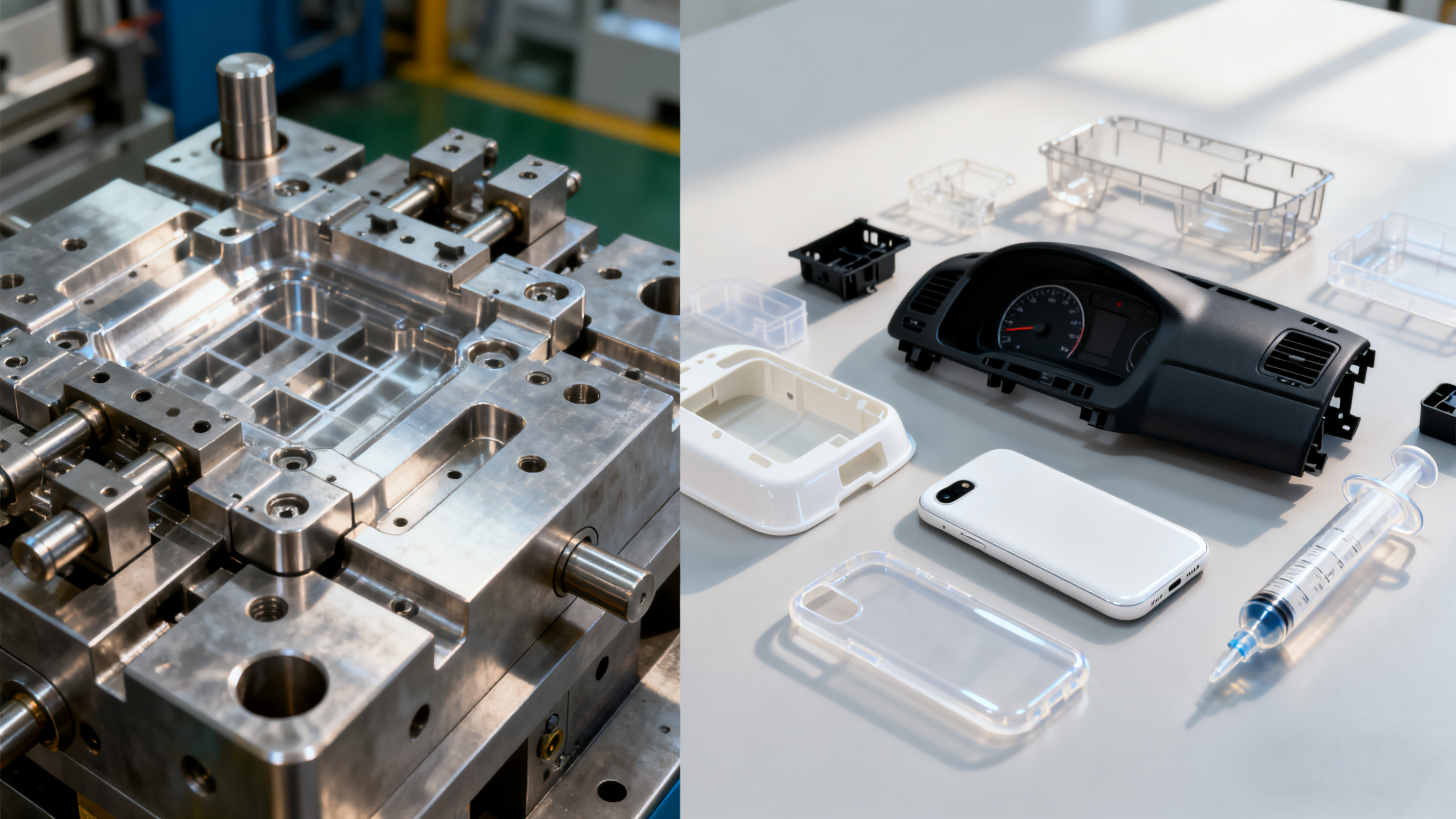

The solution to these challenges lies in partnering with a manufacturer that offers profound expertise and a commitment to quality. When seeking plastic product customization China, it's not enough to find a low-cost producer; you need a team of seasoned professionals. At Guangdong Engineering Plastics Industries, our team is comprised of senior engineers with 15 to 25 years of specialized experience. This depth of knowledge is invaluable. It allows us to provide comprehensive design guidance, recommend the optimal materials for your specific application—whether it's high-performance PEEK, durable PPS, versatile Nylon, or cost-effective ABS—and refine your concept for manufacturability. This collaborative approach eliminates guesswork, reduces the risk of errors, and ensures that the final product is both functional and economically viable.

Seamless Transition from Prototype to Mass Production

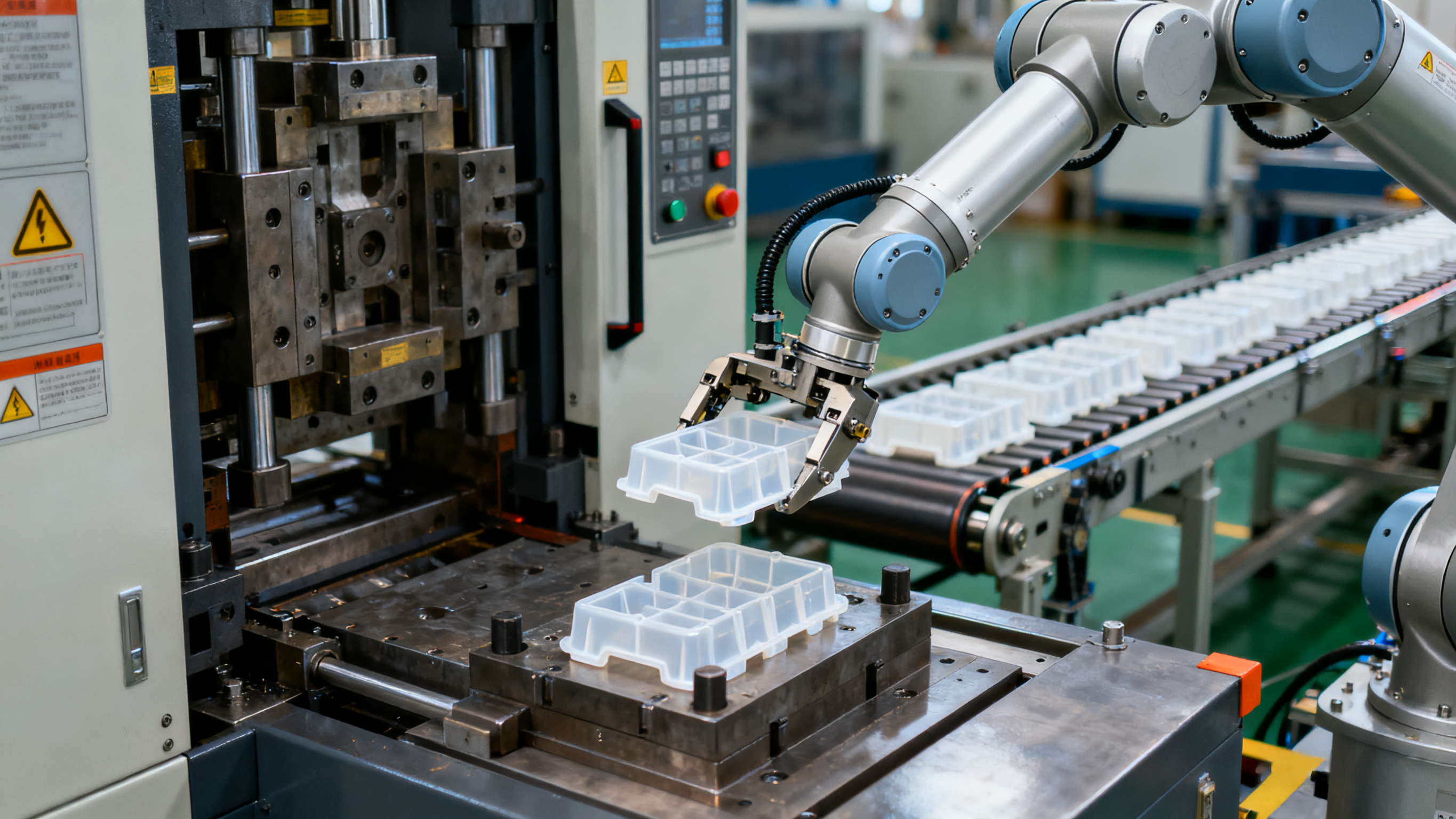

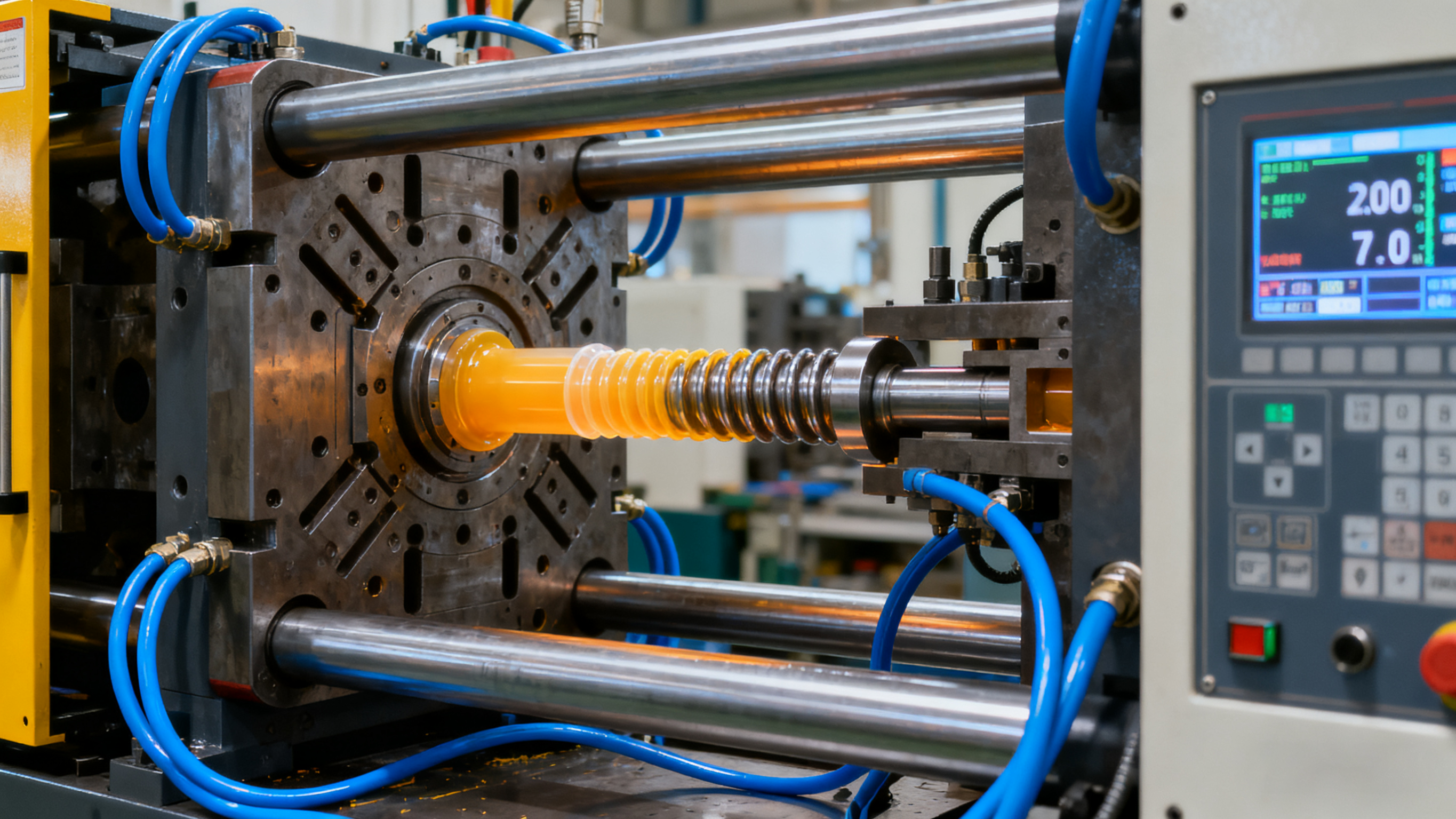

One of the most common pitfalls in product development is the gap between a successful prototype and full-scale production. A prototype that works perfectly in a lab setting may be difficult or expensive to manufacture in large quantities. This is why working with a vertically integrated plastic parts OEM factory is a significant advantage. By managing the entire lifecycle from initial design and prototyping to mass production under one roof, we ensure perfect consistency and quality control. The same engineers who helped perfect your prototype oversee its transition to the production line. This seamless workflow eliminates communication breakdowns between different vendors, streamlines the process, and guarantees that the final components are identical to the approved prototype, meeting your exact specifications every time.

The Advantage of a Full-Service Plastic Parts OEM Factory

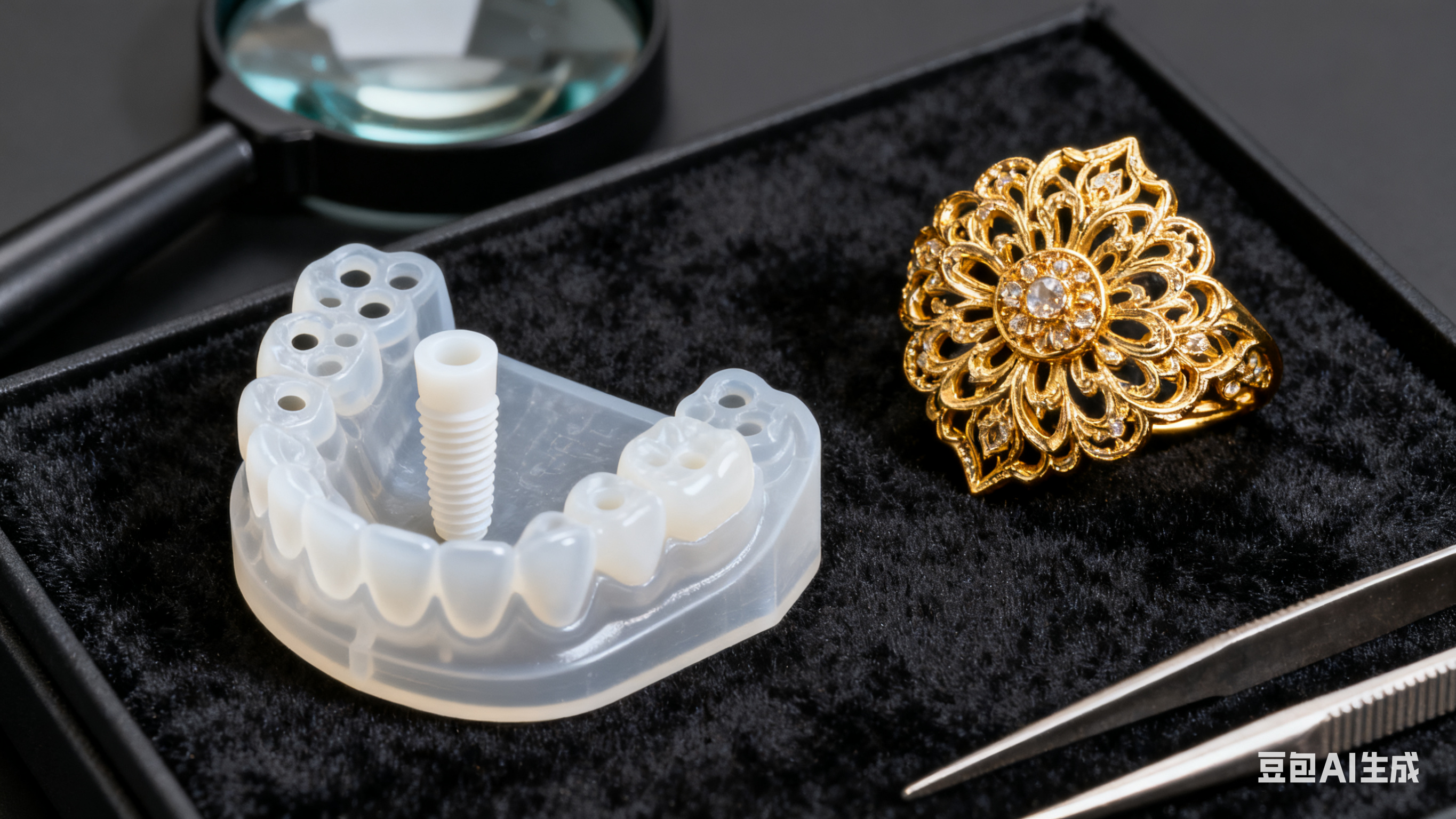

A truly effective manufacturing partner offers more than just production; they provide a full suite of services that add value at every step. As a comprehensive plastic parts OEM factory, we leverage our extensive research and development capabilities to innovate and solve problems. Our expertise isn't limited to a single type of component. We manufacture a wide array of custom engineering plastic products, including intricate gears, high-tolerance pulleys, durable sealing rings, and low-friction bearings. This versatility demonstrates our capacity to handle complex projects and diverse requirements. Choosing a single, capable plastic prototyping manufacturer for all your needs simplifies your supply chain, enhances accountability, and fosters a long-term partnership built on trust and shared success.

Partnering for Global Success in Plastic Manufacturing

Ultimately, overcoming the hurdles of plastic product development requires a partner you can trust to deliver quality, innovation, and reliability on a global scale. The problems of inconsistent quality, design flaws, and production delays are solved by experience, integration, and a customer-centric approach. We are proud to serve a diverse international clientele, with our products being exported to the USA, UK, Canada, Germany, and beyond, earning us a strong reputation for excellence worldwide. By choosing Guangdong Engineering Plastics Industries, you are not just hiring a supplier; you are collaborating with a dedicated team of experts ready to bring your most ambitious projects to life, from initial concept to global distribution.