The Challenges of Machining Components

In the modern manufacturing industry, machining components is a critical operation that demands precision, efficiency, and expertise. Businesses often encounter difficulties in sourcing or producing high-grade components that meet stringent specifications. This can be further complicated by the need for materials that offer durability, resilience, and adaptability to diverse manufacturing conditions. Selecting appropriate materials and processes is crucial to success, and failing to do so can lead to premature wear, breakdowns, and increased costs for companies.

Solutions Through Expert Engineering

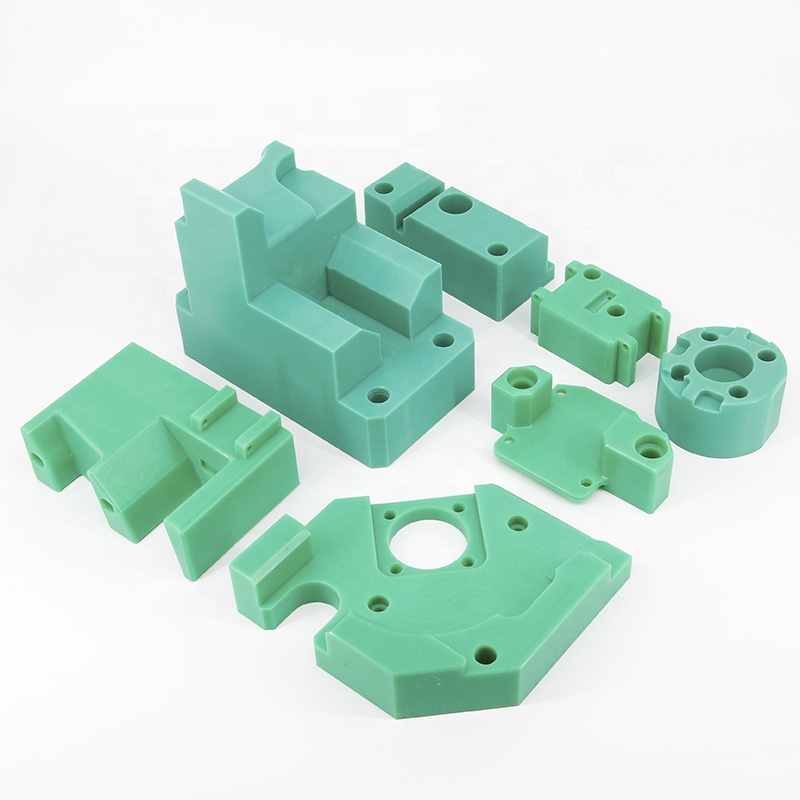

One effective solution to the challenges of machining components lies in leveraging advanced engineering plastics and specialized machining techniques. For instance, utilizing Plastic Turning Machining offers significant advantages. Plastic materials such as Nylon, ABS, and PTFE can be precisely turned into complex shapes, enabling the production of components that are lightweight, corrosion-resistant, and ideal for applications requiring minimal friction. This process is not just about turning a piece of raw plastic but achieving precision that ensures components function seamlessly even under demanding conditions.

The Benefits of Pom Turning Machining

In addition to Plastic Turning Machining, Pom Turning Machining serves as another viable solution for creating reliable components. POM, or polyoxymethylene, is a highly crystalline thermoplastic that provides excellent mechanical properties, making it suited for high-performance machining tasks. By opting for Pom Turning Machining, companies can achieve components that possess high rigidity, low wear, and outstanding dimensional stability. Such characteristics make POM a preferred choice for manufacturing gears, bearings, and other intricate parts.

Guangdong Engineering Plastics Industries Group Co., Ltd.: Your Trusted Partner

When it comes to machining components with precision and reliability, Guangdong Engineering Plastics Industries Group Co., Ltd. stands out as an industry leader. Our team of senior engineers brings 15-25 years of seasoned expertise to every project, enabling us to provide tailored customization and holistic design, research, and development capabilities. Our manufacturing portfolio is extensive, covering a variety of engineering plastic products made from PEEK, PPS, Nylon, ABS, and PTFE, among others.

Serving a global clientele, including renowned markets in the USA, UK, Canada, and Germany, we've built a strong international reputation for delivering high-quality engineering plastic components. Whether you require gears, pulleys, or complex sealing solutions, our company is committed to providing innovative and effective solutions. With our advanced machining techniques and comprehensive industry knowledge, we can help you overcome the challenges of machining components, ensuring efficiency and excellence in your production processes.