Custom Online

3D Printing Services

On-demand 3D printing for rapid prototyping and production in as fast as 3 days. Get an instant quote today.

- ISO 9001: 2015 Certified Quality

- Tolerances as fine as ±0.2 mm.

- Global Delivery in as Fast as 3 Days

Start A New Injection Molding Quote

Our 3D Printing Services

EnQi offers a comprehensive suite of high-quality additive manufacturing solutions, encompassing technologies like FDM, SLA, SLS, and SLM. This enables the production of both plastic and metal parts, supporting applications from functional prototyping to end-use part production.

3D printing is ideal for creating one-off parts, small batches, and complex geometries that are difficult or impossible to achieve with traditional manufacturing methods.

Why Choose EnQi?

At EnQi,We provide high-quality, dependable 3D printing solutions that accelerate your rapid prototyping and production.

Comprehensive 3D Printing Technologies

We provide a full range of industrial 3D printing processes—including FDM, SLA, SLS, and DMLS—enabling you to select the optimal technology based on material needs, surface quality, mechanical properties, and application requirements.

Rapid Parts Delivery

Leveraging our streamlined workflow and in-house production capabilities, we deliver custom 3D-printed parts in as little as 72 hours, helping you speed up product development and shorten lead times.

From Prototyping to Low-Volume Production

Whether you're validating a design concept or scaling to low-volume manufacturing, we efficiently convert your 3D models into high-quality plastic, metal, and elastomeric parts.

Dedicated Engineering Support

Our experienced engineering team supports you through every phase—from 3D model optimization and DFAM to material recommendation and tolerance analysis—collaborating closely to ensure your parts meet performance and budget goals.

Start Your Custom 3D Printing Project Today.

All information and uploads are secure and confidential.

3D Printing Technologies

EnQi offers high-quality additive manufacturing services, including FDM, SLA, SLS, and SLM, enabling fast, precise 3D printing in plastics and metals. Ideal for rapid prototyping, functional parts, and low-volume production, our solutions handle complex geometries that traditional methods can’t achieve

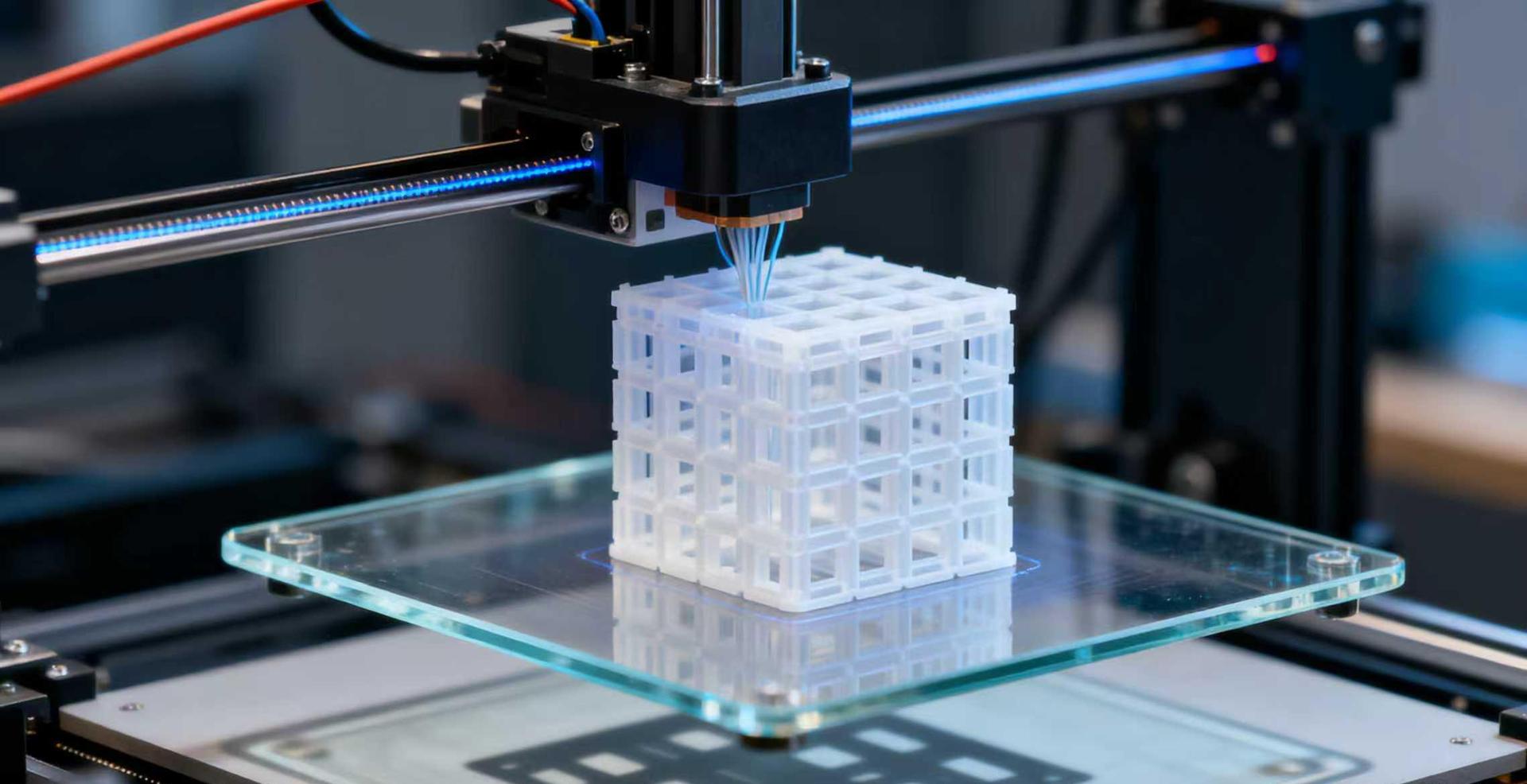

1. FUSED DEPOSITION MODELING (FDM)

Affordable for basic prototypes

Fused Deposition Modeling (FDM), also called Fused Filament Fabrication (FFF), is a leading additive manufacturing technique known for its accessibility and versatility. It constructs parts by selectively depositing layers of molten thermoplastic, guided by a computer-controlled nozzle.

The process begins with a solid filament spool. The filament is fed to an extruder, where it is melted and laid down with precision along a pre-programmed path. Each deposited layer fuses to the one below upon cooling, allowing for the creation of complex geometries with minimal waste.

This makes FDM ideal for prototyping, custom parts, and educational applications.

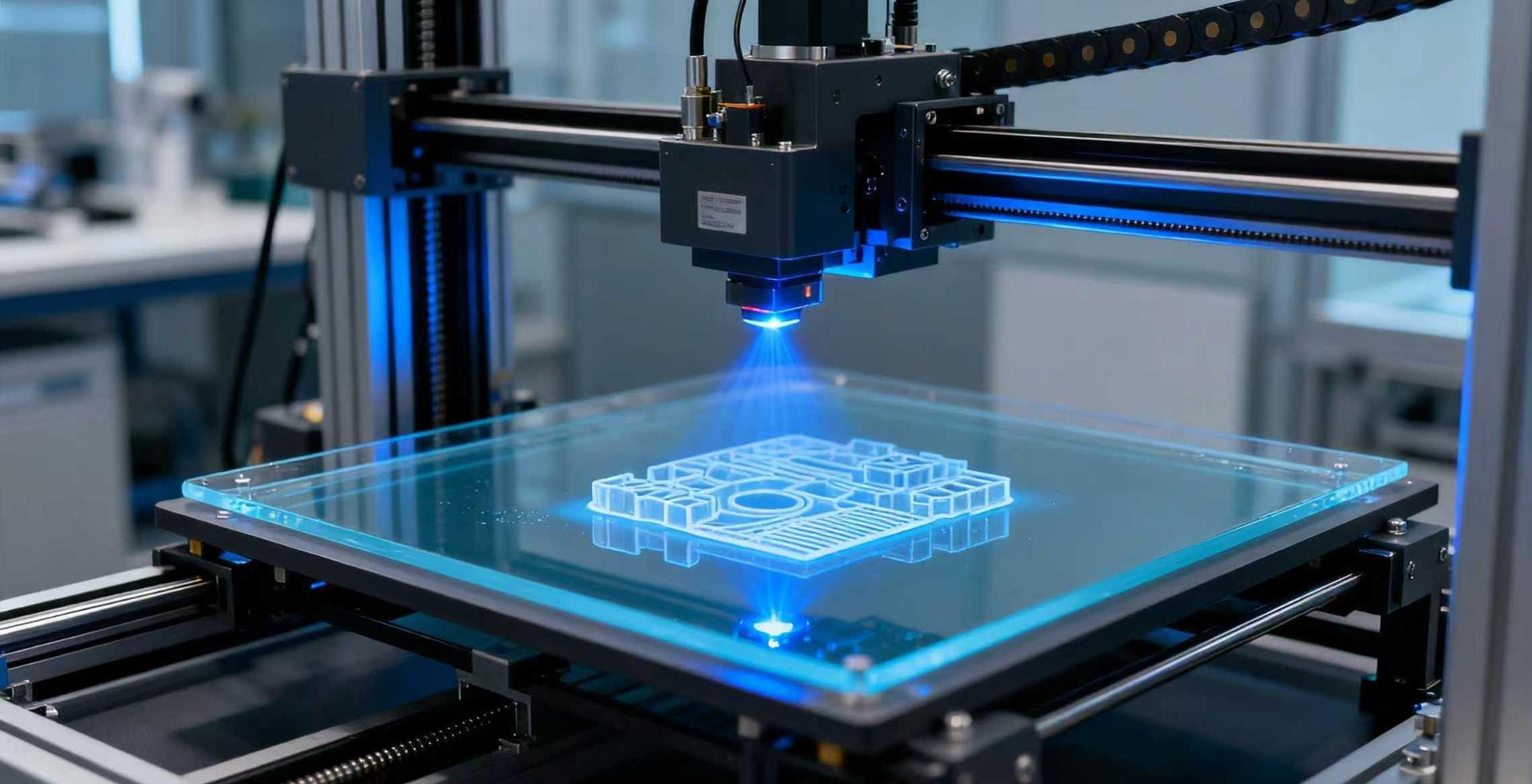

2. STEREOLITHOGRAPHY (SLA)

Visual prototype

Stereolithography (SLA) is a pioneering additive manufacturing technology that uses a laser to cure liquid resin into solid parts, differing significantly from filament-based FDM. It is renowned for producing parts with the highest resolution and smoothest surface finish among common 3D printing processes.

During printing, a laser beam is guided across a vat of liquid photopolymer resin by a dynamic mirror system, curing precise cross-sections layer by layer. The build platform adjusts its height after each layer is completed.

While its material selection is confined to photopolymers, SLA is unparalleled for applications demanding extreme detail and smoothness, such as prototypes, jewelry, and dental models. As one of the first 3D printing methods developed, it remains a cornerstone of professional additive manufacturing.

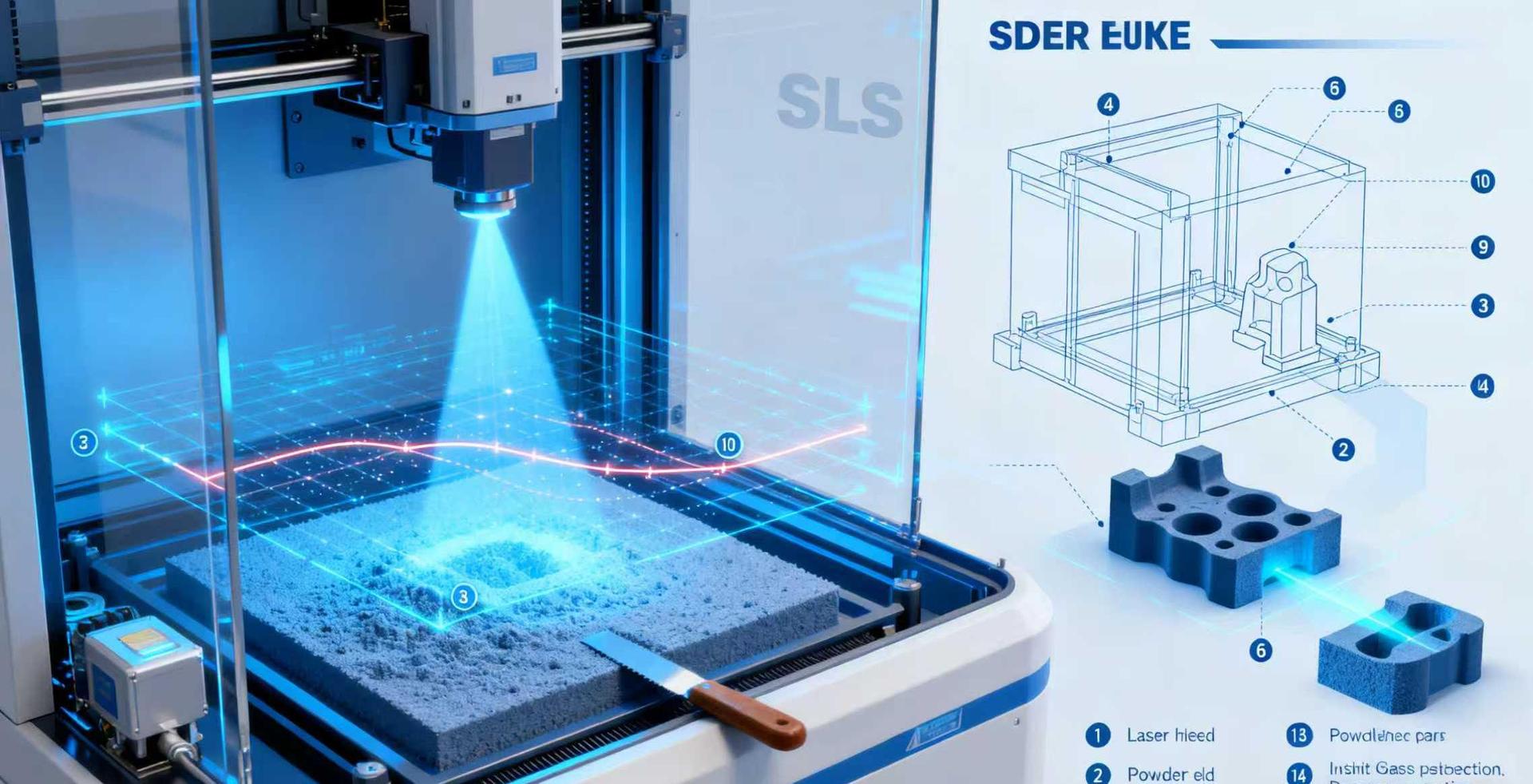

3. SELECTIVE LASER SINTERING (SLS)

Functional prototyping and low-volume parts

Selective Laser Sintering (SLS) is a powder bed additive manufacturing process used to make parts from thermoplastic polymer powders. It is commonly used for functional parts, since SLS printed components have good mechanical properties.

An SLS 3D printer works by sintering areas of plastic powder with a laser. During the process, a thin layer of powder is distributed evenly across the build platform, after which the laser sinters selected areas of the 2D layer. When the layer is complete, the platform is lowered, more powder is added, and the laser sinters the next layer.

When all layers are complete, the part is left to cool. Unused powder is kept to be used again, and the part is cleaned to remove excess material.

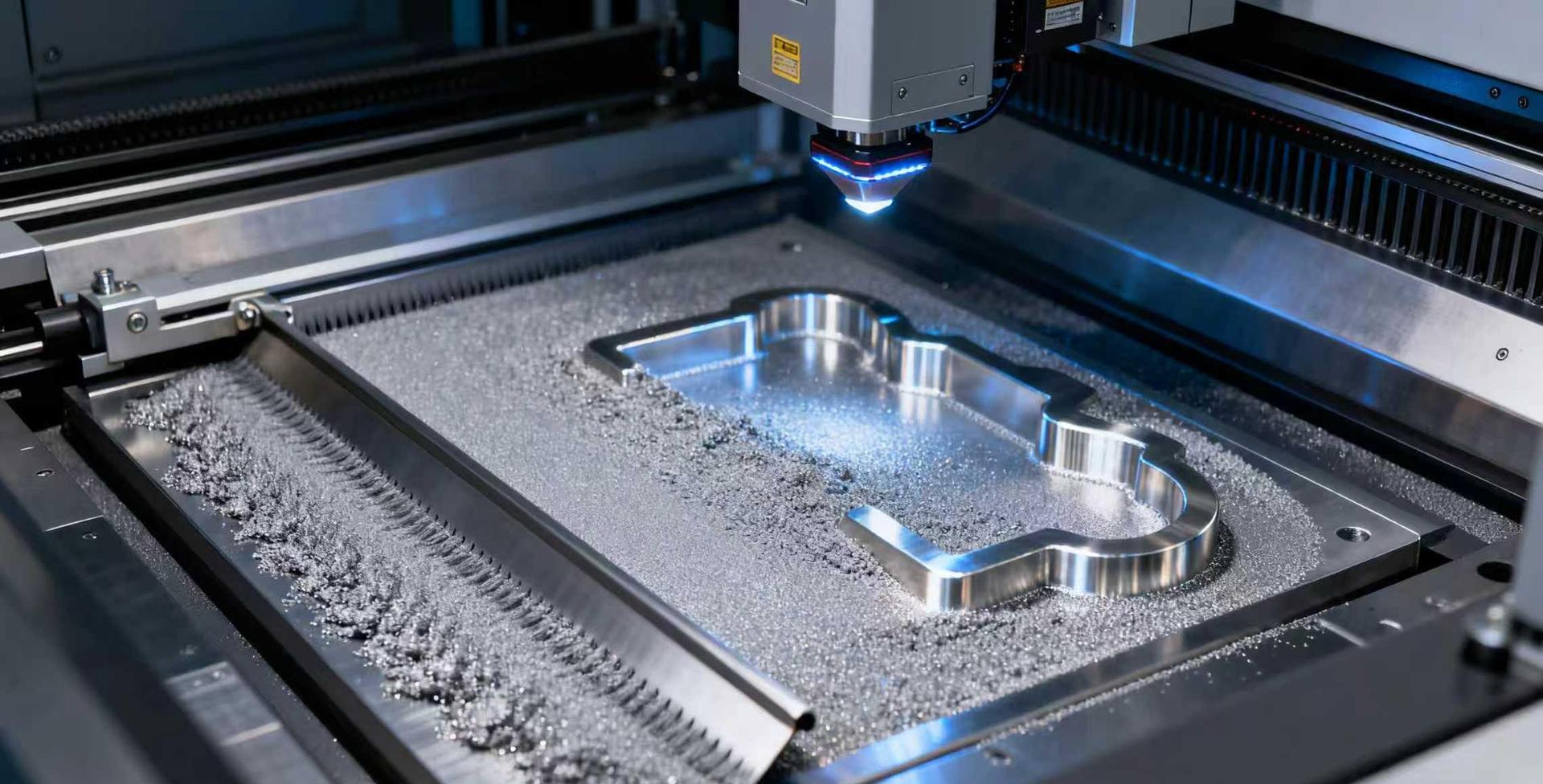

4. SELECTIVE LASER MELTING (SLM)

Parts for functional end use

Selective Laser Melting (SLM) is a metal 3D printing process that builds high-strength parts layer by layer from fine metal powder. Inside a sealed, inert gas-filled chamber, a powerful laser selectively melts the powder based on the cross-sections of a CAD model.

Once a layer is completed, the build platform lowers slightly, and a fresh layer of powder is spread across the surface to continue the build. Unlike sintering processes, SLM fully melts the metal powder, resulting in parts with excellent mechanical properties and near-wrought strength.

This makes it suitable for highly demanding applications in aerospace, automotive, medical, and more. The technology also allows for the production of complex geometries, internal channels, and lightweight structures that are difficult or impossible to achieve with traditional manufacturing.

Looking for more additive manufacturing solutions?

Contact Us3D Printing Technologies Compared: Which One is Right for You?

When selecting a 3D printing technology, begin by defining your key design requirements and the intended end use of the part. This will help determine the most suitable printing method for your application. Refer to the table below for a comparison of available technologies.

| Technologies | FDM | SLA | SLS | SLM |

|---|---|---|---|---|

✓Advantages |

|

|

|

|

✓Disadvantages |

|

|

|

|

✓Typical layer height | 50-400 microns | 25-100 microns | 100-120 microns | 20-50 microns |

FDM

Advantages

- •Most affordable 3D printing process for plastic parts

Disadvantages

- •Relatively Low Surface Quality.

- •Visible layer lines, weaker layer bonding.

- •Not cost-effective for high volumes

Typical layer height

50-400 microns

SLA

Advantages

- •High resolution

- •No visible layer lines, smooth finish

- •Ideal for transparent parts

Disadvantages

- •Printers more expensive than FDM

- •Weak parts will degrade with sunlight

- •Extensive post-processing required

Typical layer height

25-100 microns

SLS

Advantages

- •Consistent strength

- •No support structures needed

Disadvantages

- •Porosity

- •Rough surface finish

- •High cost

Typical layer height

100-120 microns

SLM

Advantages

- •Strong and hard parts

- •Ideal for complex shapes

Disadvantages

- •Limited build size

- •Thermal stress and warping

- •High cost

Typical layer height

20-50 microns

precision.materials.title

PEEK

precision.materials.items.PEEK.desc

품질 관리

EnQi Manufacturing은 품질을 최우선으로 생각합니다. 모든 부품이 최고 수준의 정밀성과 신뢰성을 충족하도록 제조 공정 전반에 걸쳐 엄격한 품질 관리 조치를 시행합니다. 당사의 포괄적인 품질 보증 시스템에는 제품의 일관성과 우수성을 유지하기 위한 첨단 검사 도구와 기술이 포함되어 있습니다.

진행 중 검사

당사의 품질 관리는 공정 중 검사에서 시작됩니다. 각 부품은 생산의 여러 단계에서 설계 사양 준수 여부를 확인하기 위해 검사됩니다. 이러한 선제적인 접근 방식은 제조 공정 초기에 문제를 파악하고 해결하는 데 도움이 됩니다.

최종 검사

모든 부품은 출고 전 철저한 최종 검사를 통해 품질과 정밀도를 검증합니다. 첨단 측정 도구와 기술을 사용하여 각 부품이 필요한 사양과 표준을 충족하는지 확인합니다.

정밀 측정 도구

저희는 좌표측정기(CMM), 광학 비교기, 레이저 스캐너 등 다양한 정밀 측정 도구를 활용하여 CNC 가공 부품의 치수와 공차를 정확하게 측정합니다. 이러한 도구를 통해 모든 부품의 정밀한 공차와 높은 정밀도를 유지할 수 있습니다.

ISO 9001, ISO 14001, IATF 16949 및 AS9100D 인증

품질에 대한 저희의 헌신은 ISO 9001, ISO 14001, IATF 16949 및 AS9100D 인증을 통해 입증되었습니다. 이 국제 표준은 저희의 품질 관리 시스템이 효과적이고 지속적으로 개선되어 고객에게 일관되고 고품질의 제품을 제공할 수 있도록 보장합니다.

지속적인 개선

저희는 지속적인 개선을 중요하게 생각하며, 개선이 필요한 부분을 파악하기 위해 프로세스와 관행을 정기적으로 검토합니다. 최신 기술에 투자하고 직원 교육을 통해 품질과 혁신에 대한 명성을 유지하기 위해 최선을 다합니다.

고객 리뷰

혁신적인 기업의 신뢰를 받다

산업 응용 분야

도움이 필요하신가요? 저희가 도와드리겠습니다.

궁금한 점이 있거나 도움이 필요하시면 저희 팀이 연중무휴 24시간 지원을 제공합니다. 아래 방법을 통해 문의해 주세요.