We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

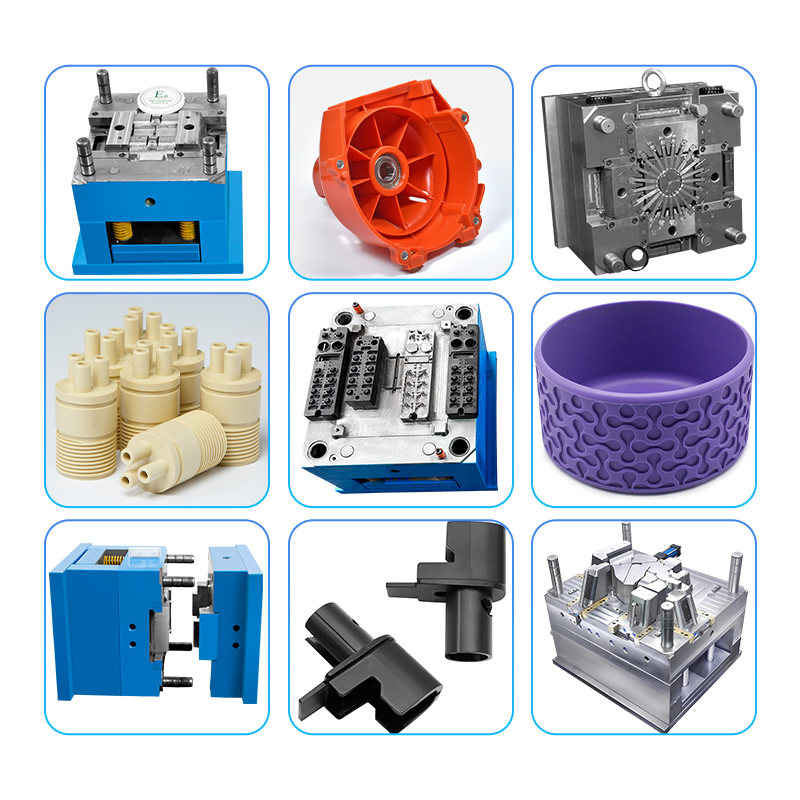

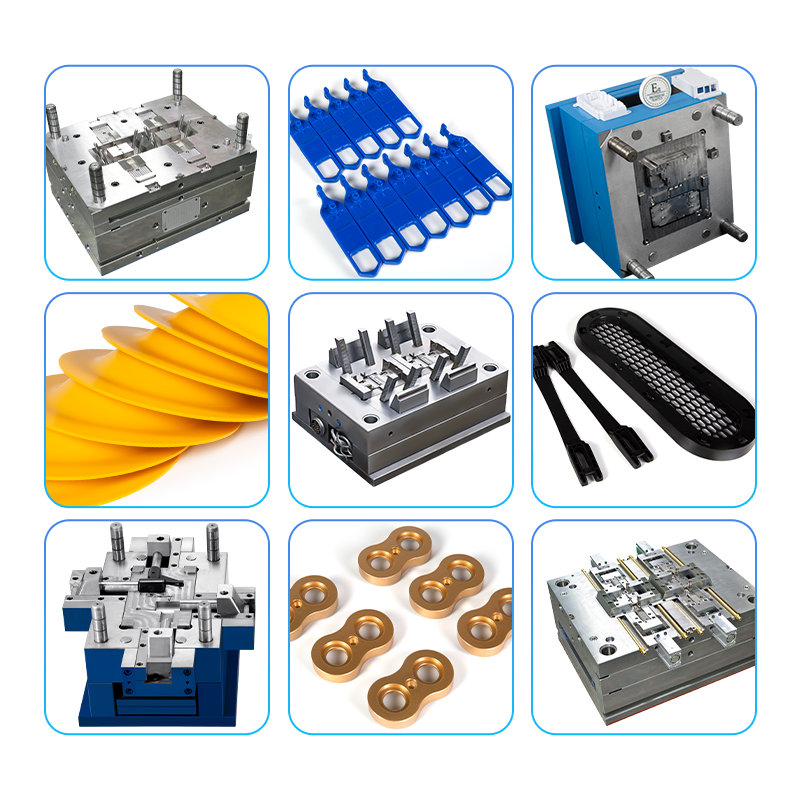

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

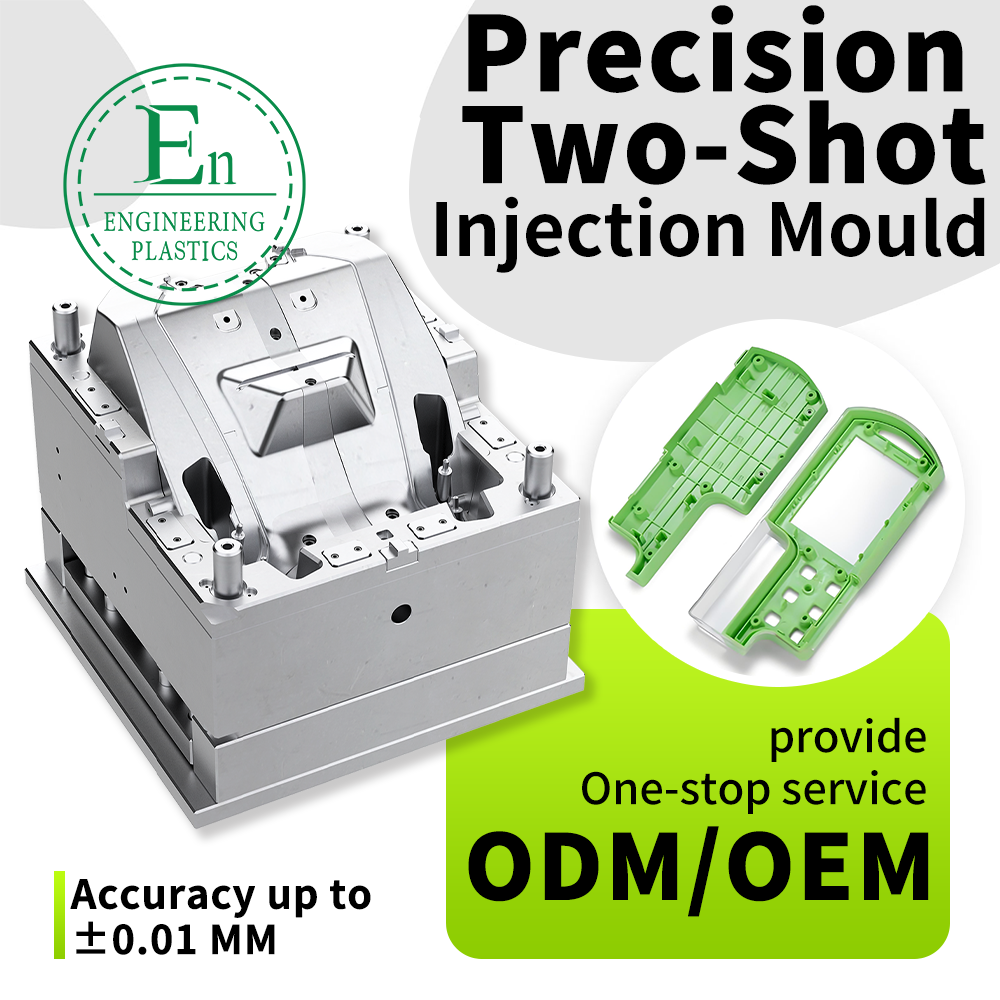

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

The modern manufacturing landscape owes much of its efficiency and versatility to the precision of plastic production. At the core of this industry is the injection mold machine, a powerful piece of equipment responsible for creating a vast array of plastic components we use every day, from complex automotive parts to simple household items. Understanding how this technology works is the first step in appreciating the intricate process of bringing a plastic product from a concept to a tangible reality.

The Mechanics of the Injection Moulding Machine

A state-of-the-art injection moulding machine operates on a cyclical process that is both precise and rapid. It begins by melting granular plastic pellets into a molten liquid state. This molten plastic is then injected under high pressure into a custom-designed mold cavity. Once the mold is filled, the material is cooled to solidify it into the desired shape. Finally, the mold opens, and the finished part is ejected, ready for the cycle to begin again. This highly repeatable process allows for the mass production of identical parts with incredible accuracy, making the injection moulding machine an indispensable tool for industries requiring high volume and consistent quality.

The Critical Role of Injection Mould Plastic

While the machine provides the process, the quality and performance of the final product are determined by the material used—the injection mould plastic. The selection of the right polymer is a science in itself. Materials range from common plastics like ABS to high-performance engineering plastics such as PEEK, PPS, Nylon, and PTFE. Each material offers a unique set of properties, including mechanical strength, temperature resistance, chemical inertness, and flexibility. Choosing the correct injection mould plastic is crucial for ensuring the final component can withstand its intended operational environment, whether it's a high-friction gear or a durable sealing ring.

Partnering with Experts for Superior Results

Successfully navigating the complexities of plastic manufacturing requires more than just access to an advanced injection mold machine; it demands deep expertise. At Guangdong Engineering Plastics Industries Group Co., Ltd., our team of senior engineers brings decades of experience to every project. We understand that creating a superior product involves a holistic approach, from initial design and material selection to the final production run. Our comprehensive R&D capabilities allow us to provide personalized customization, ensuring that the chosen plastic and mold design are perfectly optimized for your specific application. This commitment to excellence has allowed us to serve a global clientele, building a reputation for delivering high-quality, reliable engineering plastic products.