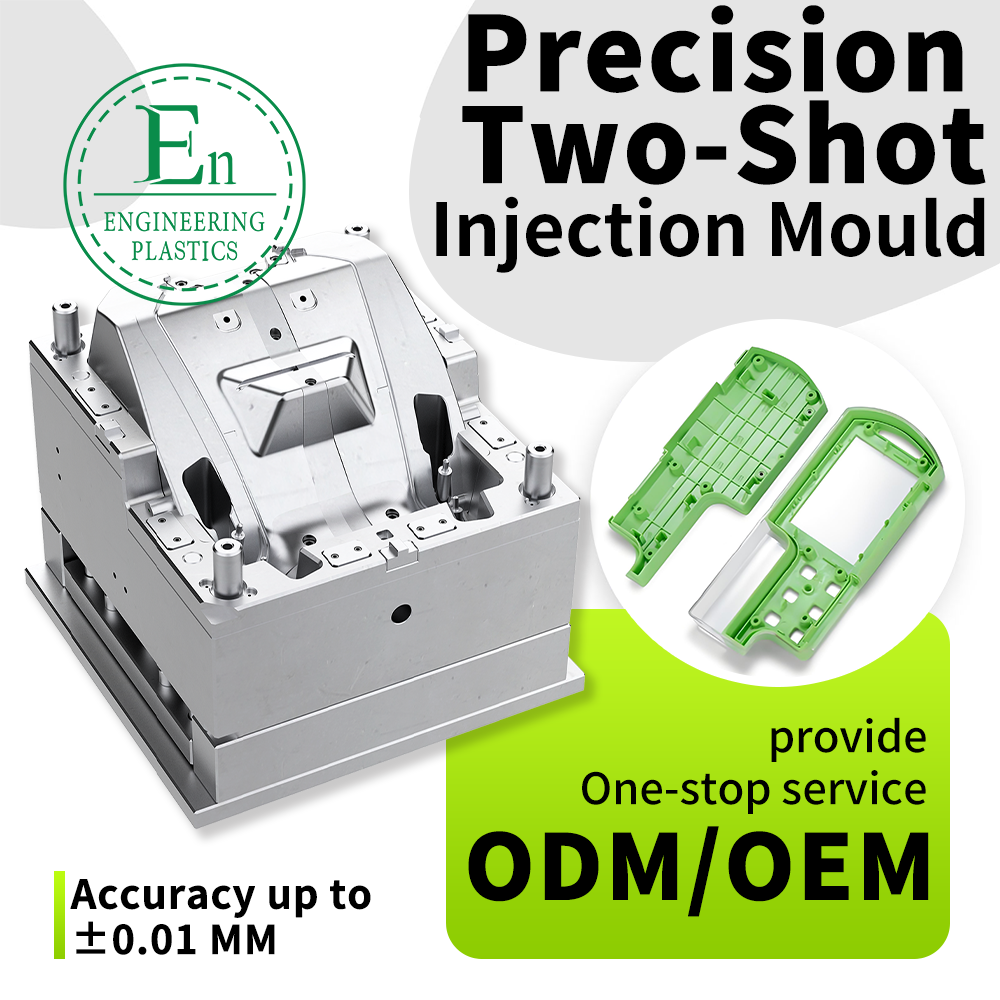

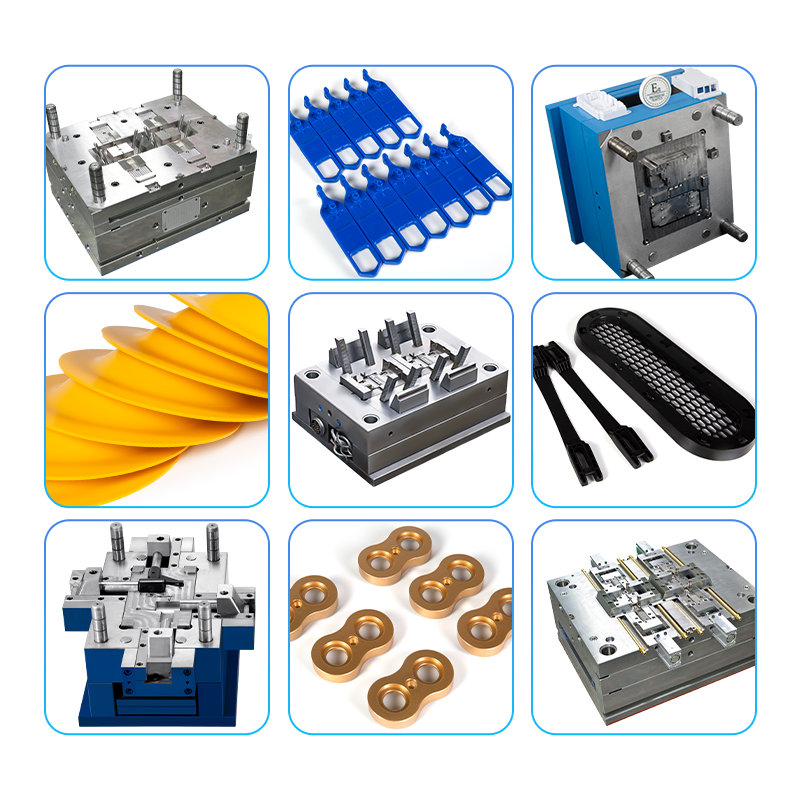

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In today's competitive market, product designers face a constant challenge: creating products that are not only durable and functional but also comfortable and aesthetically pleasing. A single rigid plastic part often falls short, feeling cheap, offering a poor grip, or failing to protect sensitive internal components from shock and vibration. This gap in performance can significantly impact user experience and brand perception. Fortunately, an innovative manufacturing process known as Overmolding provides a sophisticated solution, allowing for the creation of multi-material components that offer the best of both worlds.

What is Overmolding?

Overmolding is a multi-step injection molding process that creates a single, seamless part from two or more different materials. The process typically begins by molding a rigid plastic substrate—often made from robust materials like Nylon or ABS. This first piece is then placed into a second mold, where a different material, usually a softer, more flexible polymer, is injected over or around the original substrate. The result is a chemically or mechanically bonded composite part that combines the distinct properties of each material. This technique is the key to achieving complex designs that are impossible with traditional single-shot molding.

The Advantages of a Superior Grip and Feel

One of the most popular applications of this technology is soft touch overmolding. Think about the handle of a high-quality power tool or the casing of a modern electronic device. The comfortable, non-slip grip that enhances usability and provides a premium feel is often achieved through this method. The problem with hard, slick plastic surfaces is that they can be difficult to hold, especially in wet conditions, and they do little to dampen vibrations. By adding a layer of a softer material, soft touch overmolding directly solves this issue. It improves ergonomics, adds shock absorption, creates water-resistant seals, and enhances the overall visual appeal of a product with contrasting colors and textures.

Navigating the Complexities of TPE Overmolding

While the benefits are clear, the process itself requires deep technical expertise. Successful TPE overmolding—using Thermoplastic Elastomers as the soft material—depends critically on the chemical compatibility between the substrate and the overmold material. If the materials are not correctly matched, the bond between them will be weak, leading to delamination, peeling, and ultimate product failure. Factors like mold design, processing temperatures, and injection pressure must be precisely controlled to ensure a permanent, seamless bond. This complexity is why partnering with a seasoned manufacturing expert is not just beneficial, but essential for achieving a high-quality and reliable final product.

Partnering with Experts for Flawless Results

At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in turning complex design challenges into reality. Our team of senior engineers, with 15-25 years of hands-on expertise, understands the intricate science behind the Overmolding process. We work closely with our clients, from design and research to final production, ensuring the perfect material selection and process parameters for every unique application. Whether you require a durable Nylon substrate for strength or a specific TPE overmolding solution for ergonomic feel, our comprehensive capabilities allow us to deliver customized, high-performance components. Our commitment to quality has earned us a strong global reputation, serving clients across the USA, UK, Canada, and Germany. Don't let material limitations compromise your product's potential. Contact us today to learn how our advanced manufacturing solutions can bring your vision to life.