We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

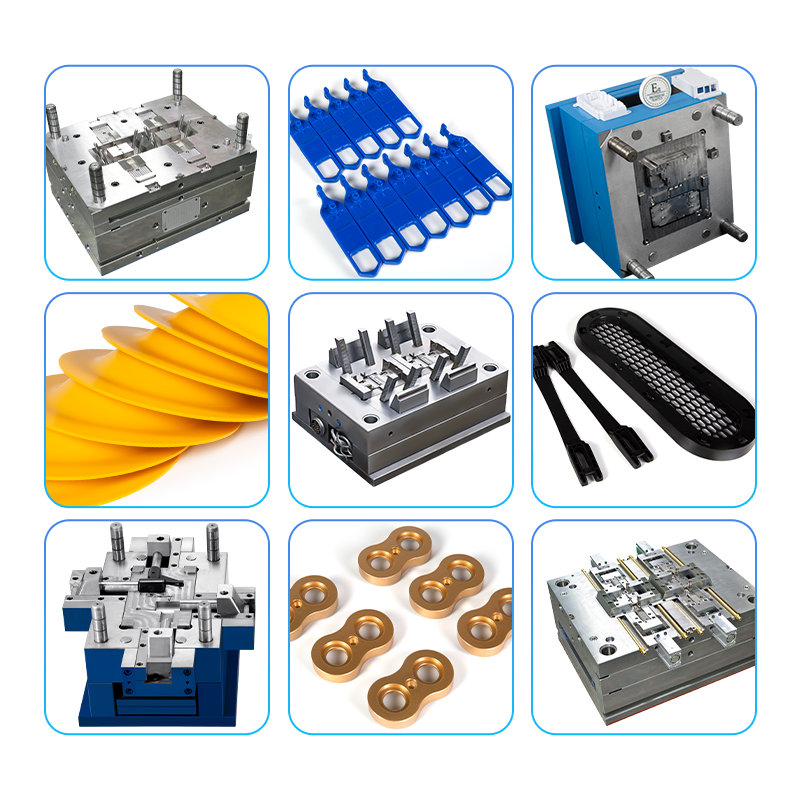

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

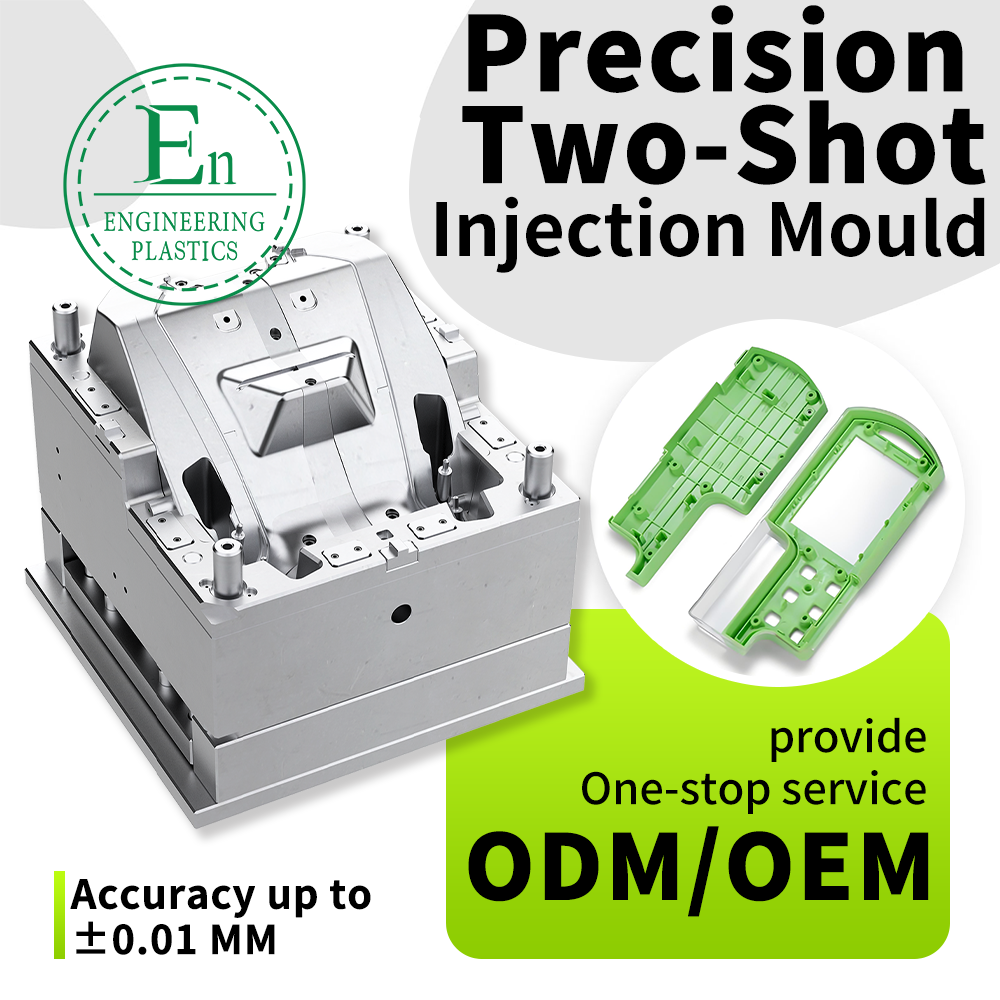

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In today's advanced manufacturing landscape, the precision and durability of components are paramount. High-quality injection mould products form the backbone of countless industries, from automotive and electronics to medical devices and consumer goods. The process of creating these essential parts requires a blend of advanced technology, deep material science knowledge, and engineering expertise. At Guangdong Engineering Plastics Industries Group Co., Ltd., we have cultivated these capabilities to become a trusted global partner, delivering custom solutions that meet the most demanding specifications for clients worldwide.

The Foundation of Quality: Comprehensive Injection Moulding Services

Achieving superior end-products begins with exceptional injection moulding services. This is more than just a manufacturing process; it's a comprehensive service that encompasses design consultation, material selection, mold creation, and precision production. Our team's strength lies in our senior engineers, who bring 15 to 25 years of dedicated expertise to every project. This depth of experience allows us to offer personalized customization and robust research and development capabilities. We collaborate closely with our clients to understand their unique challenges, ensuring the final component is optimized for performance, longevity, and cost-effectiveness. Our commitment to excellence in our services is the reason we can consistently produce complex and reliable engineering plastic parts.

Diverse Materials for Demanding Applications

The versatility of injection moulding is fully realized through the strategic use of advanced materials. Different applications require unique properties, whether it's high-temperature resistance, chemical inertness, or exceptional mechanical strength. We specialize in working with a wide array of high-performance engineering plastics, including PEEK, PPS, Nylon, ABS, and PTFE. This allows us to manufacture a diverse range of injection mould products, such as precision gears, durable pulleys, high-pressure sealing rings, and low-friction bearings. By matching the right material to the right application, we ensure our products deliver unparalleled performance and reliability, helping our clients innovate and succeed in their respective markets.

Sourcing a Partnership, Not Just an Injection Mold for Sale

For businesses looking to scale their production, finding an injection mold for sale is a critical step. However, this investment goes beyond the physical tool itself. It is about establishing a relationship with a provider who guarantees quality, precision, and long-term value. A high-quality mold is the key to consistent and efficient production runs, minimizing defects and maximizing output. At Guangdong Engineering Plastics Industries Group Co., Ltd., we offer more than just a product; we offer a partnership built on trust and proven results. Our strong global reputation, with exports to the USA, UK, Canada, Germany, and other leading markets, stands as a testament to the quality and reliability that we deliver with every project and every mold we create.

Your Global Partner for Engineering Plastic Solutions

Ultimately, success in modern manufacturing hinges on the quality of your components and the expertise of your partners. From initial design to the final production of intricate injection mould products, our team provides an end-to-end solution designed for excellence. Whether you require comprehensive injection moulding services or are seeking a dependable injection mold for sale, Guangdong Engineering Plastics Industries Group Co., Ltd. has the experience, technology, and commitment to help you achieve your goals. We pride ourselves on building lasting relationships with our domestic and international clients, driving innovation one precision part at a time.