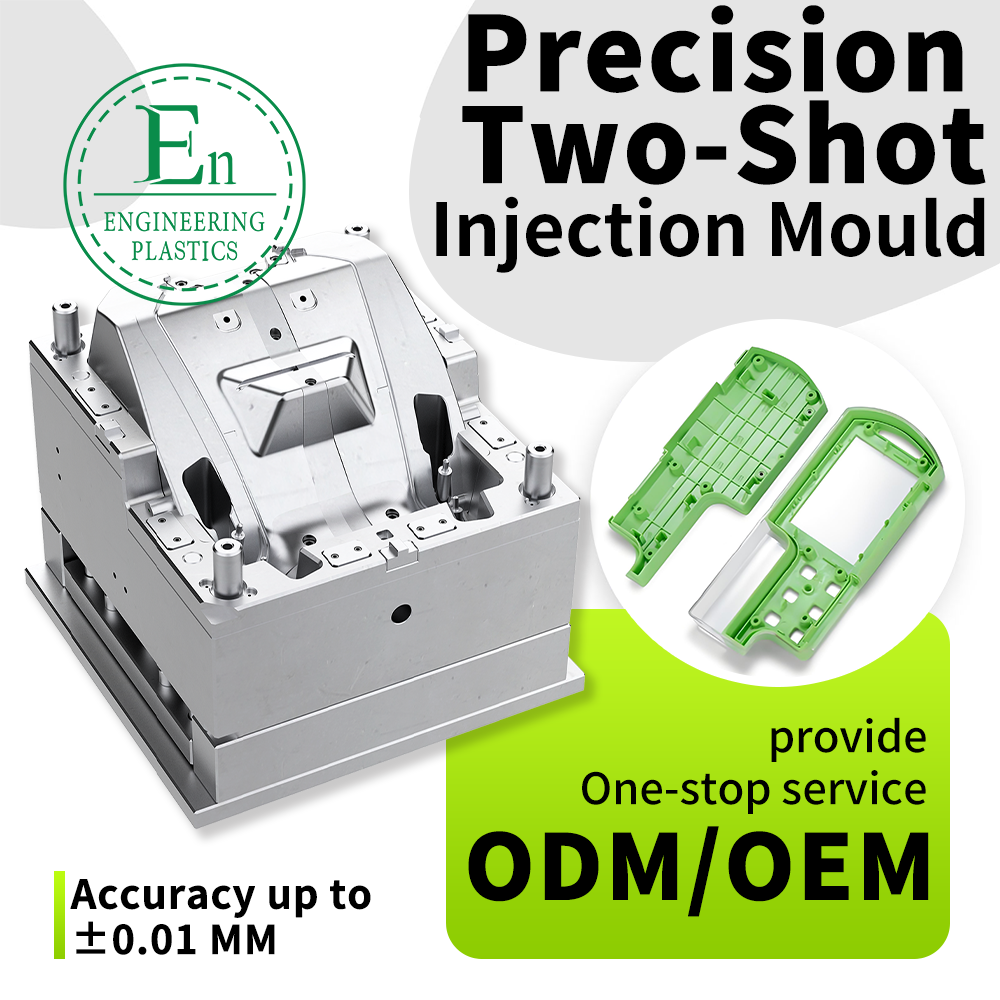

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

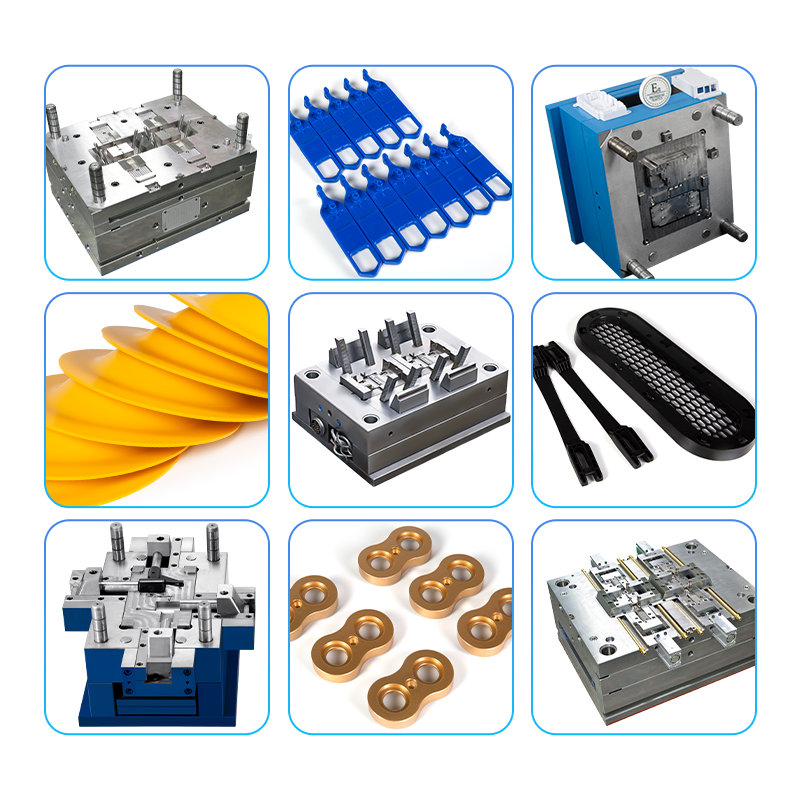

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Finding the right injection moulding factory is a pivotal decision for any business that relies on high-quality, precision-engineered plastic components. This choice directly impacts product quality, production timelines, and overall project costs. In a global marketplace, partnering with a manufacturer that combines technical expertise with reliable service is essential for success. Whether you are developing a new product or seeking to optimize an existing supply chain, understanding the capabilities of your manufacturing partner is the first step towards achieving your goals.

What to Look for in a Top-Tier Injection Molding Factory

When evaluating a potential injection molding factory, several key attributes separate the best from the rest. Foremost among these is deep engineering expertise. A premier factory is not just a production line; it is a hub of innovation and problem-solving. Look for a team with demonstrable experience, such as senior engineers with 15 to 25 years of dedicated expertise in the field. This level of experience, like that found at Guangdong Engineering Plastics Industries Group Co., Ltd., ensures that complex challenges can be met with comprehensive design, research, and development capabilities. A partner with this depth can offer personalized customization, ensuring your components are perfectly suited for their application.

The Strategic Advantage of Choosing an Injection Mould China Partner

For many companies worldwide, sourcing from an injection mould china partner offers significant strategic advantages. The region's advanced manufacturing infrastructure and experienced workforce provide a powerful combination of cost-effectiveness and large-scale production capability. However, the true benefit lies in partnering with a company that has a proven track record of international excellence. A reliable Chinese manufacturer will have a strong global reputation, exporting to demanding markets such as the USA, UK, Canada, and Germany. This demonstrates a commitment to meeting stringent international quality standards and providing exceptional customer service, making them a trustworthy extension of your own team.

Beyond Standard Parts: The Power of Customization and Material Science

A truly capable injection moulding factory offers more than just mass production; it provides tailored solutions built on a foundation of material science. The ability to work with a wide range of advanced engineering plastics is crucial for modern applications. Materials like PEEK, PPS, Nylon, ABS, and PTFE each have unique properties, and choosing the right one is critical for performance and longevity. Companies with in-house R&D can manufacture a diverse portfolio of products, including high-performance gears, pulleys, sealing rings, and bearings. This versatility signifies a deep understanding of how material choice and design work together to create a superior final product, moving beyond a simple supplier relationship to one of true engineering partnership.