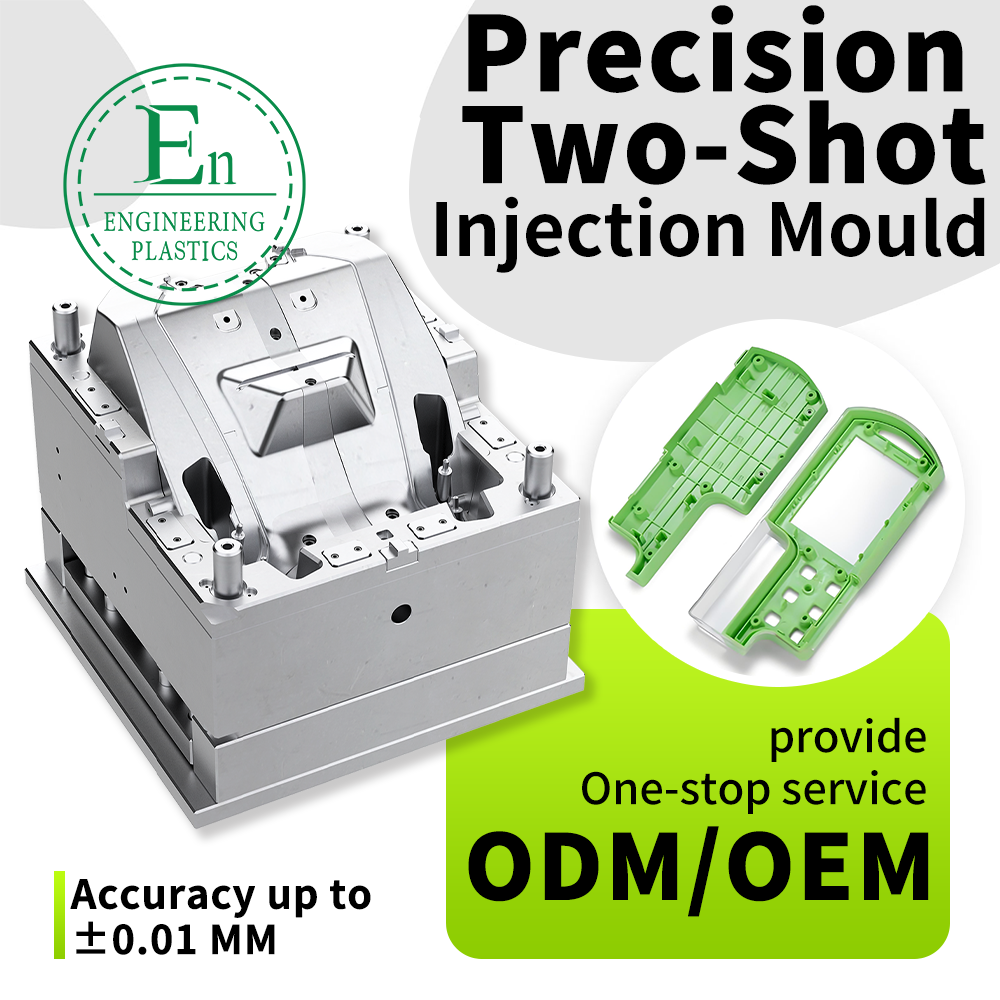

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

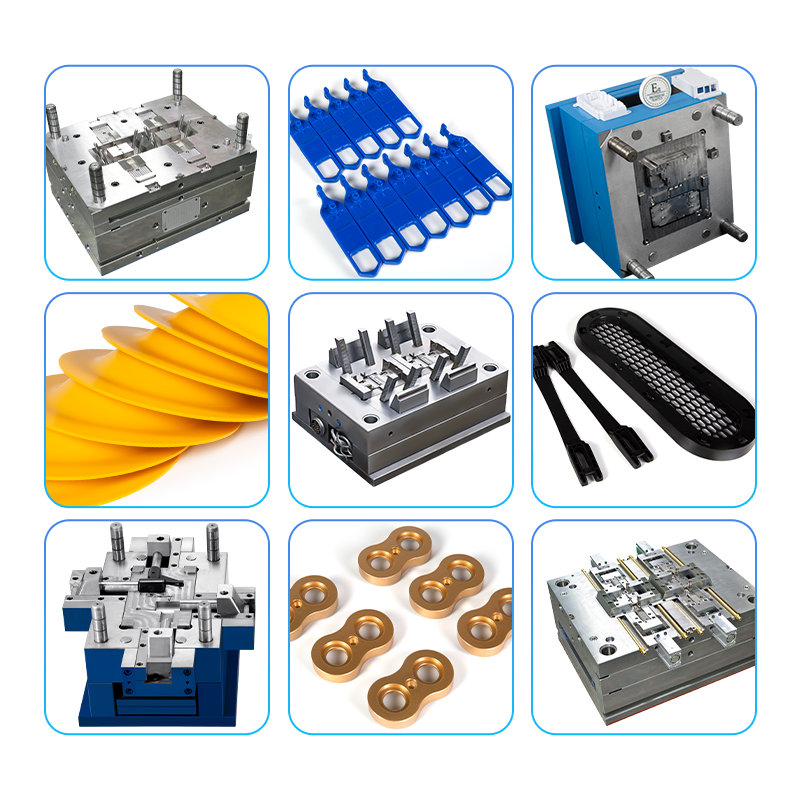

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of modern manufacturing and rapid prototyping, precision and versatility are paramount. A key technology that embodies these qualities is the SILICON MOLD, a tool that has revolutionized how products are developed and produced across countless industries. Creating a high-quality mold requires a deep understanding of material science, intricate design principles, and expert engineering. This is where the extensive experience of a dedicated team, like the seasoned professionals at Guangdong Engineering Plastics Industries Group Co., Ltd., becomes invaluable, transforming complex concepts into tangible, high-fidelity parts.

The Unmatched Versatility of Silicone Moulds

One of the greatest advantages of using silicone moulds is their incredible adaptability. Their applications span from producing intricate food-grade items and medical-grade device components to crafting detailed prototypes for consumer electronics and automotive parts. This versatility stems from the inherent properties of silicone itself. It is highly flexible, allowing for the easy removal of complex parts without damage, a process known as demolding. Furthermore, silicone offers excellent heat resistance and chemical stability, ensuring the mold maintains its integrity and longevity even after repeated use. This ability to capture fine details with exceptional accuracy makes silicone moulds an ideal choice for projects where precision is non-negotiable.

The Art and Science Behind a Silicon Rubber Mold

Creating a perfect silicon rubber mold is a meticulous process that blends artistry with precise science. It begins with a flawless master pattern, which serves as the template for the mold. From there, a high-quality, two-part silicone compound is carefully measured, mixed, and often vacuum degassed to eliminate air bubbles that could compromise the final surface finish. The liquid silicone is then poured over the master pattern and allowed to cure, solidifying into a durable yet pliable mold. Each step demands expert oversight, as even minor errors can lead to imperfections. This is why partnering with engineers who possess 15-25 years of hands-on expertise ensures that every silicon rubber mold is crafted to the highest standards of quality and dimensional accuracy.

Partnering with Experts for Custom Molding Solutions

While the material is important, the ultimate success of a project often hinges on the expertise of the manufacturing partner. At Guangdong Engineering Plastics Industries Group Co., Ltd., our team of senior engineers leverages decades of experience to provide personalized customization and comprehensive research and development services. Our deep-rooted knowledge in a wide array of engineering plastics like PEEK, PPS, and Nylon informs our holistic approach to manufacturing challenges, allowing us to design and execute solutions for even the most demanding applications. This engineering prowess is directly applicable to creating a superior SILICON MOLD that meets your exact specifications. Our commitment to excellence has enabled us to serve a global clientele, exporting precision components to the USA, UK, Canada, and Germany, and solidifying our reputation as a trusted international partner.

Choosing the Right Partner for Your Molding Needs

Ultimately, selecting the right manufacturing partner is crucial for achieving your project goals. The benefits of silicone molding—from rapid iteration to cost-effective small-batch production—are best realized when supported by a team that combines technical skill with a commitment to quality. Whether your project involves a custom-designed seal, a complex gear, or a specialized component made using a state-of-the-art mold, leaning on a company with a proven track record is the key to success. By prioritizing comprehensive design, research, and development, we ensure that every product, from concept to completion, meets the rigorous demands of today's competitive global market.