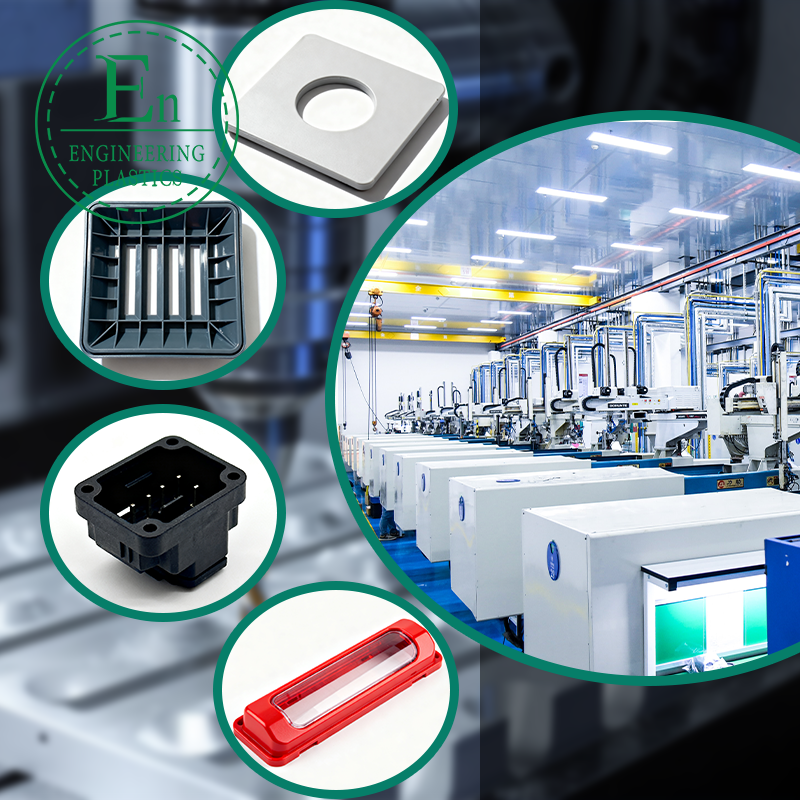

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

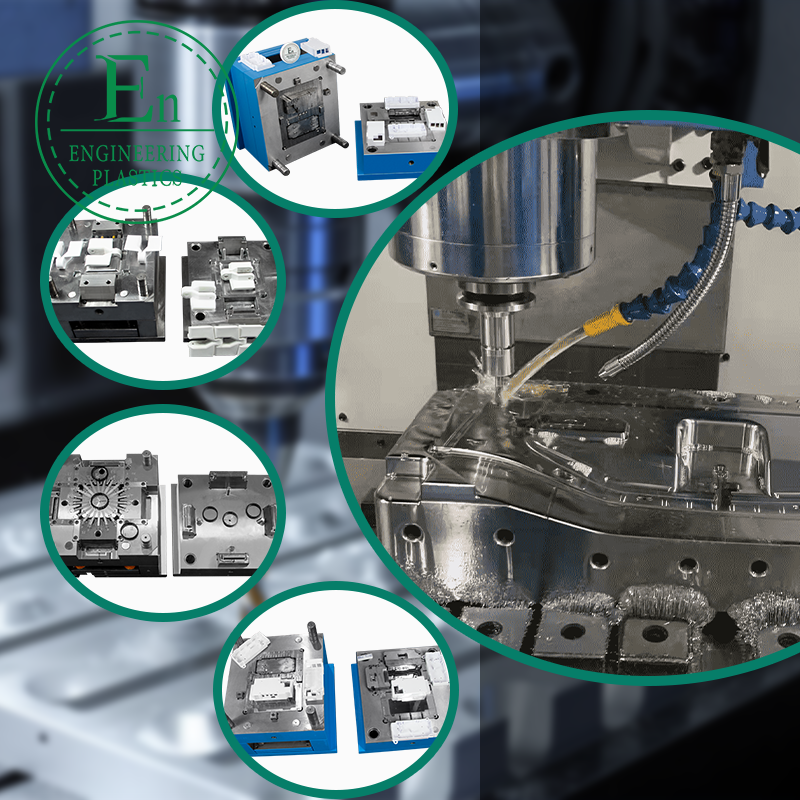

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Understanding Plastic Components

Plastic components play a critical role in modern manufacturing due to their versatility and wide range of applications. From simple plastic gears to complex sealing rings, their usage spans across industries. Companies like Guangzhou Encinial Specialty Plastics Co., Ltd. have excelled in customizing plastic engineering products, catering to a diverse clientele. Their expertise and dedication help businesses worldwide obtain high-quality plastic components tailored to their specific needs.

The Importance of Plastic Custom Parts in Manufacturing

In the realm of manufacturing, plastic custom parts are indispensable. They offer an array of benefits including lightweight, durability, and cost efficiency. Guangzhou Encinial Specialty Plastics, equipped with advanced CNC forming machines and laser cutting technology, enhances the precision and quality of tailored plastic components. With over 26 years in the industry, their seasoned engineers are adept at producing specialized components that meet specific client demands, whilst employing materials such as PEEK, PPS, and nylon.

Innovative Plastic Design Techniques

Plastic design is increasingly becoming a focal point in product development. The ability to creatively and precisely design plastic components presents opportunities for innovation. At Guangzhou Encinial Specialty Plastics, the design process is a collaborative effort between experienced engineers and the latest technology, ensuring each product not only meets but exceeds industry standards. The successful export of their custom-designed plastic products to countries like the USA, UK, and Germany, speaks volumes about their global reputation and commitment to excellence.

Global Reach and Expertise of Guangzhou Encinial Specialty Plastics Co., Ltd.

With an impressive factory space of 10,000 square meters located in Guangzhou, the company serves a vast international market including the Middle East and Singapore. Their strategic approach, paired with a dedicated team of experts, fosters innovation in plastic engineering. As a testament to their global reach, they have established a strong presence in exporting custom-engineered plastic products worldwide, proving their commitment to quality and customer satisfaction through industry-leading services.