Introduction: Understanding Automotive Mold

Automotive mold plays a pivotal role in the mass production and precise manufacturing of automotive components. This essential tool is used to shape and form materials through processes such as automotive injection molding, enabling manufacturers to create parts that meet stringent quality and safety standards. As the automotive industry evolves, so does the technology and craftsmanship involved in automotive mold manufacturing.

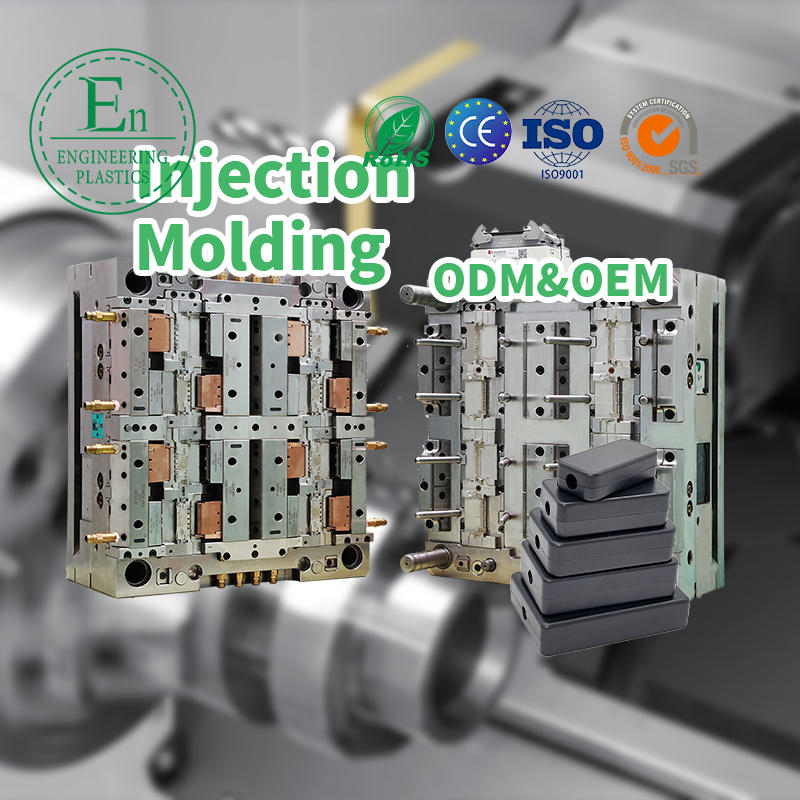

The Importance of Automotive Injection Molding

Automotive injection molding is a specialized process in which plastic or other material is melted and injected into a mold cavity to produce intricate and high-quality parts. The process ensures strength, durability, and the defined features required for automotive components. This technique is particularly advantageous for producing lightweight parts without compromising their structural integrity, easing vehicle performance.

For instance, automotive injection molding is widely employed in the production of dashboards, bumpers, or other aesthetic and functional elements. The key lies in the precision and reliability that a well-designed automotive mold delivers during production, ensuring that every part conforms to strict specifications. This method not only reduces manufacturing costs but also increases efficiency, making it a preferred choice for automakers.

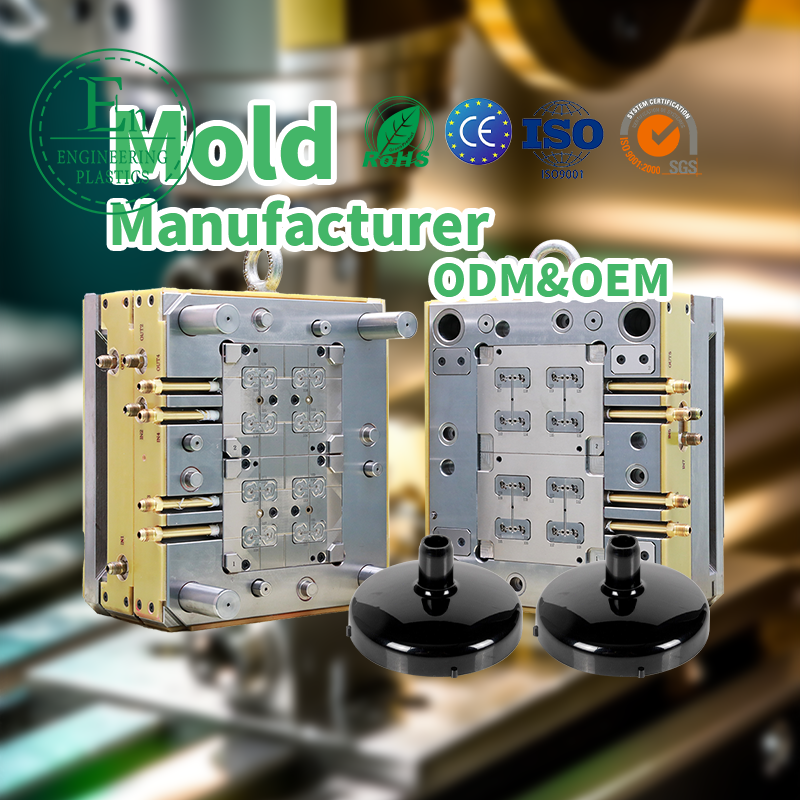

Case Study: Advancements in Automotive Mold Manufacturing

The rapid advancements in automotive mold manufacturing have revolutionized the way components are produced. A fascinating example can be observed in how a leading automobile manufacturer successfully optimized their mold design to improve production efficiency and reduce waste. By adopting Computer-Aided Design (CAD) tools and incorporating simulation technologies, they achieved highly precise molds that minimized errors during production.

Additionally, this case illustrates the importance of selecting the right materials for mold construction. High-grade steel and aluminum are often chosen for their durability, ensuring that the mold can withstand repeated use and high-pressure injection. The innovative approach resulted in better cost management, improved product quality, and faster time-to-market – all crucial factors in the competitive automotive landscape.

Future Considerations in Automotive Mold

As the automotive industry continues its transition toward electric vehicles (EVs) and increased sustainability, the role of automotive mold manufacturing will expand even further. The emphasis will shift to creating molds for lightweight, energy-efficient components, addressing both structural and environmental requirements. Incorporating smart technologies such as IoT-enabled molds and advanced monitoring systems will further streamline production processes.

Another critical area is evolving material science. The integration of recyclable and eco-friendly compounds into mold designs will play a vital role in reducing the industry's carbon footprint. These advancements demonstrate the scope and significance of automotive molds in shaping the future of mobility, showcasing their impact on innovation and sustainability.

Conclusion

Automotive mold is undeniably a cornerstone of modern vehicle manufacturing. From automotive injection molding to cutting-edge mold manufacturing techniques, this tool has set benchmarks for quality, efficiency, and innovation. As demonstrated in real-world cases and trends, the future of automotive mold lies in its adaptability and technological progression, reflecting its continual evolution alongside the demands of the automotive sector.