Designer Molds: Revolutionizing Quality and Precision

Designer molds have become a cornerstone in industries ranging from manufacturing to artisan crafts. Whether you're a business aiming to produce high-precision components or a creator looking to bring bold designs to life, designer molds streamline the process and ensure consistency in production. But what makes them indispensable? The answer lies in their capability to meet growing demands for customization, efficiency, and reliability, especially as industries evolve.

The Problem with Traditional Mold-Making Techniques

Traditional mold-making techniques often fail to cater to modern-day requirements. The lack of precision, limited design flexibility, and time-intensive processes often leave businesses struggling to meet quality standards. In some cases, compromises in mold quality can lead to defects in finished products, which not only incur extra financial costs but also damage customer trust. Smaller, artisan-based businesses suffer the most, as they tend to lack resources to afford heavy-duty machinery or intricate design systems.

Custom Mold Design: A Tailored Solution

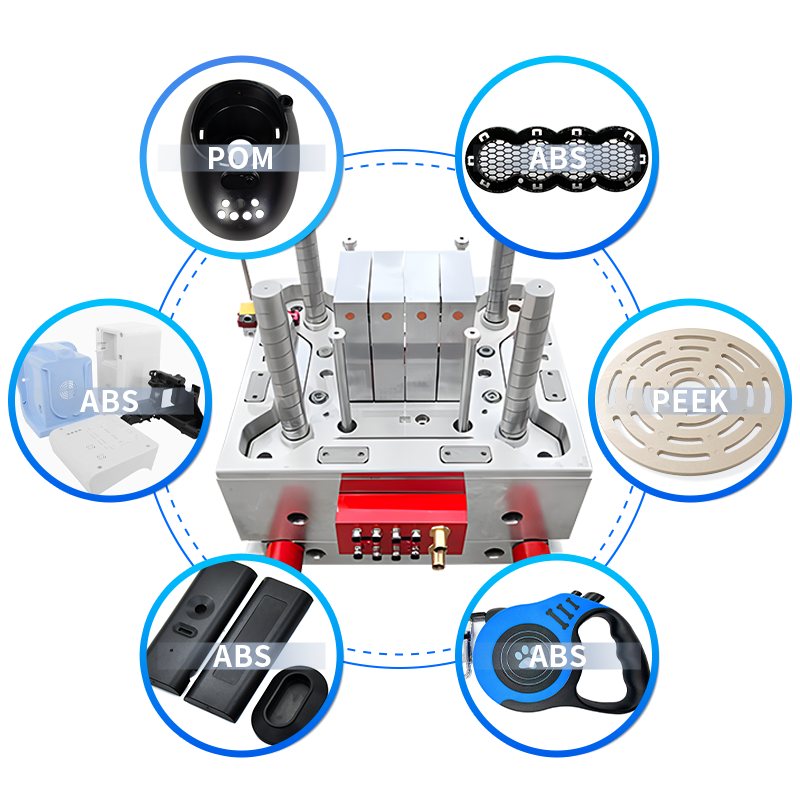

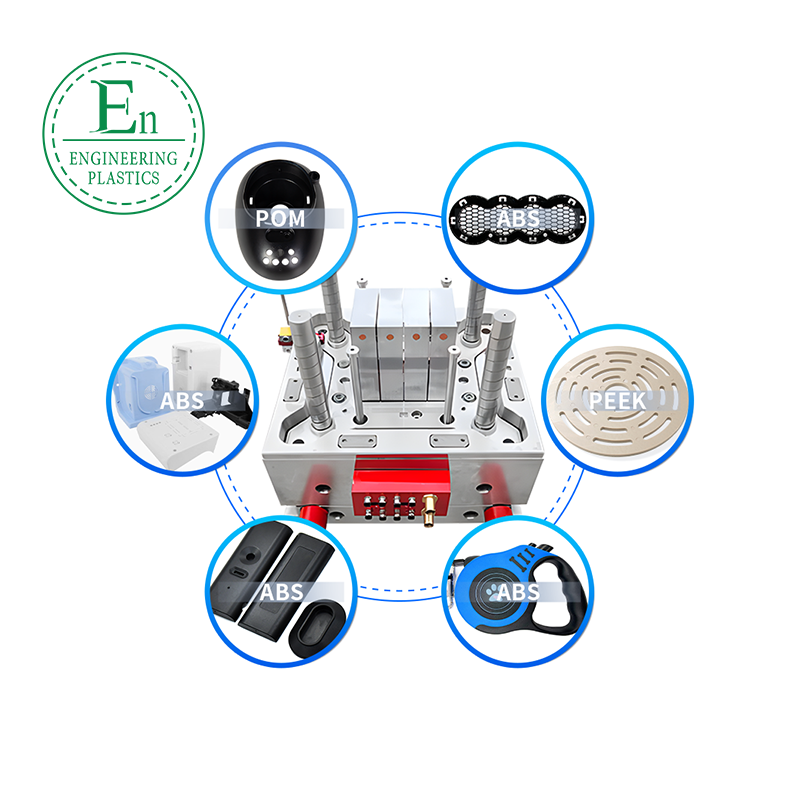

Custom mold design acts as a perfect solution to address these challenges. With tailored molds, businesses and creators alike gain the ability to create unique designs that resonate with their specific needs. Whether it’s intricate detailing or precise dimensions, custom mold design opens avenues for innovation while maintaining high levels of accuracy. Advances in design-making technologies such as CAD software further simplify the process, enabling mold creators to visualize and modify their designs before production.

The Rise of Design Makers in Modern Manufacturing

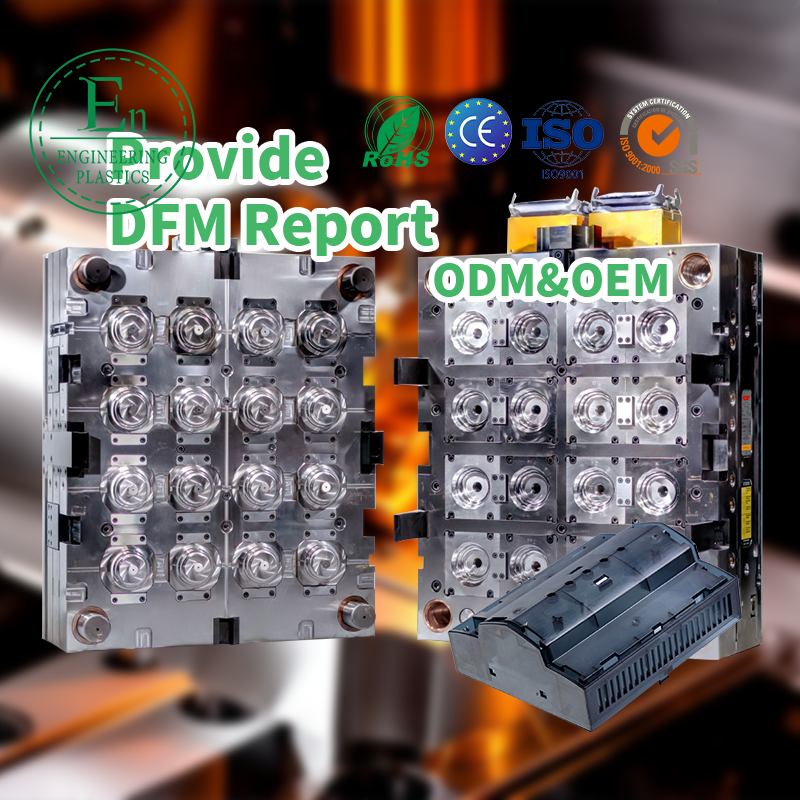

The demand for designer molds has propelled the rise of design makers – professionals and companies specializing in mold creation. Design makers bring expertise to the table, ensuring both small-scale and large-scale operations can benefit from customized solutions. Their services make it possible for businesses to produce molds in a cost-effective manner without sacrificing quality. Collaborative efforts between businesses and design makers allow for the realization of ambitious projects while keeping production timelines intact.

Leveraging Designer Molds Across Industries

Industries such as automotive, construction, consumer goods, and even fine arts have embraced designer molds to improve product aesthetics and functionality. Whether it’s crafting intricate architectural elements or providing parts for machinery, designer molds help achieve precision. For entrepreneurs seeking innovative product designs or businesses wanting to enhance end-user satisfaction, investing in designer molds is not just practical but essential.

Conclusion

Designer molds are reshaping how industries approach manufacturing and creation. By addressing the pitfalls of traditional mold-making techniques and offering solutions through custom mold design, businesses and creators can ensure they deliver high-quality, unique results. The rise of design makers has further simplified access to these solutions, enabling innovations across diverse fields. If you're looking to enhance your production process or bring your ideas to life, consider the transformative potential of designer molds.