We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

What is Custom Injection Molding?

Custom injection molding is a process that revolutionizes the way plastic products are manufactured. By injecting molten plastic into a custom-built mold, manufacturers create highly precise, durable, and functional plastic parts tailored to specific needs. This advanced method allows for personalized designs and ensures that products meet stringent quality standards, making it an ideal choice for businesses across various industries.

The appeal of custom injection molding lies in its versatility. Whether you need small-scale prototypes or large production runs, this technique delivers unparalleled consistency. Unlike standard manufacturing processes, custom injection molding guarantees that every part is identical, regardless of whether you need ten units or ten thousand. Businesses looking to stand out can leverage this method to achieve unique designs and meet exacting specifications.

The Benefits of Injection Molded Plastic Parts

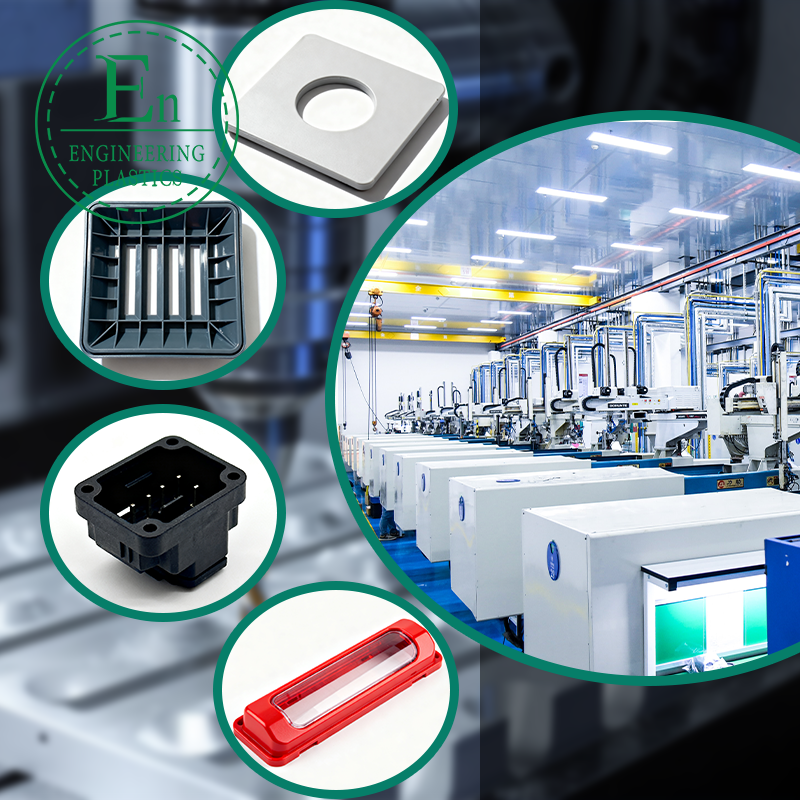

Injection molded plastic parts are essential components in countless industries, ranging from automotive and consumer goods to medical equipment and electronics. The superior quality, durability, and precision offered by this manufacturing process make these parts indispensable in demanding scenarios.

One significant advantage of injection molded plastic parts is their cost efficiency. By streamlining production, manufacturers can reduce both material waste and labor costs. This is particularly beneficial for industries requiring high-volume production of intricate components. Additionally, the ability to incorporate complex designs into a single mold saves time and resources during assembly.

These parts also offer noteworthy advantages in terms of material flexibility. Depending on the application, manufacturers can customize the plastic’s properties—such as heat resistance, strength, or lightweight characteristics—to meet the specific needs of the end product. The adaptability and reliability of injection molded plastic parts make them a critical asset for any modern manufacturing process.

Why Plastic Mold Manufacturing is the Key to Success

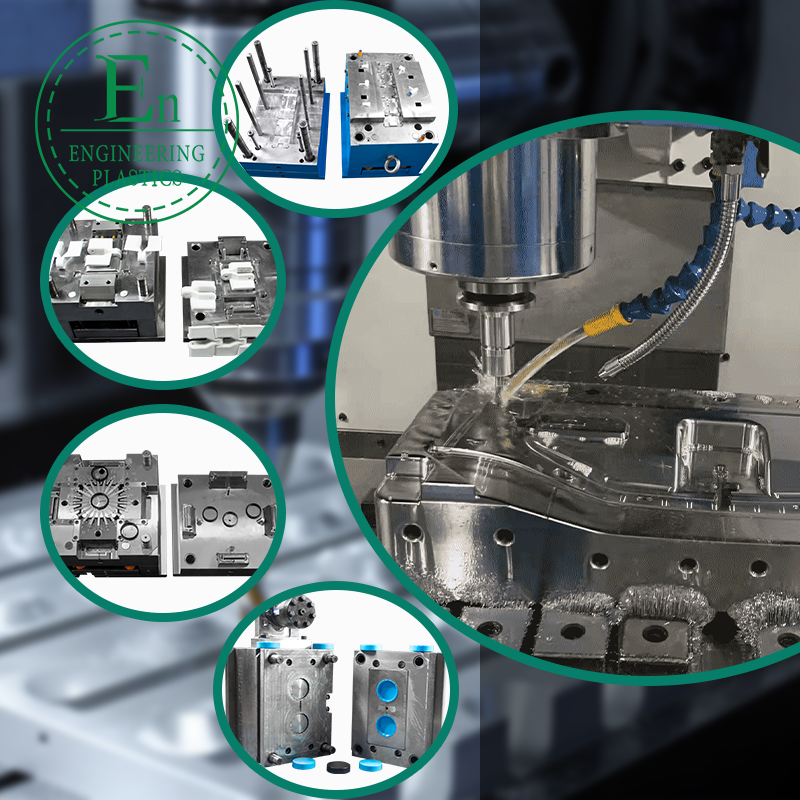

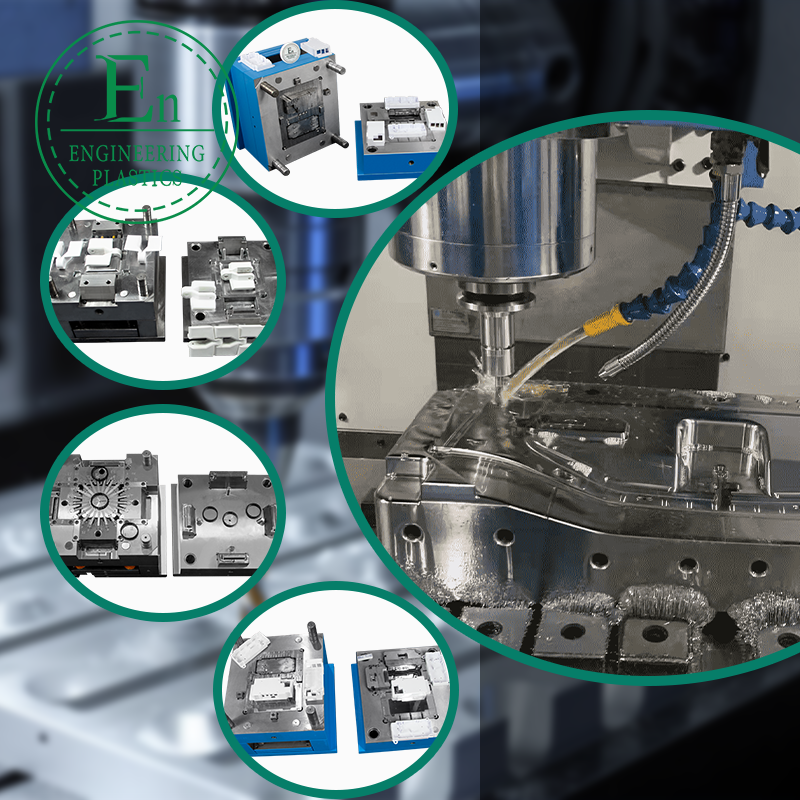

Plastic mold manufacturing is the backbone of custom injection molding. This process involves designing and crafting the molds used to produce injection molded parts. The precision and quality of these molds directly impact the performance and appearance of the final products.

Investing in high-quality plastic mold manufacturing ensures superior results. Advanced computer-aided design (CAD) and machining techniques are employed to create molds that replicate even the most intricate designs. These molds can withstand the pressures of high-volume production, maintaining consistency over time.

Moreover, the adaptability of plastic mold manufacturing allows for seamless modifications. Businesses can easily update their designs or introduce new features without starting from scratch. This flexibility is critical in fast-paced industries where market demands and product requirements shift rapidly. With expertly crafted molds, companies position themselves to stay ahead of the competition and meet customer expectations.

Conclusion

Custom injection molding, coupled with robust plastic mold manufacturing, is a game-changer for businesses needing high-quality, dependable, and bespoke plastic components. By leveraging these cutting-edge methods, companies can achieve unparalleled precision, efficiency, and adaptability. Whether you’re creating intricate injection molded plastic parts for high-tech industries or producing durable designs for everyday products, embracing custom injection molding processes will undoubtedly contribute to your long-term success.