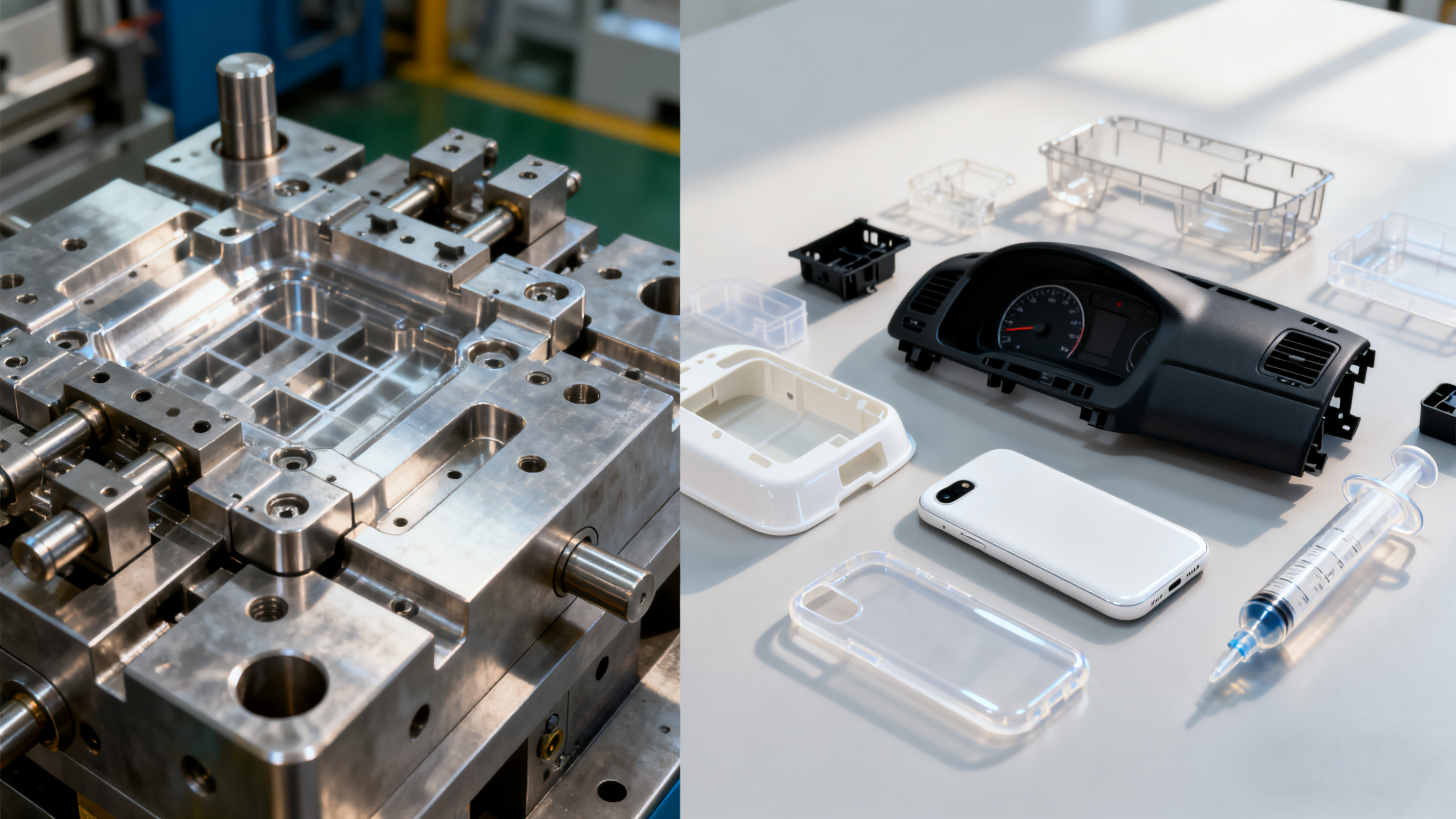

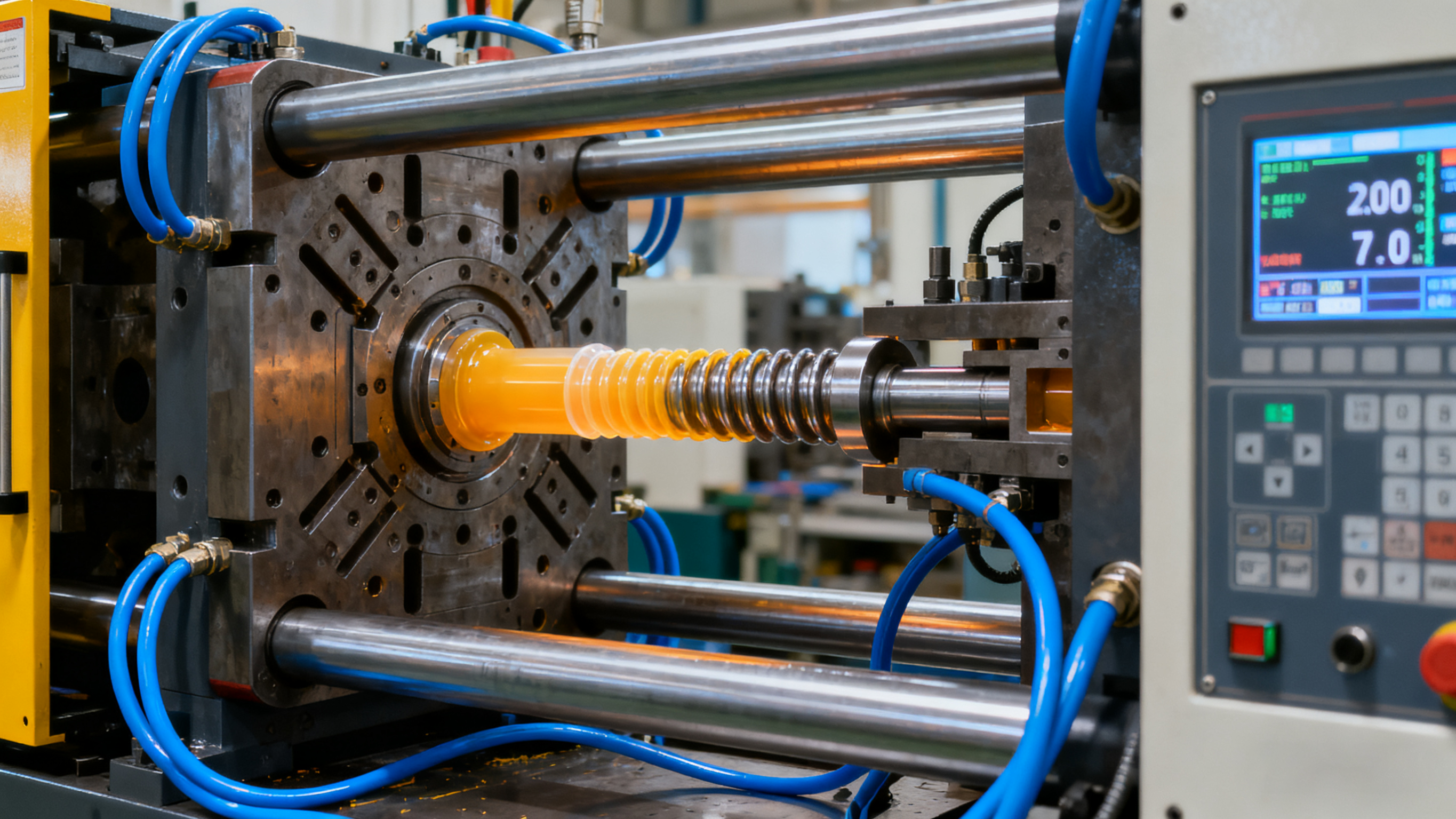

Bringing a product from concept to a tangible reality is a complex journey, and a critical step in this process is finding a reliable custom injection molding manufacturer. This foundational choice directly influences the quality, cost-effectiveness, and ultimate success of your product in the market. For businesses in industries ranging from automotive and aerospace to medical devices and consumer electronics, partnering with the right manufacturing expert is not just a logistical decision; it is a strategic one that can define a product's lifecycle and a company's reputation.

Understanding OEM and its Advantages

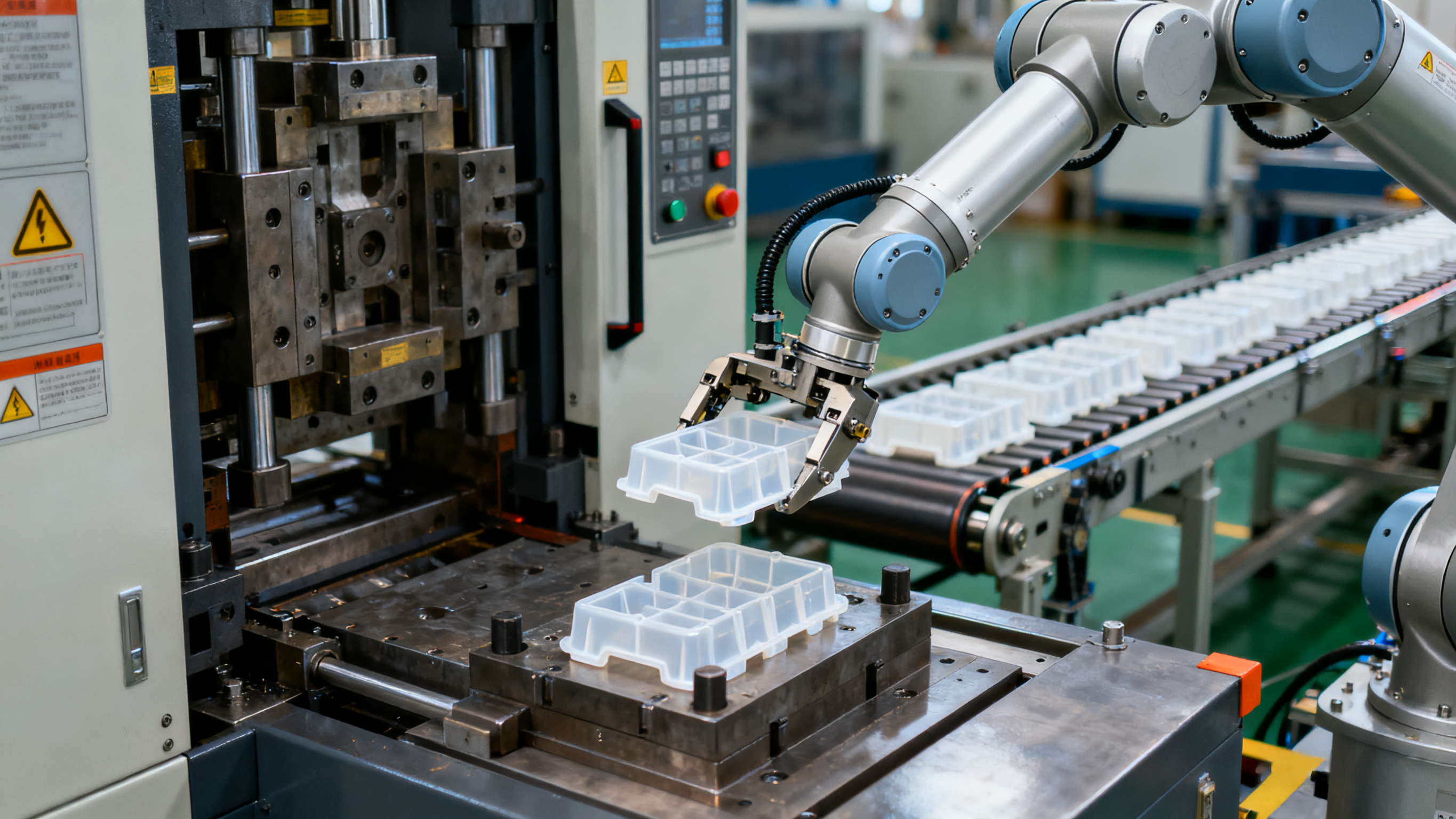

When exploring manufacturing partnerships, you will often encounter the term OEM, which stands for Original Equipment Manufacturer. An OEM plastic molding supplier specializes in producing parts, components, or entire products according to the exact designs and specifications provided by their client. This model is perfectly suited for companies that have a fully developed product design and require a skilled partner to handle the production phase with precision. The primary benefits of working with an OEM partner include maintaining complete control over your intellectual property, ensuring strict adherence to your quality standards, and leveraging specialized manufacturing capabilities without the need for significant capital investment in equipment and facilities. A dependable OEM plastic molding supplier acts as an extension of your own team, transforming your blueprints into high-quality physical products efficiently and consistently.

Leveraging ODM for Innovation and Design

For companies seeking a more comprehensive partnership, an ODM engineering plastic factory offers an enhanced level of service. ODM, or Original Design Manufacturer, means the supplier is involved in the design, research, and development processes in addition to manufacturing. This collaborative approach is invaluable for businesses that have a great idea but need technical expertise to refine it, optimize it for manufacturing, or even develop it from scratch. At Guangdong Engineering Plastics Industries Group Co., Ltd., our team of senior engineers with 15 to 25 years of expertise excels in this role. We provide comprehensive design and R&D support, offering crucial insights into material selection—from PEEK and PPS to Nylon and ABS—and ensuring the final design is optimized for performance and durability. An experienced ODM engineering plastic factory can help create sophisticated products like gears, pulleys, sealing rings, and bearings, turning a promising concept into a market-ready innovation.

Choosing the Right Custom Manufacturing Partner

The choice between an OEM or ODM model ultimately depends on your specific project requirements and internal capabilities. However, the most versatile and valuable partners are proficient in both. When you evaluate a potential custom injection molding manufacturer, look for key indicators of excellence. A proven track record, backed by deep engineering expertise, is non-negotiable. A company with decades of experience demonstrates an ability to navigate complex challenges and consistently deliver superior results. Furthermore, a manufacturer with a strong global footprint, evidenced by exports to demanding markets in the USA, UK, Canada, and Germany, confirms their commitment to meeting rigorous international standards. This global reputation is a clear sign that you are dealing with a trustworthy and highly capable OEM plastic molding supplier or ODM engineering plastic factory.

Your Partner in Precision Plastic Manufacturing

Ultimately, whether you need a dedicated producer for your established designs or a collaborative innovator to help engineer a new solution, selecting the right manufacturing partner is paramount. A firm that offers both OEM and ODM services provides the flexibility to support your project at any stage, ensuring a seamless journey from initial idea to final production. By partnering with an experienced company like Guangdong Engineering Plastics Industries Group Co., Ltd., you gain more than just a supplier; you gain access to a wealth of knowledge in materials science, product design, and advanced manufacturing techniques. This ensures your project is not just completed, but achieved with a level of excellence that sets you apart in the competitive marketplace.