Introduction to Titanium Machining Services

Titanium Machining Services are essential in industries where precision and strength are paramount. The durability and lightweight nature of titanium make it an ideal material for applications ranging from aerospace to medical devices. Understanding the intricacies involved in machining titanium is crucial for delivering high-quality components that meet rigorous standards.

Expertise in Aluminum and Abs Machining Services

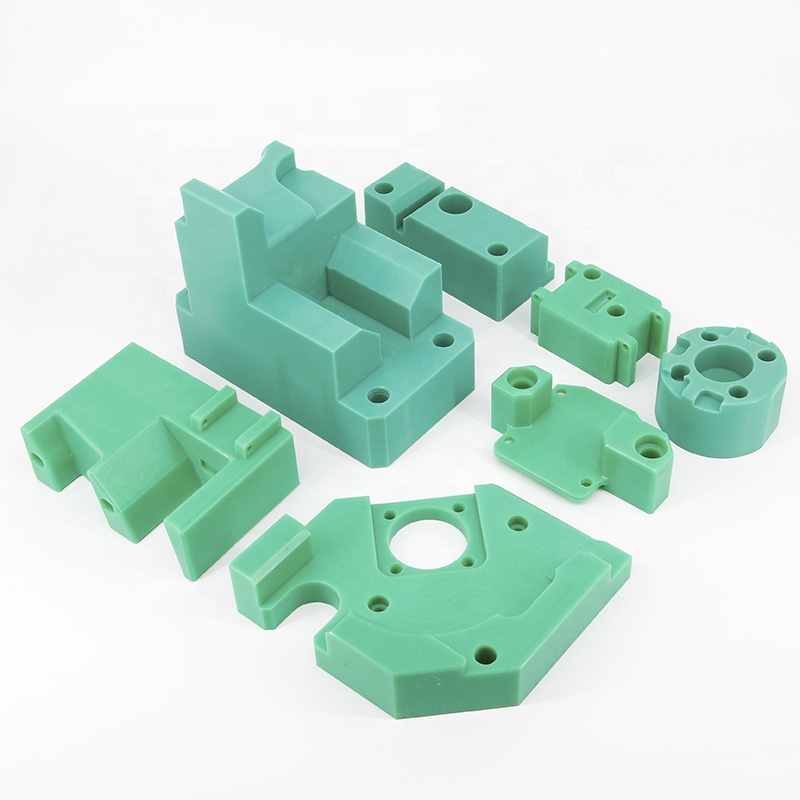

When it comes to Aluminum Machining Services, efficiency and precision are key. Aluminum is another material widely favored for its lightweight properties and excellent thermal conductivity, making it perfect for manufacturing components across various sectors such as automotive and electronics. Similarly, Abs Machining Services play a vital role in producing durable and impact-resistant plastic parts used in consumer products and industrial applications. Companies with expert knowledge in both aluminum and ABS machining can offer comprehensive solutions that cater to different material needs, ensuring optimal performance and high client satisfaction.

The Role of Guangdong Engineering Plastics Industries Group Co., Ltd.

Guangdong Engineering Plastics Industries Group Co., Ltd. stands out due to its team of senior engineers, each bringing 15-25 years of expertise to the table. This depth of experience enables the company to provide personalized customization alongside comprehensive design, research, and development services. Specializing in a broad array of engineering plastic products such as gears, pulleys, sealing rings, and bearings, this company excels in utilizing high-grade materials like PEEK, PPS, Nylon, ABS, and PTFE. They have built a significant presence both domestically and internationally, exporting products to the USA, UK, Canada, Germany, and other global markets. The company's reputation is forged on its ability to meet the specific requirements of diverse industries with precision-crafted solutions. Clients benefit from a long-standing commitment to quality, backed by robust development capabilities and a global reach.

Conclusion: Partnering for Success

In an ever-evolving industrial landscape, the capability to work seamlessly with materials like titanium, aluminum, and ABS is invaluable. Titanium Machining Services offer unmatched benefits for industries that cannot compromise on quality and reliability. Moreover, having a trustworthy partner like Guangdong Engineering Plastics Industries Group Co., Ltd. ensures that businesses receive the highest standards of engineering craftsmanship. By leveraging the expertise of a seasoned team and taking advantage of their adept skills in both metal and plastic machining, companies can push the boundaries of what's possible in product development and innovation. Whether developing cutting-edge technologies or enhancing existing solutions, collaborating with experienced providers of machining services becomes a strategic asset in achieving industrial excellence.