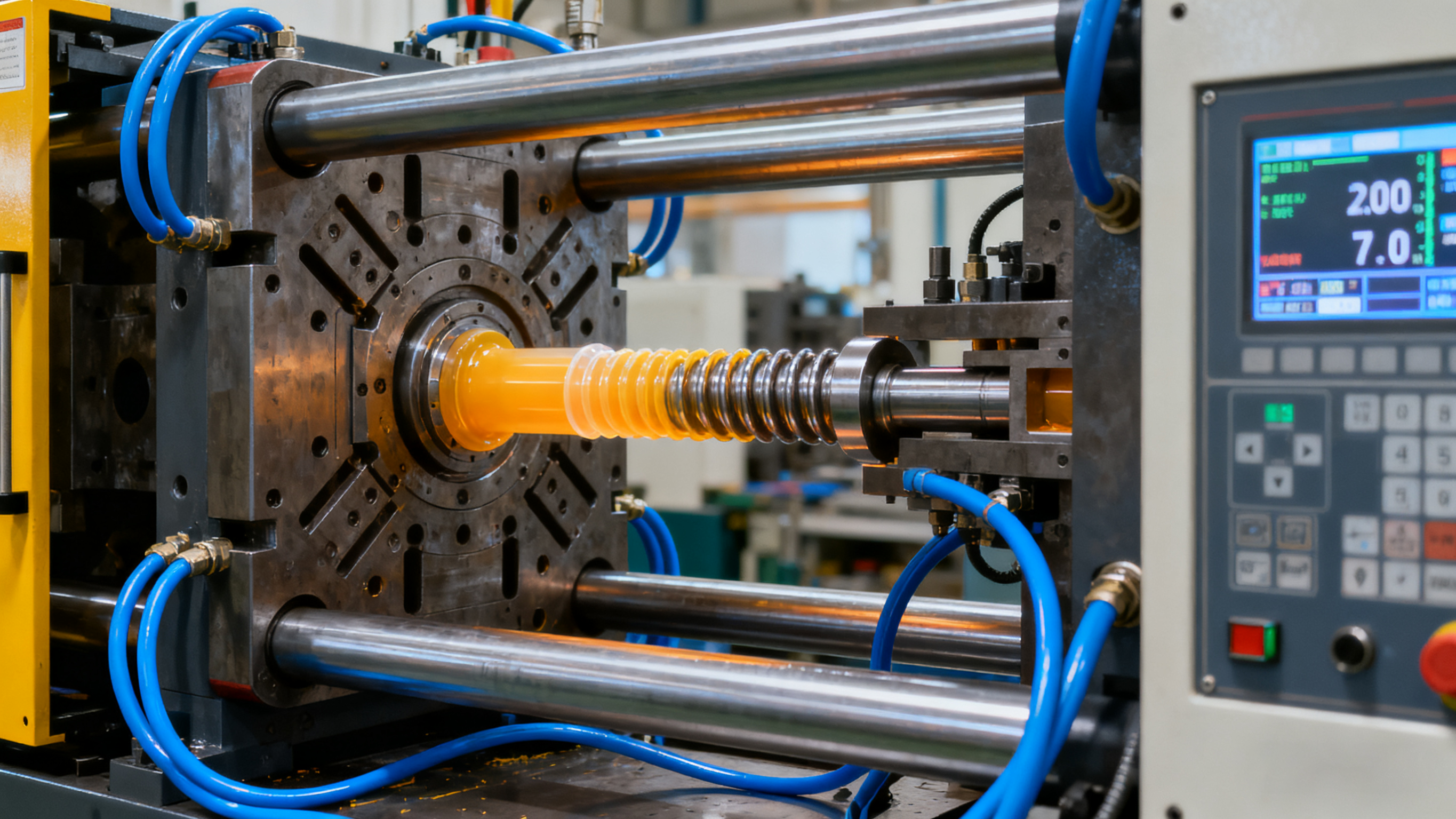

Injection molding silicone is a versatile and innovative process that has revolutionized the manufacturing industry, allowing for the production of high-quality, durable products with precision and efficiency. This technique involves injecting molten silicone material into a mold to create complex shapes and designs, making it ideal for applications in medical devices, automotive parts, and consumer goods. As a leading expert in this field, Guangdong Engineering Plastics Industries Group Co., Ltd. leverages its team of senior engineers with 15-25 years of expertise to deliver personalized customization and comprehensive design solutions. Our commitment to excellence ensures that every project meets the highest standards of quality and innovation, helping businesses worldwide achieve their manufacturing goals.

Understanding Injection Molding Design

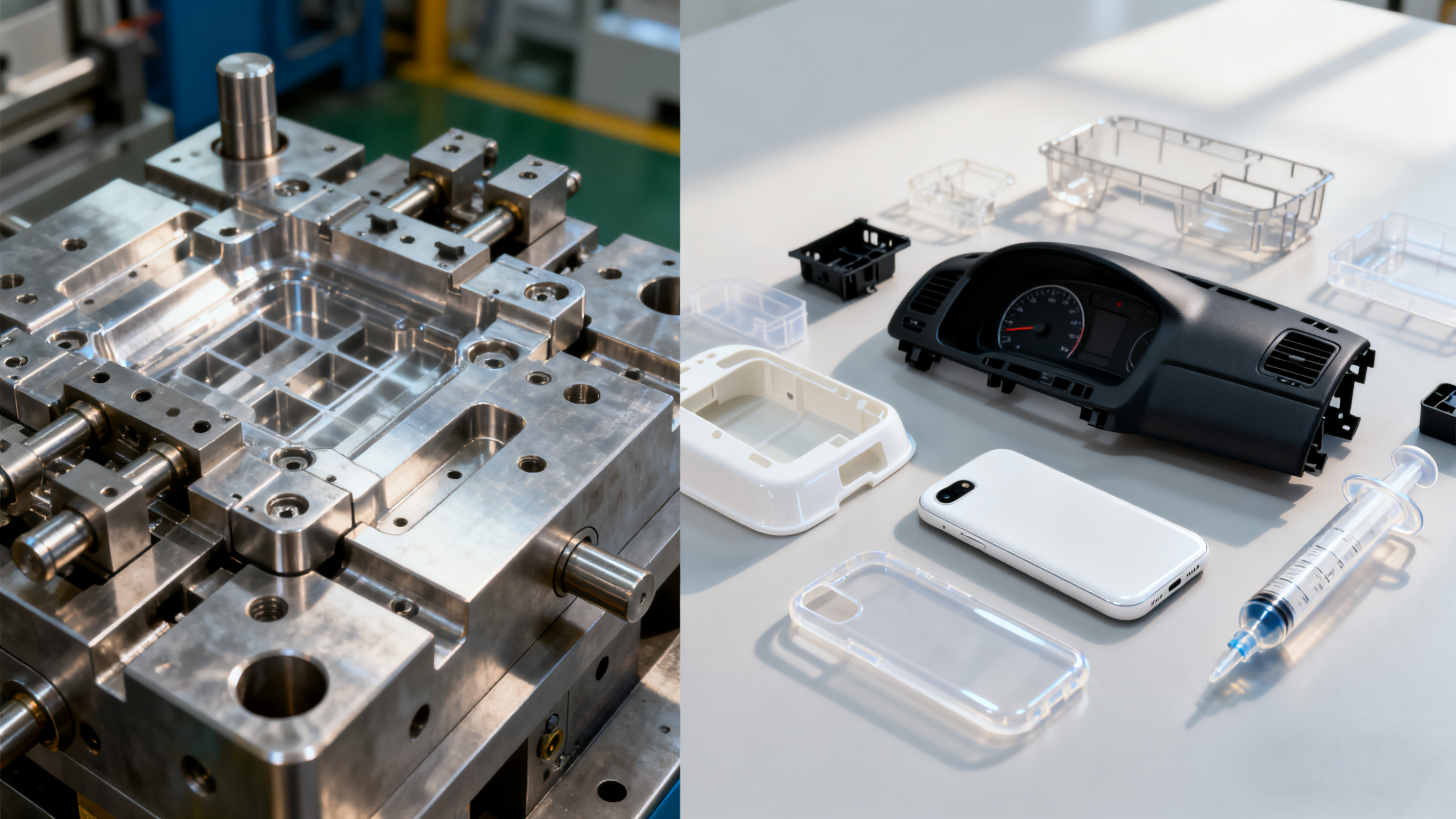

Injection molding design plays a crucial role in the success of silicone products, as it determines the functionality, aesthetics, and durability of the final item. Effective injection molding design involves careful consideration of factors such as material flow, cooling rates, and mold cavity details to minimize defects and optimize production. At Guangdong Engineering Plastics Industries Group Co., Ltd., our engineers specialize in injection molding design, utilizing advanced software and techniques to create custom solutions tailored to client needs. We manufacture a wide range of engineering plastic products, including gears and sealing rings, using materials like silicone, PEEK, and PTFE. This expertise allows us to address challenges in injection molding design, ensuring that products are not only functional but also cost-effective and scalable for various industries.

The Rise of Injection Moulding in the UK

Injection moulding UK has seen significant growth in recent years, driven by the demand for high-performance materials and sustainable manufacturing practices. This process is particularly popular in the UK for producing components in sectors like electronics, healthcare, and automotive, where precision and reliability are paramount. Guangdong Engineering Plastics Industries Group Co., Ltd. proudly serves international clients in the UK, exporting top-tier products that meet stringent regulatory standards. Our global reputation is built on our ability to offer comprehensive design, research, and development capabilities, blending injection molding silicone with other advanced materials to create innovative solutions. For instance, our sealing rings and bearings have been successfully implemented in UK-based projects, demonstrating the adaptability of injection moulding UK to local market needs.

Benefits and Applications of Injection Molding Silicone

One of the key benefits of injection molding silicone is its exceptional flexibility and resistance to extreme temperatures, making it suitable for a variety of demanding environments. This material's biocompatibility also makes it a top choice for medical applications, such as implants and tubing, where safety and performance are critical. At our company, we integrate injection molding design principles to enhance these benefits, ensuring that products like our custom pulleys and bearings perform reliably over time. Furthermore, injection moulding UK benefits from our extensive export network, reaching clients in the USA, Canada, and Germany, which allows for seamless collaboration and knowledge sharing. By focusing on sustainable practices, we help reduce waste in the manufacturing process, aligning with global environmental goals.

Innovations and Future Trends in Injection Molding

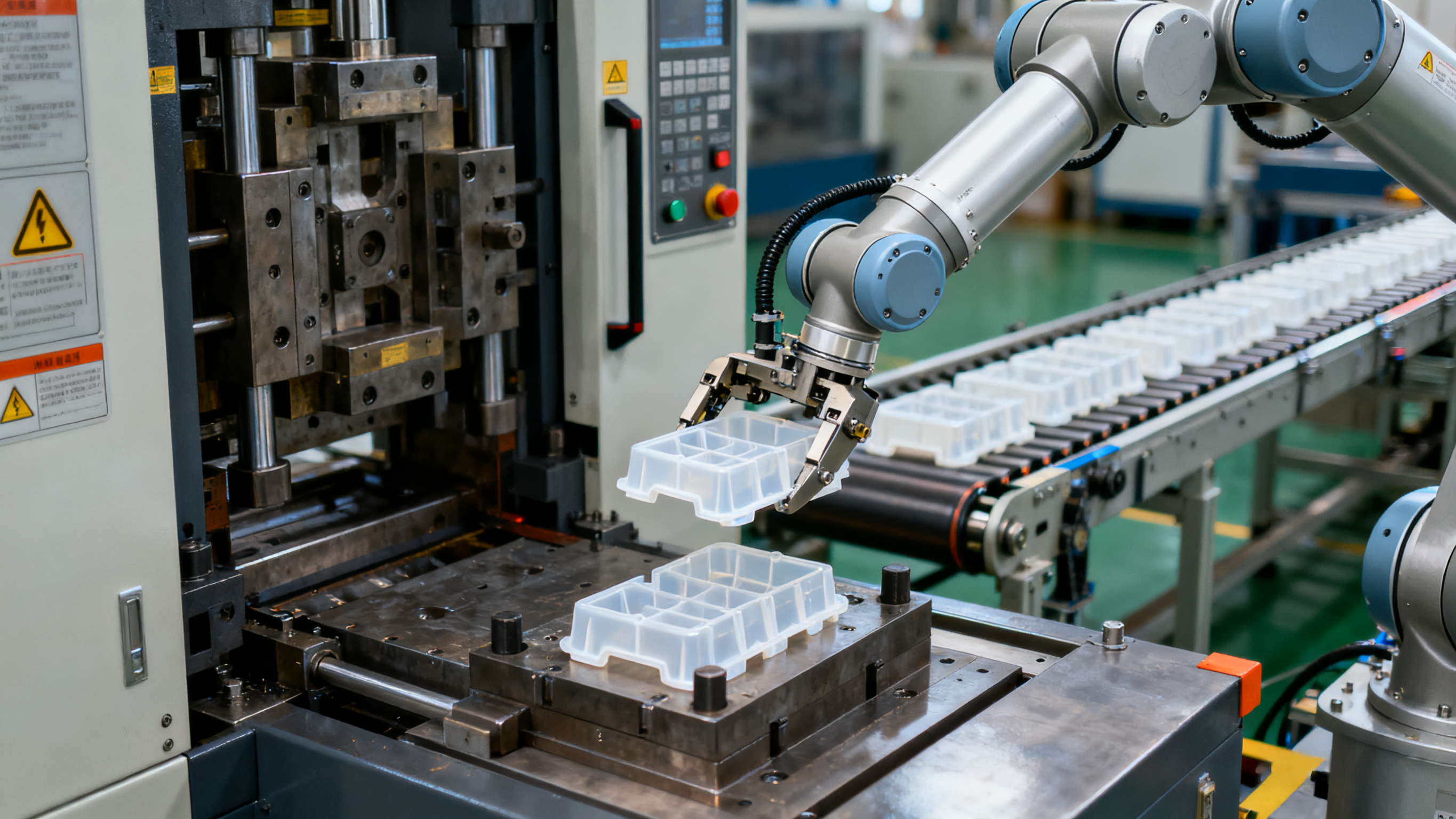

As technology advances, injection molding silicone continues to evolve with new innovations such as automation and 3D printing integration, which streamline production and reduce costs. This progression is evident in injection molding design, where computer-aided engineering tools enable more precise and efficient designs. Guangdong Engineering Plastics Industries Group Co., Ltd. stays at the forefront of these trends, investing in research and development to offer cutting-edge solutions for our clients. Our materials, including Nylon and ABS, complement silicone in various applications, expanding the possibilities for injection moulding UK and beyond. With our strong global presence, we're excited about future opportunities to collaborate on projects that drive industry progress, reinforcing our position as a trusted partner in engineering plastics.