Injection Mold Maintenance Services and Providers in the UK

Injection molding is widely used in the UK for automotive, medical devices, consumer electronics, packaging, and industrial parts. But production stability depends on an often overlooked asset: the injection mold. Professional injection mold maintenance keeps injection molding lines running with consistent quality, predictable cycle times, and fewer emergency stoppages.

In this guide, you will learn what UK manufacturers should expect from mold maintenance services, how to evaluate providers, what practical maintenance plans look like, and how global tooling partners can support UK and European production with measurable cost and downtime improvements.

Why Injection Mold Maintenance Matters in Injection Molding

An injection mold operates under high pressure, thermal cycling, and constant mechanical movement. Over thousands (or millions) of shots, small changes in surfaces, venting, cooling, and alignment can create outsized defects. A structured maintenance program protects your most valuable production tooling and reduces total cost of ownership.

Business and Quality Outcomes You Can Expect

- Longer mold life through controlled wear and corrosion prevention

- More consistent part dimensions and appearance across production batches

- Lower scrap rates by preventing flash, short shots, burn marks, and sink issues

- Less unplanned downtime and fewer costly rush repairs

- Better delivery performance for OEM and Tier suppliers with strict schedules

Common Mold Maintenance Problems in UK Production

Many UK injection molding operations run a mix of new and legacy tooling, sometimes across multiple facilities or subcontractors. These are the most common maintenance pain points that directly affect output and margins:

Aging Tooling and Hidden Wear

Legacy molds often accumulate gradual wear in parting lines, slides, lifters, and ejector systems. The result is progressive flashing, sticking, cosmetic marks, and dimensional drift that may be misdiagnosed as a machine or material problem.

Limited In-House Toolroom Capacity

Skilled mold technicians are hard to hire and retain. In-house teams often prioritize urgent production issues, leaving preventive work underfunded. This leads to a cycle of emergency repairs and repeat defects.

High Local Repair Costs and Long Lead Times

UK-based repair services can be excellent, but rates and scheduling can be challenging, especially for deep refurbishment, welding, high-polish finishing, or complex component replacements.

Downtime Risk on High-Cavity and Tight-Tolerance Molds

In multi-cavity molds, a single damaged cavity or cooling circuit can reduce output or force a shutdown. For medical, automotive, and precision components, the tolerance window is small and defect escape risk is high.

What Injection Mold Maintenance Services Typically Include

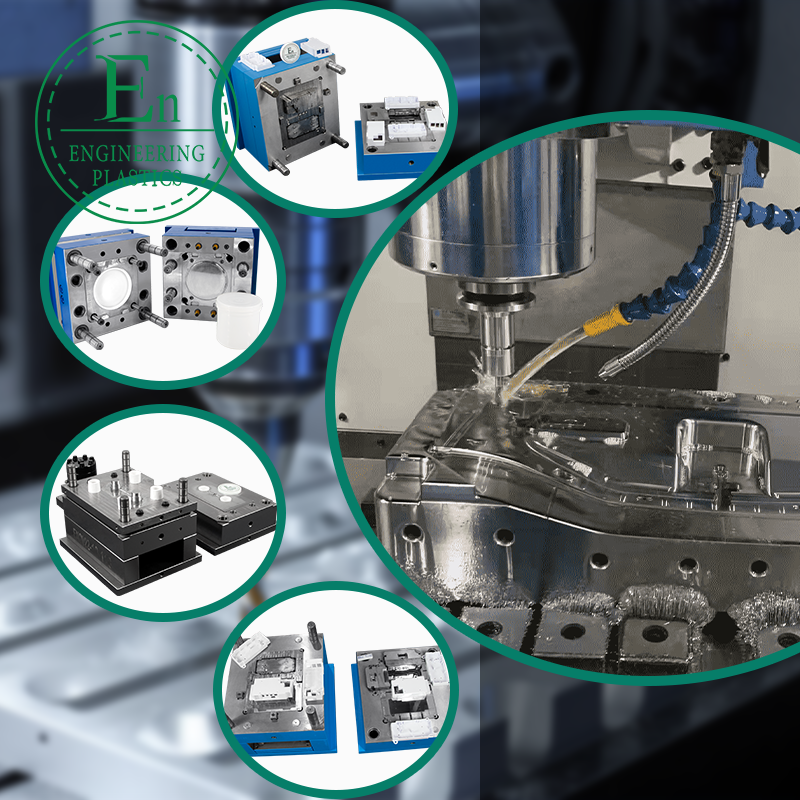

Maintenance providers in the UK generally offer three tiers of service. The best programs combine all three, matched to mold complexity, resin type, and production volume.

Preventive Maintenance

- Scheduled cleaning and inspection based on shot count and resin type

- Lubrication and functional checks for slides, lifters, and ejector assemblies

- Venting inspection and cleaning to prevent burns and short shots

- Cooling channel checks for blockage, scale, and flow imbalance

- Early identification of wear patterns and alignment changes

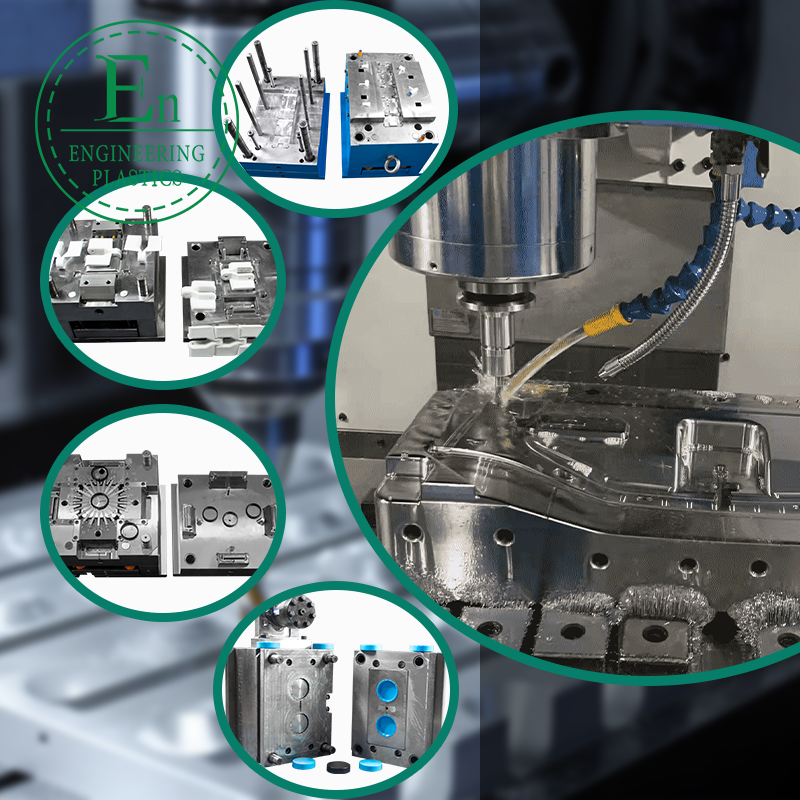

Corrective Maintenance and Repair

- Repair of parting lines, gates, runners, and shut-offs to reduce flash and burrs

- Replacement of worn components such as ejector pins, return pins, springs, and wear plates

- Welding, re-machining, and polishing of damaged cavities/cores

- Surface restoration and texture matching where required

- Root-cause analysis tying defects to tooling, process, and material conditions

Refurbishment and Optimization

- Cooling upgrades to reduce cycle time and stabilize warpage

- Venting upgrades to improve fill balance and cosmetic quality

- Steel and surface treatment selection for abrasive or corrosive resins

- Gate and runner optimization to reduce shear and improve consistency

- Documentation updates and standardized spare-part kits

How to Evaluate UK Mold Maintenance Providers

Selecting a mold maintenance provider is a risk decision. The wrong partner creates repeated problems and inconsistent results. Use the criteria below to compare suppliers for injection molding programs serving the UK, Europe, the US, and Russia.

Capability and Process Control Checklist

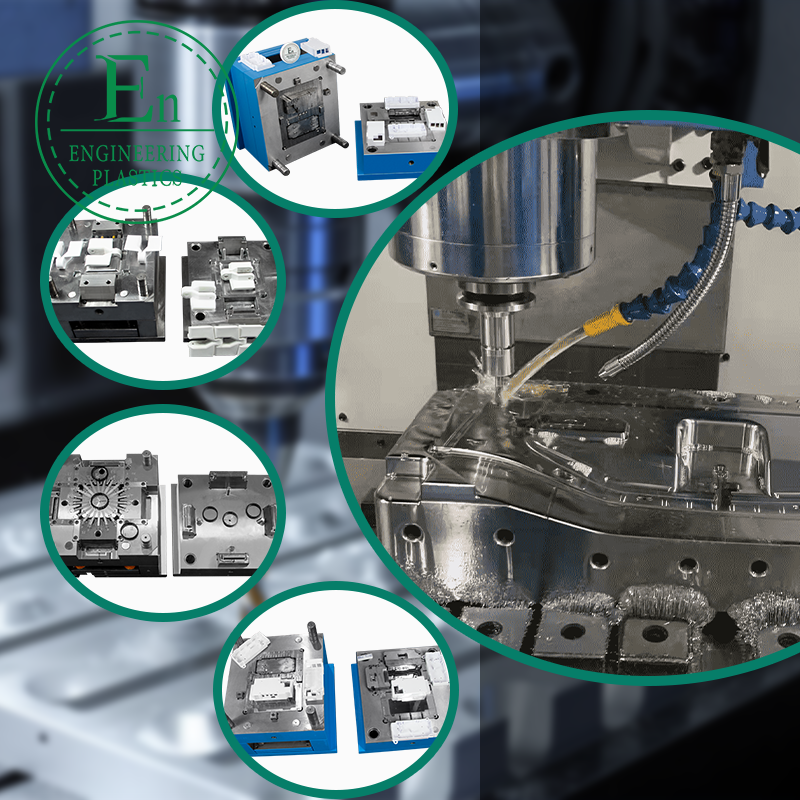

- Demonstrated experience with your mold type: multi-cavity, hot runner, unscrewing, two-shot, or insert molding

- Ability to measure and document: parting line condition, cavity wear, alignment, and critical dimensions

- Access to precision machining, welding, polishing, and texture repair when needed

- Clear preventive maintenance standards: what is checked, what is replaced, and how often

- Turnaround time and emergency response options, including spares strategy

- Transparent reporting with photos, findings, and recommended actions

- Experience meeting international customer requirements and audit expectations

Why Some UK Manufacturers Combine Local and Overseas Support

A growing number of manufacturers keep quick-response service local while using an overseas specialist for major refurbishment, component remanufacture, or full mold audits. This hybrid approach can reduce overall tooling spend while improving consistency.

When an International Partner Makes Sense

- Major refurbishment is needed (welding, re-machining, deep polishing, or cavity restoration)

- You want to standardize maintenance across multiple sites or subcontractors

- Spare parts are difficult to source or require custom remanufacture

- Cycle-time and defect improvements require tooling optimization, not just repair

- Cost pressure requires a lower total cost solution without sacrificing quality

Case Study: Reducing Flash and Downtime for a UK Automotive Program

A UK automotive supplier faced recurring flash and rising downtime on a 32-cavity injection mold for under-the-hood plastic components. Scrap rates were increasing, and emergency maintenance was becoming routine.

Challenges

- Progressive wear at shut-offs and parting line leading to flash

- Cooling imbalance causing warpage variation between cavities

- Limited in-house toolroom bandwidth for deep corrective work

- Customer pressure on delivery and consistent appearance

Solution

The program partnered with Guangdong Engineering Plastics Industrial Group Co., Ltd. for a full mold audit and refurbishment plan. The scope included parting line restoration, wear-component replacement, venting cleanup, and cooling-channel verification, with a documented maintenance standard for ongoing preventive work.

Results

- Reduced flash-related scrap through restored shut-offs and controlled alignment

- Improved stability across cavities by addressing cooling and venting issues

- Longer maintenance intervals and fewer emergency stoppages

- Lower total tooling cost through planned refurbishment instead of repeated urgent fixes

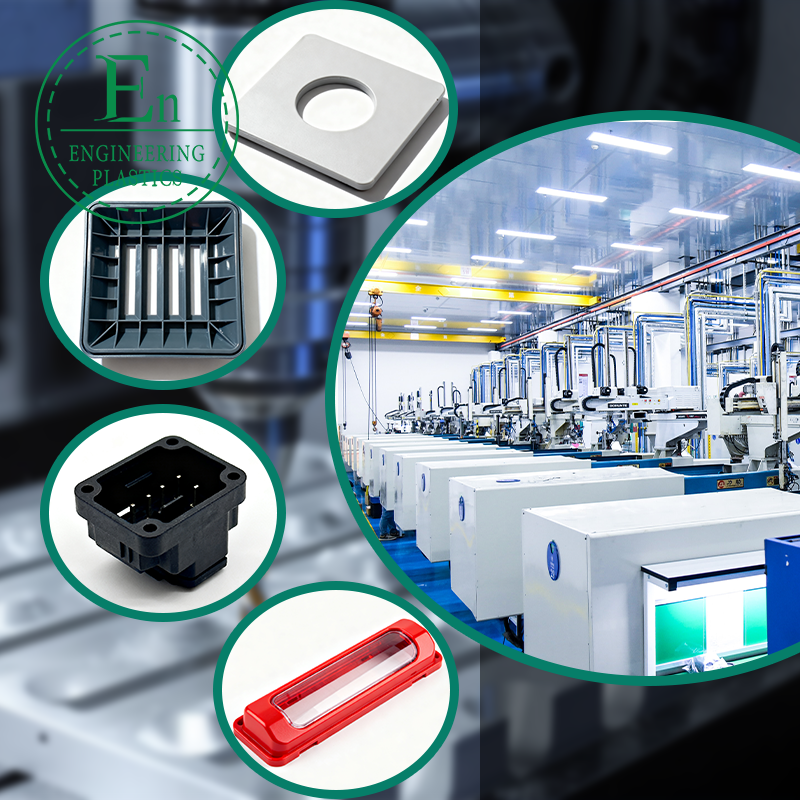

Guangdong Engineering Plastics Industrial Group Co., Ltd.: Your Global Tooling Partner

Guangdong Engineering Plastics Industrial Group Co., Ltd. supports international customers with injection molding and tooling solutions, including mold maintenance, refurbishment, and optimization for programs serving the UK, Europe, the United States, and Russia.

What We Deliver

- Injection mold design, manufacturing, and life-cycle maintenance support

- Refurbishment and life-extension services for precision molds

- Engineering plastics injection molding capability and process support

- Export-oriented project management with responsive communication

- Quality control aligned with B2B expectations for international supply chains

Practical Next Steps for Buyers

If you are sourcing injection mold maintenance in the UK or managing molds across multiple regions, start with a structured assessment. A good provider will ask for your shot counts, resin types, defect history, mold drawings, and critical-to-quality features.

Information to Prepare for a Fast Quote

- Mold type and cavity count, hot runner brand (if applicable), and material (e.g., P20, H13, S136)

- Current shot count and typical monthly volume

- Resins used (especially glass-filled, flame-retardant, or corrosive materials)

- Main defects and when they appear (start-up vs. steady-state)

- Expected turnaround time and whether spares are available

- Photos of wear areas, parting lines, gates, and ejector marks if possible

Conclusion and Purchase Motivation

Injection molding performance depends on mold condition. A proactive maintenance plan reduces scrap, protects delivery schedules, and extends the life of your tooling investment. If you are experiencing flash, downtime, inconsistent quality, or rising repair costs, now is the right time to evaluate a preventive program and a capable long-term provider.

Contact Us

Company: Guangdong Engineering Plastics Industrial Group Co., Ltd.

Website: https://www.gz-plastics.com/

Email: sales@gz-plastics.com

Content Action Form

Request Injection Mold Maintenance Consultation

Send us your mold details and defect photos, and we will respond with a maintenance plan and a commercial proposal tailored to your injection molding project.