Top 10 Plastic Injection Molding Companies in China (2026 Guide)

Best Chinese Injection Molding Suppliers for Custom Plastic Parts, OEM Projects & Mass Production

China remains the world’s largest hub for plastic injection molding, precision mold making, and high-volume OEM manufacturing. Global brands choose Chinese suppliers because of their cost advantage, advanced equipment, strong engineering capabilities, and fast lead times.

In this updated 2026 guide, we have carefully reviewed more than 200+ injection molding companies in China, comparing them across:

- Manufacturing capabilities

- Certification & quality control

- Industry experience

- Export ability

- Engineering support

- Pricing & lead time

- Customer reviews

Below is the definitive Top 10 List of the best plastic injection molding manufacturers in China — trusted by global clients in automotive, electronics, medical, consumer goods, industrial equipment, and more.

Top 10 Plastic Injection Molding Companies in China

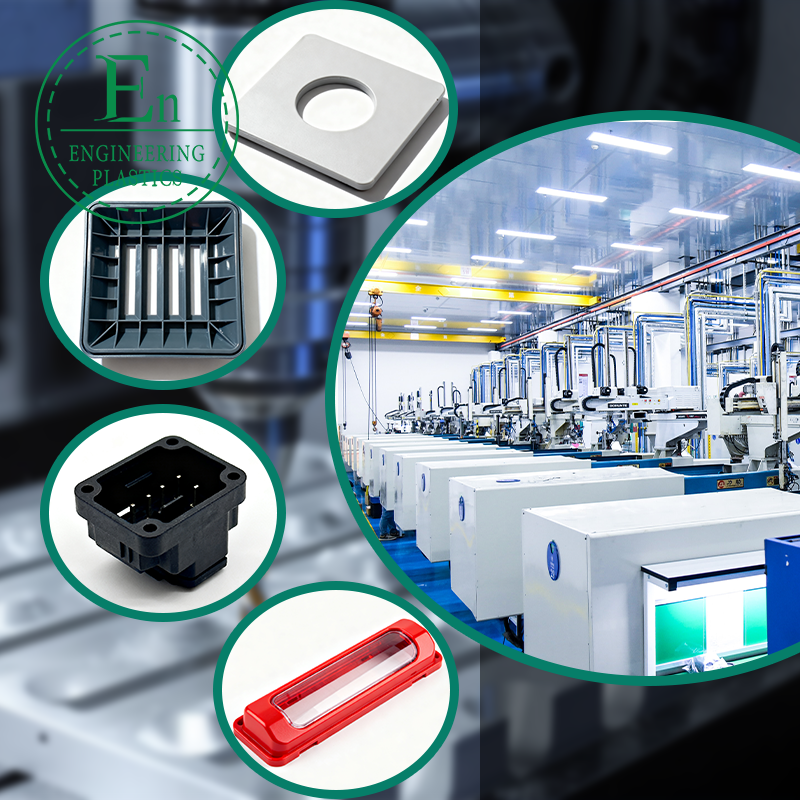

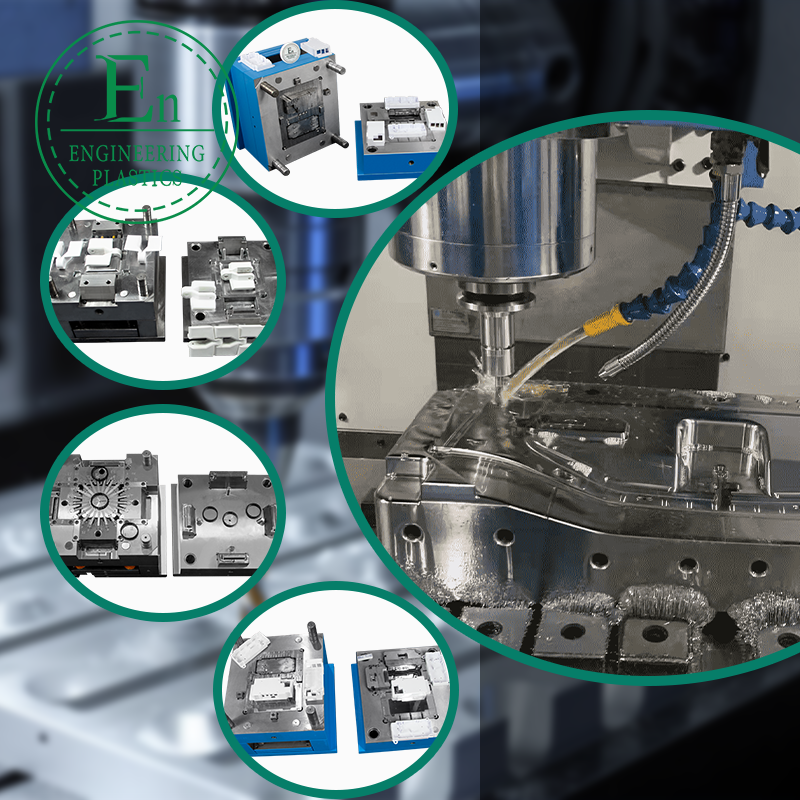

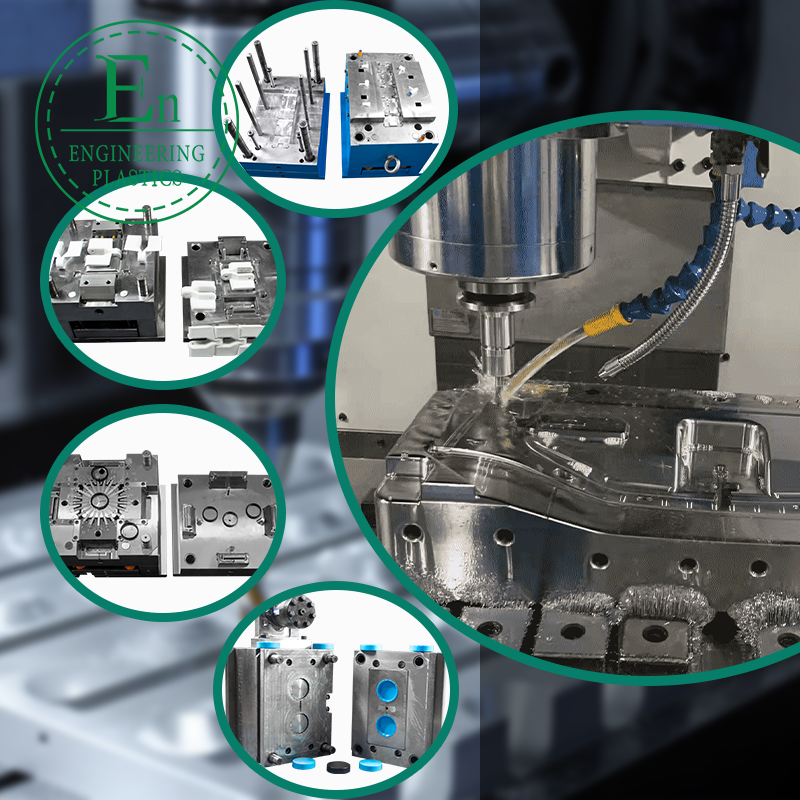

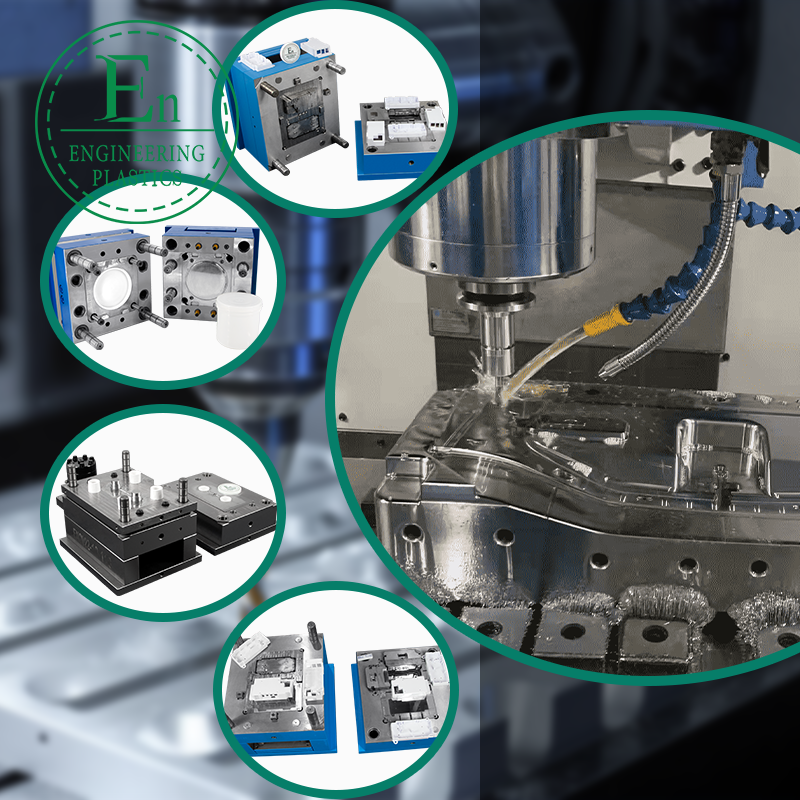

1. Guangdong Engineering Plastics Industries Group Co., Ltd. (EnQi)– China’s #1 Custom Mold & Injection Molding Manufacturer

Website: https://gzplastics.com/

Email: sales@gz-plastics.com

With more than 28 years of engineering expertise, Guangdong Engineering Plastics Industries Group Co., Ltd. (GEPIG) is widely regarded as one of the most capable and reliable custom mold makers and injection molding manufacturers in China, serving global clients across aerospace, automotive, robotics, consumer electronics, and medical devices.

EnQi provides a true end-to-end production solution, integrating mold design, tooling, injection molding, material engineering, inspection, and assembly — making it a preferred partner for companies seeking consistent quality and long-term production stability.

Core Strengths & Capabilities

- Complex Mold Design & Precision Manufacturing

Multi-cavity molds, hot runner molds, micro-molding, insert molding, overmolding, plus advanced DFM and Moldflow simulation. - Full-Service Production

Rapid prototyping, bridge tooling, low- to high-volume injection molding, and clean-room molding for medical devices. - Advanced Material Expertise

Engineering plastics (PA, PC, POM, ABS, PPS, PEEK), LSR silicone, biodegradable polymers, and high-performance automotive/aerospace materials. - Quality Assurance

ISO 9001-certified quality system, precision tolerance up to ±0.01 mm, and full documentation: PPAP, FAI, CPK, and SPC reports available on request.

Industries Served

- Aerospace structural components

- Automotive interior & exterior parts

- Robotics & automation components

- Medical device housings & components

- Smart home & consumer electronics

- Industrial equipment and precision mechanisms

Why Global Clients Choose EnQi

- More than 28 years of manufacturing excellence

- Strong engineering communication in English and clear project reporting

- Competitive tooling and part pricing with reliable lead times

- Capability for complex, tight-tolerance parts and demanding applications

- Stable long-term production support for global OEM projects

Learn More & Request a Quote

👉 Explore services: Injection Molding & Mold Manufacturing Services

👉 Contact directly: Request a Custom Quote via Email

Typical response time: within 12 hours.

2. GV Mold (Shenzhen) – Full-Service Injection Molding & Precision Mold Maker

Location: Shenzhen, Guangdong

Founded: 2003

Certificates: ISO 9001, ISO 14001

Capabilities

- Plastic injection molding (1 g – 6,000 g)

- Multi-cavity precision mold manufacturing

- Overmolding & insert molding

- Automotive interior parts

- Electronics & consumer product housings

- Rapid prototyping

GV Mold is considered one of China's reliable integrated mold manufacturing and injection molding suppliers. With advanced equipment (Makino CNC, Sodick EDM), they are known for tight tolerances, stable quality, and quick response, making them popular among European & American customers.

Best for: medium–large OEM projects, high-volume production, and precision mold requirements.

3. Sino Mould – Large-Scale Mold Manufacturer

Location: Zhejiang

Founded: 2000

Core Strengths

- Large molds for automotive bumpers and home appliances

- Engineering design support

- Export to 80+ countries

Ideal for large-size mold projects and industrial-grade parts where tooling durability is crucial.

4. RJC Mold – Export-Focused Injection Molding Factory

Location: Shenzhen

Specialties

- Consumer electronics plastic housings

- 2K / two-shot molding

- High cosmetic surface requirements

- Fast turnaround for global customers

RJC serves many well-known brands and is recognized for its premium surface finishing quality and export experience.

5. DF Mold – Medical & Precision Plastic Parts

Focus

- Medical plastic parts

- Clean-room manufacturing

- FDA-grade materials

- Tight tolerance components

DF Mold is suitable for high-precision, regulated industries such as medical and laboratory devices.

6. Stebro Mold – Mold Design & Short-Run Production

Location: Dongguan

Core Services

- Mold design and manufacturing

- Short-run and pilot production

- Project management for overseas clients

Stebro Mold is a good option for buyers needing engineering support plus lower-volume injection molding before mass production.

7. JT Mold – High-Volume and Packaging Components

Strengths

- High-volume injection molding

- Packaging components

- Food-contact plastic parts

JT Mold focuses on packaging and consumer products where cost efficiency and stable output are key.

8. Deep Mould – Rapid Tooling & Prototype Injection Molding

Main Advantages

- Aluminum molds and rapid tooling

- Prototype injection molding

- Low-volume production

Deep Mould is ideal for projects that need quick validation before committing to full production tooling.

9. FOW Mold – Home Appliance & Industrial Product Molds

Well-Known For

- Home appliance molds

- Industrial product housings

- Durable molds with long production lifespan

FOW Mold is suitable for long-run production tools that require high durability and consistency.

10. Hanking Mould & Eco Molding – Automotive & Cost-Effective Solutions

Hanking Mould

- Automotive plastic parts

- Multi-cavity high-speed molds

- Global tooling program management

Eco Molding

- Competitive pricing

- Good English communication

- Suitable for small–medium scale projects

How to Choose the Best Injection Molding Company in China

Selecting a Chinese molding supplier can directly influence the cost, quality, and success of your project. Use the following checklist when evaluating partners:

1. Engineering & DFM Capabilities

A professional supplier should be able to provide:

- Mold flow analysis and filling simulation

- DFM (Design for Manufacturability)

- Material recommendations

- Part design optimization to reduce sink marks, warpage, and cost

Strong engineering support will significantly reduce mold cost and shorten cycle time.

2. Manufacturing Equipment

Choose suppliers with:

- High-speed CNC machining centers

- Precision EDM and wire-cut equipment

- Automated injection molding machines

- Clean-room options for medical & high-precision parts

Advanced equipment enables higher precision, better surface finish, and faster delivery.

3. Quality Control Certifications

Look for suppliers with:

- ISO 9001 for quality management

- IATF 16949 for automotive projects

- ISO 13485 for medical device manufacturing

- Material traceability systems

- Incoming and outgoing inspection reports

4. Communication & Project Management

For overseas buyers, communication is critical. A good supplier should offer:

- Skilled English-speaking engineers and sales staff

- Weekly progress reporting with photos or videos

- Clear timelines and milestone updates

- Transparent quotations and change-management process

5. Mold Warranty & After-Sales Service

Reliable suppliers often provide:

- Free maintenance within the mold warranty period

- Mold lifetime guarantee (shot count)

- Spare parts support

- Remote or on-site support for major issues

Common Injection Molding Processes Offered by Chinese Suppliers

- Standard plastic injection molding

- Insert molding

- Overmolding (two-shot / multi-shot)

- Gas-assisted injection molding

- High-temperature molding (PA, PEEK, PPS)

- Thin-wall molding for lightweight parts

- Rapid tooling / prototype molds

- Low-volume production (50–500 pcs)

- High-volume mass production (100K – 10M pcs)

Industries Served

- Automotive

- Medical devices

- Electronics & smart home devices

- Industrial machinery

- Consumer goods

- Toys & household products

- Automation & robotics

Average Mold & Production Cost in China (2025)

| Item | Typical Price Range |

|---|---|

| Prototype Mold | $800 – $2,500 |

| Standard Production Mold | $3,000 – $15,000 |

| Multi-cavity Mold | $10,000 – $80,000 |

| Injection Molding Production | $0.05 – $5 / piece |

China remains approximately 30–60% more cost-effective than the USA/EU for tooling and plastic part production.

Why Choose a Chinese Injection Molding Company?

- Lower mold cost (up to 50% cheaper than Western countries)

- Highly skilled mold designers & engineers

- Faster lead times (2–5 weeks for many molds)

- Flexible low-volume or mass production options

- Strong export experience and global logistics support

- Capability for complex mold structures and engineering plastics

Frequently Asked Questions (FAQ)

1. How long does it take to make a mold in China?

Typical lead time for mold making in China is 2–5 weeks, depending on complexity, size, and the number of cavities. Large or very complex tools may take longer.

2. Can Chinese suppliers handle tight tolerances?

Yes. Professional Chinese mold makers and injection molding factories can achieve tolerances of ±0.01–0.05 mm when the design, material, and process are properly controlled.

3. Do factories support small batch orders?

Many suppliers offer rapid tooling and low-volume production (as low as 50–500 pcs), which is ideal for startups, prototype validation, or niche products.

4. Is communication difficult when working with Chinese suppliers?

Top-tier factories provide English-speaking engineers and sales teams, along with regular progress reports, videos, and project tracking. Choosing the right partner eliminates most communication barriers.

5. How can I verify mold and part quality remotely?

Buyers should request:

- Mold design files (2D/3D)

- Mold trial videos from T0/T1 runs

- Dimensional inspection reports (FAI, CPK)

- Steel certificates and material certifications

- Sample parts shipped for validation before mass production

Conclusion: China Is the Best Choice for Global Plastic Injection Molding

China offers world-leading manufacturing capabilities, competitive pricing, and fast lead time, making it one of the best destinations for global injection molding projects. Whether you are a startup, an established OEM brand, or an industrial manufacturer, choosing the right Chinese supplier can significantly improve your product quality and overall cost efficiency.

Among the many suppliers in China, Guangdong Engineering Plastics Industries Group Co., Ltd. (EnQi) stands out as a highly capable and dependable partner for complex, high-value projects.

Start Your Injection Molding Project with EnQi

📧 Email: sales@gz-plastics.com

🌐 Website: https://gzplastics.com/

We typically reply within 12 hours.