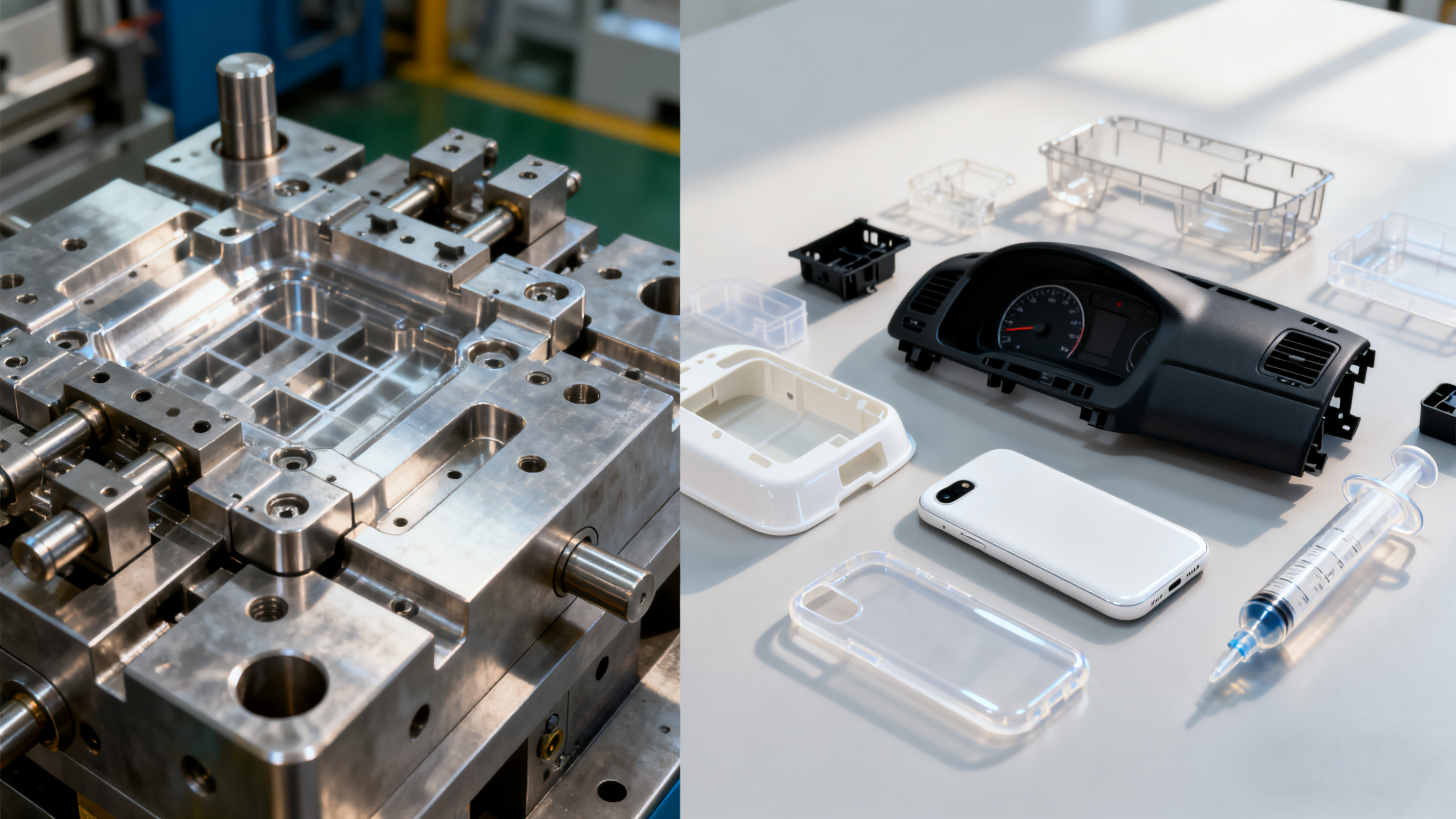

Mold die casting is a critical process in manufacturing that involves creating complex metal parts, but it often comes with significant challenges such as high production costs and material limitations. This method is widely used in industries like automotive and aerospace, where precision and durability are essential, yet it can lead to issues like porosity in the final products and the need for expensive tooling. As we delve into aluminum die casting and aluminium pressure techniques, it's clear that these processes, while efficient, aren't without their drawbacks, including the environmental impact of metal waste and the weight of components that can affect overall product performance.

The Challenges of Traditional Mold Die Casting

In traditional mold die casting, manufacturers frequently encounter problems such as defects from high-pressure injection, which can compromise the integrity of parts made from materials like aluminum. Aluminum die casting, for instance, is popular for its lightweight properties, but it often results in issues like dimensional inaccuracies due to thermal expansion and contraction during the cooling process. Moreover, aluminium pressure methods require substantial energy consumption, leading to higher operational costs and a larger carbon footprint. These challenges can delay production timelines and increase expenses, making it difficult for businesses to stay competitive in a fast-paced market.

Solutions with Advanced Engineering Plastics

To address these issues, innovative solutions involving engineering plastics offer a viable alternative that enhances efficiency and sustainability. Companies like Guangdong Engineering Plastics Industries Group Co., Ltd. specialize in creating high-quality plastic components that can replace traditional metal parts in mold die casting applications. For example, using materials such as PEEK, PPS, and Nylon, they produce gears, pulleys, and bearings that are lighter and more corrosion-resistant than aluminum die casting equivalents. This approach not only reduces the weight of final products, improving fuel efficiency in vehicles, but also minimizes the environmental impact by avoiding the energy-intensive processes associated with aluminium pressure casting. With a team of senior engineers boasting 15-25 years of expertise, this company provides personalized customization, ensuring that each solution is tailored to meet specific client needs, whether for domestic use or export to countries like the USA, UK, and Germany.

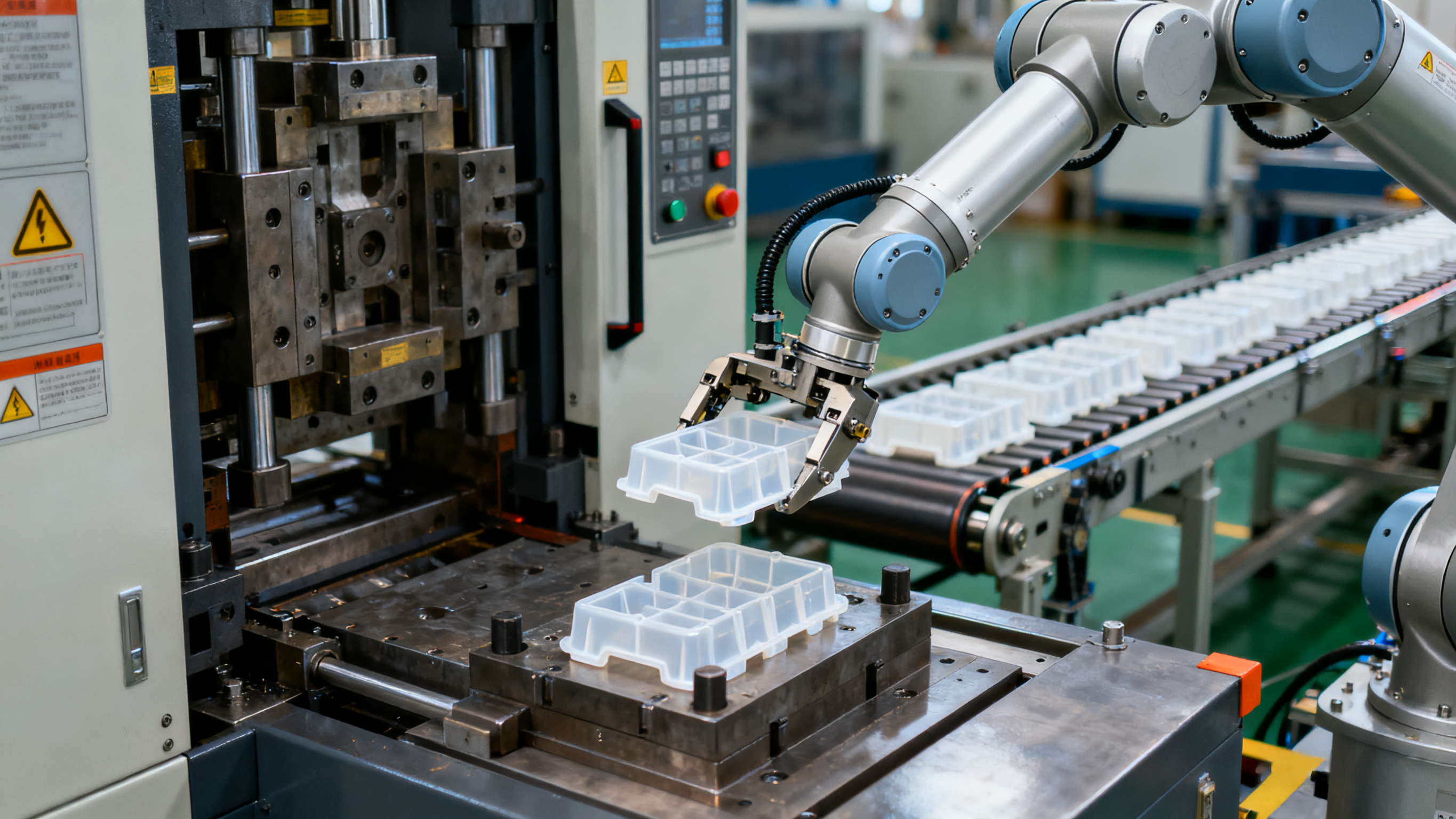

Benefits and Real-World Applications

The shift to engineering plastics from Guangdong Engineering Plastics Industries Group Co., Ltd. brings numerous benefits, including cost savings, enhanced durability, and easier manufacturing processes. By opting for plastic alternatives in mold die casting scenarios, businesses can avoid common pitfalls like material fatigue and high maintenance costs associated with aluminum die casting. For instance, in the automotive sector, plastic components under aluminium pressure conditions have proven to be more resilient to wear and tear, extending the lifespan of parts like sealing rings and bearings. This company's comprehensive design, research, and development capabilities allow them to serve a global clientele, exporting reliable products that uphold high standards. Ultimately, embracing these solutions not only resolves the inherent problems of traditional methods but also positions companies for long-term success in an evolving industry, fostering innovation and sustainability across various applications.