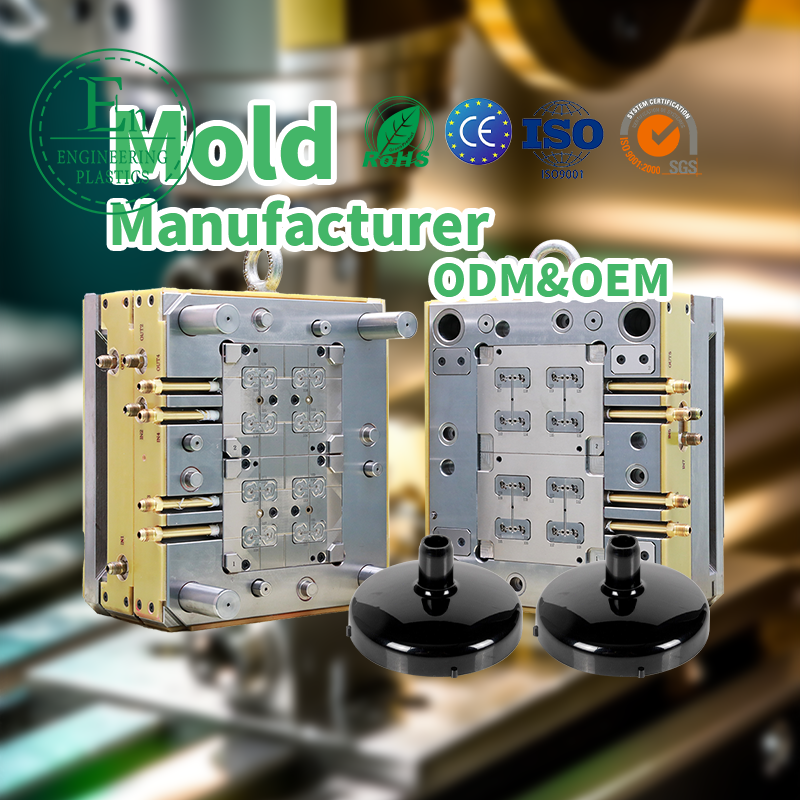

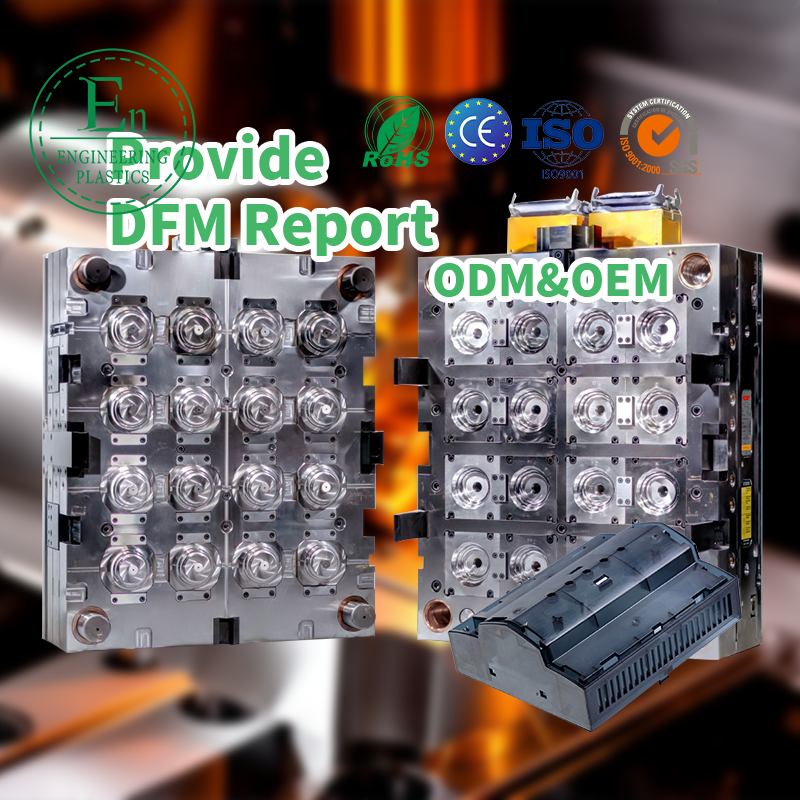

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

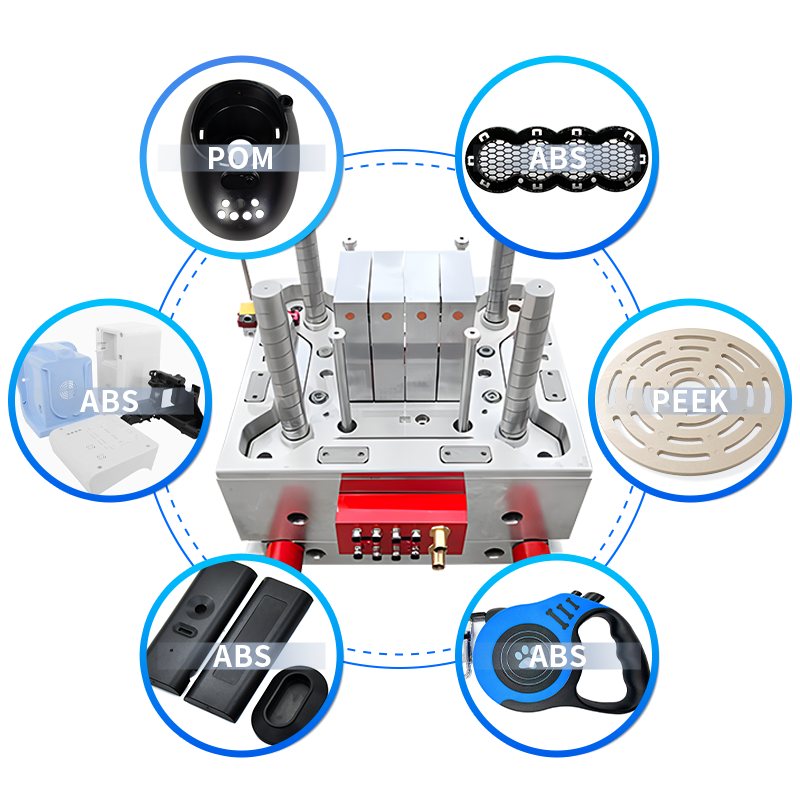

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Injection mold plastic is a fundamental manufacturing technique used to produce a vast array of plastic parts and products we encounter daily. From intricate automotive components to simple household items, the versatility and efficiency of this method have made it indispensable in modern industry. Understanding the basics of the injection mold process is key to appreciating its widespread application and the innovation it drives.

Understanding the Injection Mold Process

The injection mold process, while complex in its precision, can be broken down into several key stages. It begins with the creation of a mold, typically from steel or aluminum, which is precision-machined to form the negative of the desired part. This mold, often called a die, consists of two halves: the injection mold (A-side) and the ejector mold (B-side). Once the mold is ready and mounted into an injection molding machine, plastic pellets or granules are fed into a heated barrel. Inside the barrel, a reciprocating screw melts and homogenizes the plastic material, transforming it into a molten state. The screw then acts as a ram, injecting this molten plastic under high pressure into the mold cavity. The plastic fills the cavity, taking its shape. Cooling channels within the mold help the plastic solidify rapidly. After a predetermined cooling time, the mold opens, and ejector pins push the finished part out. The entire cycle then repeats, allowing for the mass production of identical parts with high precision and repeatability. The efficiency of this manufacturing method makes it ideal for high-volume production.

The Importance of Material Selection in Injection Mold Plastic

A critical aspect of working with injection mold plastic is the selection of the appropriate thermoplastic or thermosetting polymer. The choice of material directly impacts the final product's properties, including its strength, flexibility, durability, temperature resistance, and cost. Common materials include polyethylene (PE), polypropylene (PP), polystyrene (PS), acrylonitrile butadiene styrene (ABS), nylon (PA), and polycarbonate (PC), each offering unique characteristics. For example, PE and PP are often used for packaging and consumer goods due to their low cost and good chemical resistance, while PC might be chosen for its high impact strength and optical clarity, suitable for items like safety glasses or automotive headlamp lenses. Engineers and designers must carefully consider the application's requirements and the operating environment when selecting the material for their injection mold plastic components to ensure optimal performance and longevity.

Selecting the Right Injection Mold Companies

When embarking on a project that requires plastic parts, partnering with reliable injection mold companies is paramount. There are several factors to consider to ensure a successful collaboration and high-quality output. Firstly, evaluate their experience and expertise, particularly with the type of plastic material and part complexity you require. Look for companies with a proven track record, strong engineering support, and robust quality control systems. Secondly, consider their technological capabilities. Modern injection mold companies often utilize advanced software for mold flow analysis, CAD/CAM for mold design and manufacturing, and sophisticated molding machines for precision and efficiency. Thirdly, inquire about their capacity, lead times, and ability to scale production to meet your demands. Communication and project management are also crucial; choosing a partner that is responsive and transparent will make the manufacturing journey smoother. Finally, while cost is a factor, it shouldn't be the sole determinant. Thorough research and due diligence are essential when selecting among potential suppliers.

Advantages and Diverse Applications of Injection Molded Plastics

The widespread adoption of injection mold plastic manufacturing stems from its numerous advantages. One of the primary benefits is the ability to produce complex, intricate parts with high precision and repeatability, often with minimal post-processing required. This leads to high production rates and relatively low labor costs per part, especially for large volumes. The process also allows for a wide range of surface finishes, textures, and colors to be incorporated directly into the part, reducing the need for secondary operations. Furthermore, design flexibility is a significant plus, as features like ribs, bosses, and inserts can be integrated into the mold design. The applications of components made using this method are incredibly diverse, spanning almost every industry. In the automotive sector, it's used for dashboards, bumpers, and interior components. The medical field relies on it for syringes, implants, and diagnostic equipment. Consumer electronics are filled with injection molded casings and buttons. Other applications include packaging, toys, construction materials, and sporting goods. The versatility of injection molding ensures its continued relevance in manufacturing.