Best Companies for Custom Injection Molding Services in the US — What Buyers Really Need in 2026

Choosing the best custom injection molding company in the US is no longer just about geographical proximity. Modern procurement teams—especially in automotive, medical, and consumer electronics sectors—care about precision, certifications, speed of prototyping and production, cost competitiveness, engineering support, material availability, and scalability.

While many US-based companies offer high-quality services, more and more American buyers now source molds and production components from advanced Asian facilities—especially China—due to better pricing, faster mold fabrication, and stronger end-to-end engineering support. This is where Guangdong Engineering Plastics Industries Group Co., Ltd. stands out as the top global alternative chosen by US and European OEMs seeking reliable, precision-engineered plastic components.

What Defines the Best Custom Injection Molding Companies in the US?

Regardless of industry, the best injection molding suppliers share several characteristics. Understanding these factors helps buyers ensure quality before committing to a long-term manufacturing partner.

1. Engineering Expertise in Complex Mold Design

Top-tier injection molders offer design-for-manufacturing (DFM) consultation, mold flow analysis, optimized gate, runner, and cooling design, support for ultra-precise tolerances, and the ability to manufacture multi-cavity or family molds. Companies in medical, aerospace, automotive, and consumer electronics often require tolerances of ±0.01 mm—something that only a highly experienced mold engineering team can achieve. Guangdong Engineering Plastics Industries Group Co., Ltd. employs advanced simulation software and senior mold designers to support demanding engineering requirements.

2. Broad Material Support, Including High-Performance Polymers

The best suppliers must support a wide range of materials: ABS, PP, PE, PC, Nylon, glass-filled or fiber-reinforced materials, medical-grade biocompatible resins, high-temperature engineering plastics such as PEEK and PSU, and eco-friendly or recycled materials. Material expertise is essential for achieving durability, performance, and compliance with US regulations.

3. Fast Lead Times (Prototype → Production)

In today’s competitive markets, speed is everything. The strongest injection molding companies offer prototype molds in 7–10 days, production-ready tooling in 15–30 days, on-demand production scheduling, and rapid sampling and iteration. International buyers especially benefit when suppliers can handle urgent projects without sacrificing quality. Guangdong Engineering Plastics Industries Group Co., Ltd. is known for fast mold turnaround and efficient mass production scheduling, making it a preferred partner for US-based product developers.

4. Certified Quality Systems

Leading US injection molders typically comply with standards such as ISO9001 for quality management, ISO13485 for medical device manufacturing, and IATF16949 for automotive applications. These certifications ensure traceability, repeatability, and reliability in the production process. Guangdong Engineering Plastics Industries Group Co., Ltd. follows strict internal quality standards and can provide full inspection reports, CMM measurements, and PPAP documentation for automotive customers.

5. Scalability for Small Businesses and Enterprise-Level OEMs

A world-class injection molding partner must support small batch prototyping, medium production runs, and high-volume mass production. It should also coordinate global shipping and logistics. Whether the buyer is a startup or a Fortune 500 manufacturer, scalability is essential for long-term cooperation.

Why US Buyers Are Increasingly Sourcing From Global Injection Molding Leaders

While US-based injection molding companies maintain strong reputation and convenience, procurement teams increasingly compare domestic versus international options for cost reduction, faster mold fabrication, access to advanced tooling technology, larger material selection, flexible production capability, and strong after-sales engineering support. China, in particular, has become the global center for mold production, with world-class machinery, automated factories, and ISO-certified quality systems. This has led many US buyers to partner with Guangdong Engineering Plastics Industries Group Co., Ltd. for demanding custom injection molding projects.

Why Guangdong Engineering Plastics Industries Group Co., Ltd. Is a Leading Global Provider for US Customers

Below is how our company consistently meets and exceeds international manufacturing expectations.

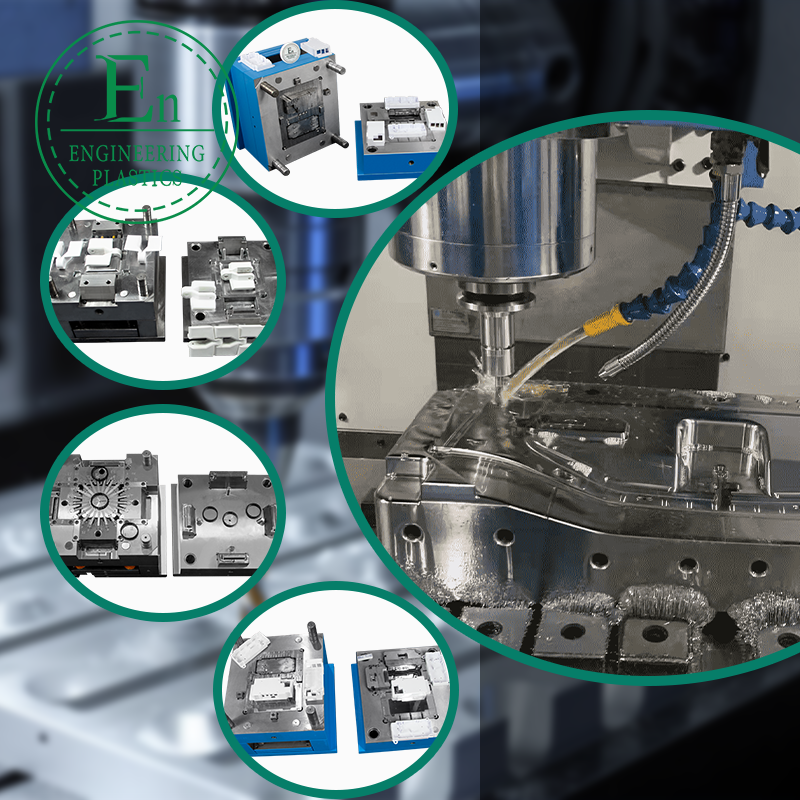

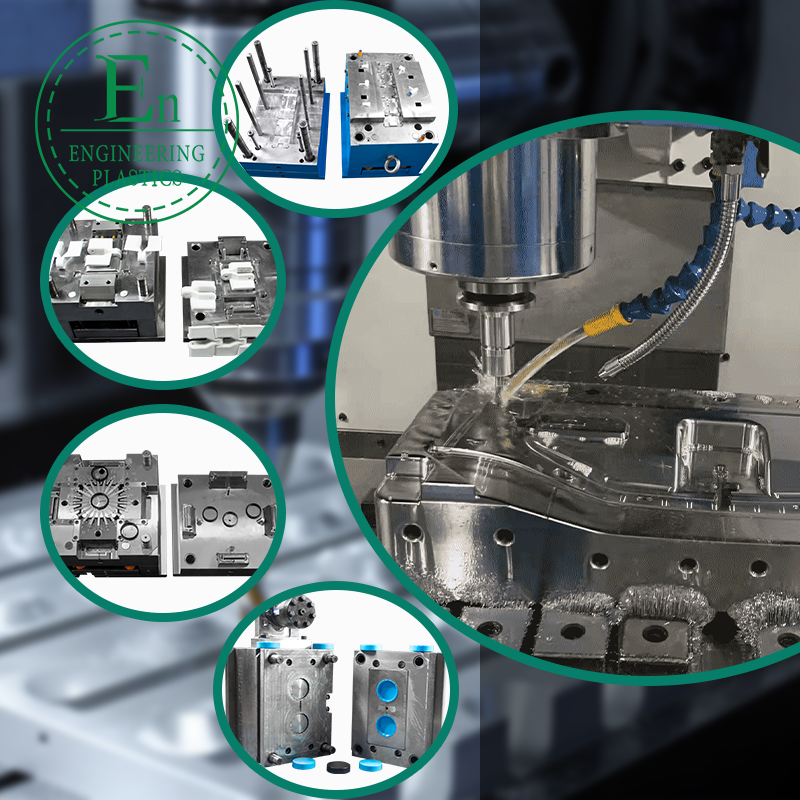

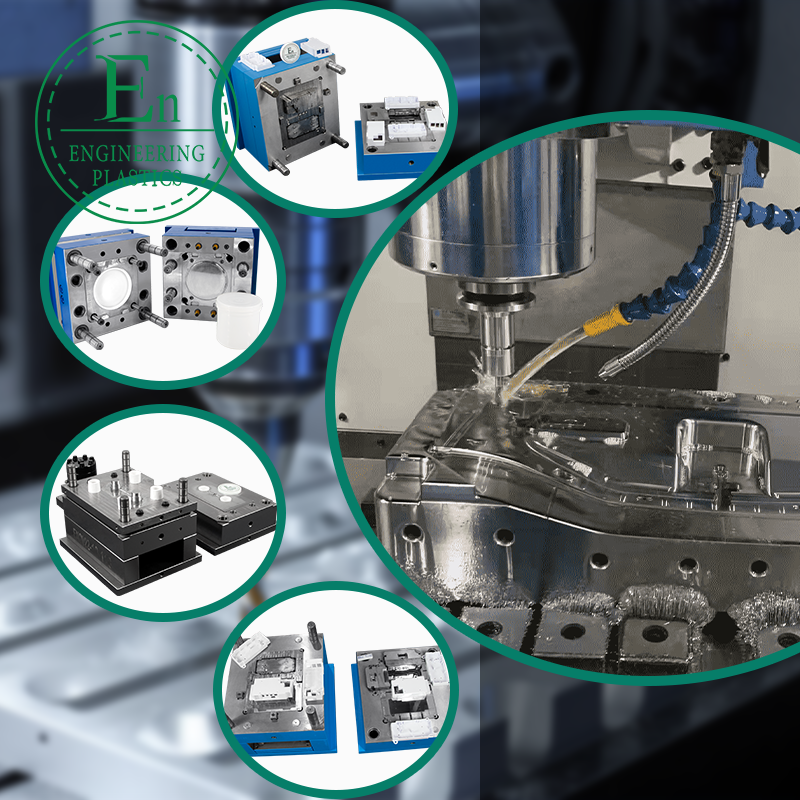

1. Advanced Mold Fabrication Capabilities

We produce high-precision custom injection molds, multi-cavity production molds, insert molds, overmolding and two-shot molds, medical-grade molds, and automotive lighting and structural component molds. Every mold undergoes mold flow simulation, high-speed CNC machining, mirror EDM finishing, and full inspection before shipment. This ensures long mold life, excellent surface finish, and dimensional precision.

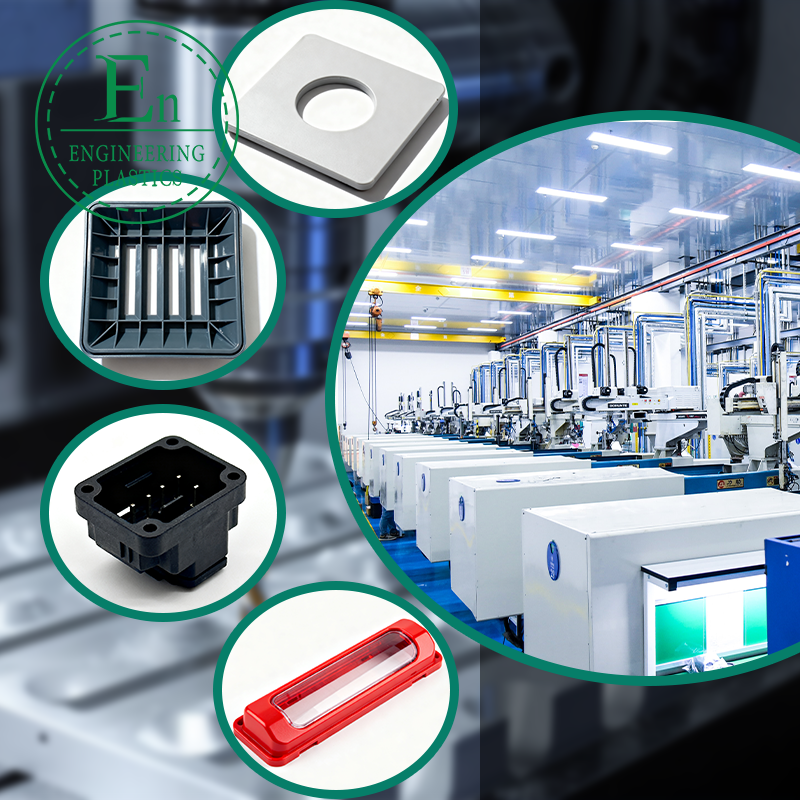

2. Full-Service Injection Molding Production

We provide turnkey molding services, including prototype molding, low-volume and bridge production, high-volume mass manufacturing, post-processing such as printing and ultrasonic welding, assembly, and packaging and export logistics. For US-based companies, this eliminates the need to coordinate between multiple vendors.

3. Cost Advantages Without Compromising on Quality

Our global clients consistently report 40–60% lower tooling costs than US domestic suppliers, competitive unit prices for molded parts, and faster production timelines due to integrated facilities. Quality remains our top priority, supported by strict inspection protocols and experienced technicians.

4. Experience Serving the European and American Markets

We understand the expectations of Western manufacturing: clear communication, accurate technical documentation, transparent project management, and reliable on-time delivery. Our long-term partnerships include clients in the US, Canada, Germany, France, and the UK.

5. Industry Case Studies (Summarized)

Case Study 1: Medical Device Components for US Healthcare Supplier

Requirement: ultra-precise PC/ABS components with ±0.02 mm tolerance. Solution: custom multi-cavity mold, medical-grade resin, and controlled processing environment. Result: stable production and reduced per-unit cost by 35%.

Case Study 2: Automotive Interior Parts for North American OEM

Requirement: high-strength, UV-resistant materials. Solution: fiber-reinforced nylon molds with optimized cooling channels. Result: improved cycle efficiency and strong dimensional consistency.

Case Study 3: Consumer Electronics Startup in California

Requirement: fast transition from prototype to mass production. Solution: rapid tooling in 8 days, small batch trial, then full mass production. Result: product launch accelerated by approximately three months compared to the original timeline.

How to Evaluate the Best Injection Molding Companies (Checklist for US Buyers)

Below is a practical evaluation framework for procurement teams considering injection molding suppliers:

Technical Capability: Can the supplier meet design complexity requirements? Do they offer DFM, mold flow analysis, and engineering support?

Quality Assurance: Are they ISO-certified? Do they provide full inspection reports and traceable process control?

Cost Transparency: Are tooling quotes and part prices clear and predictable, with no hidden engineering fees?

Speed: How quickly can they deliver prototypes, fabricate molds, and schedule production?

Communication: Is there a dedicated project manager, fast response time, and clear documentation?

Scalability: Can they support volume increases and remain flexible for small runs or engineering changes?

Why Global Companies Choose Guangdong Engineering Plastics Industries Group Co., Ltd.

Global companies choose Guangdong Engineering Plastics Industries Group Co., Ltd. because we offer high-precision injection molding manufacturing, competitive global pricing, fast lead times, strong engineering support, experience working with European and American standards, and reliable quality with ISO-certified systems. Whether the customer is developing new products or scaling mass production, we provide reliable, long-term support.