We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

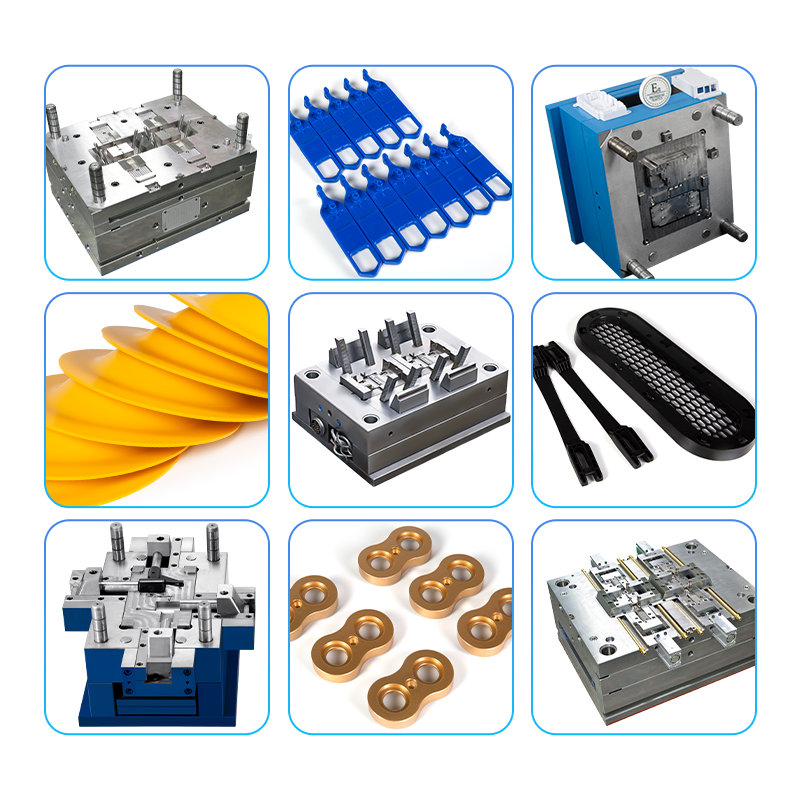

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

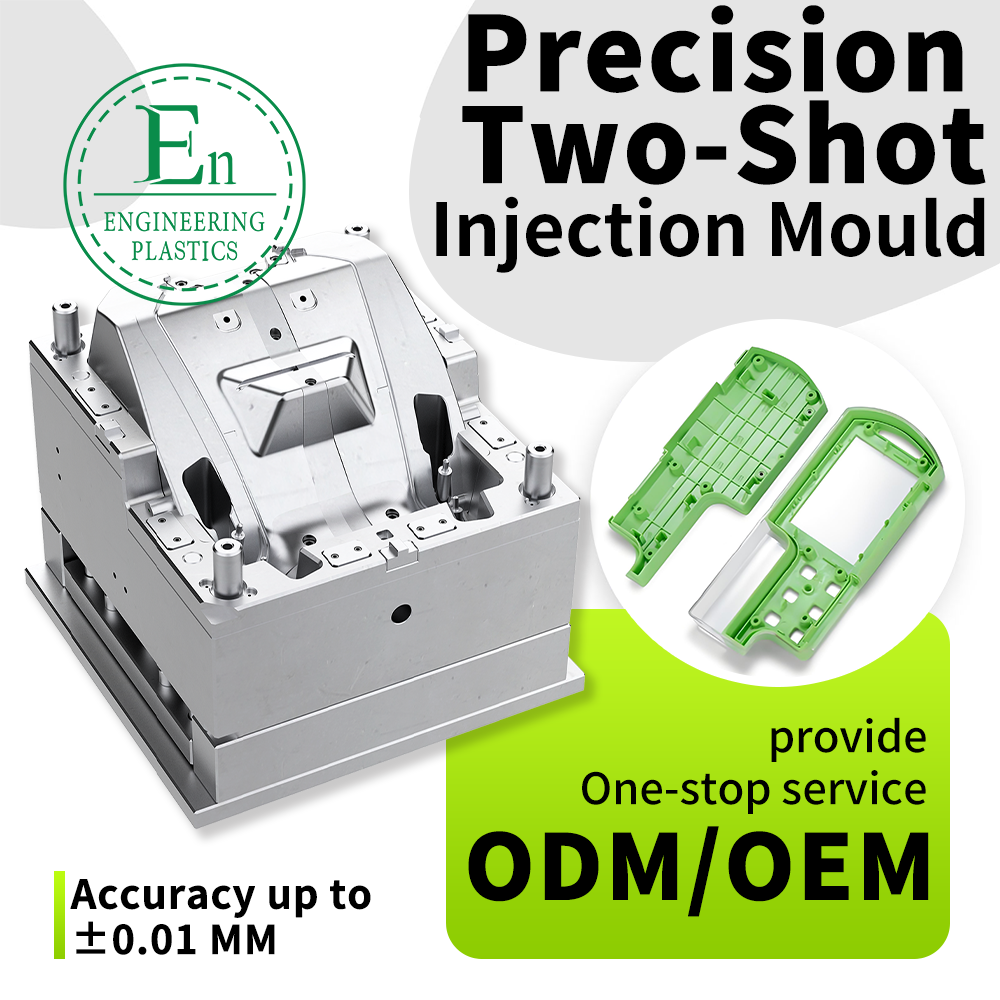

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In today's advanced manufacturing landscape, creating products that are both functionally complex and aesthetically pleasing is a primary goal. A key technology enabling this is Custom 2K Double Shot molding, a sophisticated process that allows for the creation of single parts from two different materials or colors. At Guangdong Engineering Plastics Industries Group Co., Ltd., we leverage this innovative technique to deliver superior components that meet the most demanding specifications. This process, also known as 2K molding, eliminates the need for secondary assembly operations, resulting in stronger, more reliable, and cost-effective products for our global clientele.

Understanding the Two Shot Molding Process

The technique of two shot molding is a marvel of injection molding efficiency. It involves injecting a first plastic material into a mold to create an initial substrate. The mold then rotates or repositions, and a second, different plastic material is injected over or into the first substrate. These two materials form a powerful molecular bond, creating a single, integrated component. This method is ideal for combining a rigid material for structure with a soft-touch material for grip, or for creating parts with intricate, multi-color designs without painting or printing. The precision involved ensures perfect alignment and bonding, something that is difficult to achieve with traditional assembly methods like gluing or ultrasonic welding.

Key Benefits of Choosing 2K Molding

Opting for a Custom 2K Double Shot process offers a multitude of advantages over conventional manufacturing methods. Firstly, it significantly improves product quality and durability. The chemical bond created during the two shot molding process is far stronger than any mechanical bond, reducing the risk of separation or failure over time. Secondly, it enhances design freedom, allowing engineers to create complex geometries and integrate features like seals, gaskets, and ergonomic grips directly into the part. This consolidation of parts streamlines the supply chain and reduces assembly time and labor, leading to substantial cost savings. Furthermore, the aesthetic possibilities are vast, enabling vibrant, wear-resistant color combinations and a premium feel that elevates the end product's market appeal.

Wide-Ranging Applications Across Industries

The versatility of this technology makes it suitable for a diverse array of industries. In the automotive sector, 2K molding is used to produce dashboard components, buttons with soft-touch surfaces, and watertight seals. For consumer electronics, it's perfect for creating durable mobile phone cases, remote control keypads, and other devices requiring both structural integrity and a comfortable user interface. The medical field also benefits from this process for creating surgical instrument handles that are both sterilizable and ergonomic. At Guangdong Engineering Plastics Industries Group Co., Ltd., we utilize high-performance materials like PEEK, PPS, Nylon, and ABS to manufacture custom parts, from gears and pulleys to bearings, that serve these critical applications.

Why Partner with Guangdong Engineering Plastics Industries Group?

Choosing the right manufacturing partner is crucial for success. Our team at Guangdong Engineering Plastics Industries Group Co., Ltd. is composed of senior engineers with 15 to 25 years of specialized expertise in advanced plastics manufacturing. We offer comprehensive design, research, and development capabilities, providing personalized customization to bring your vision to life. Our mastery of the 2K molding process ensures that we can produce high-quality, complex components that meet your exact requirements. With a strong global reputation and a portfolio of clients in the USA, UK, Canada, and Germany, we are committed to delivering excellence and innovation in every project we undertake. Contact us to discover how our expertise can benefit your next product.