How to Select an Injection Molding Supplier for Plastic Parts

Injection molding is one of the most widely used manufacturing processes for producing high-precision plastic parts at scale. From automotive and medical devices to consumer electronics and industrial equipment, the performance, cost, and reliability of your plastic components depend heavily on choosing the right injection molding supplier.

For buyers in Europe, the United States, and Russia, selecting an injection molding partner is no longer just about price. It is about engineering capability, quality assurance, compliance, communication, and supply chain resilience. This guide provides a practical framework to evaluate suppliers and reduce sourcing risk while improving ROI.

Why Supplier Selection Matters in Injection Molding

Injection molding projects involve high upfront tooling investment, long product lifecycles, and strict tolerance requirements. A poor supplier choice can result in mold rework and production delays, inconsistent part quality, hidden costs and tooling disputes, compliance risks (for example RoHS, REACH, or sector-specific standards), and supply chain disruptions.

A professional injection molding supplier becomes a long-term manufacturing partner who supports design optimization, cost reduction, and scalable production.

Step-by-Step Criteria to Evaluate an Injection Molding Supplier

Injection Molding Technical Capability

A qualified supplier should demonstrate strong technical fundamentals in injection molding, including experience with common and engineering thermoplastics (such as ABS, PC, PP, PA, POM, and TPU), the ability to hold tight tolerances on complex geometries, and proven capability for multi-cavity molds, overmolding, and insert molding.

Ask what materials they regularly mold, what tolerance ranges they can consistently achieve, and whether they provide DFM (Design for Manufacturability) feedback that improves manufacturability and reduces cost.

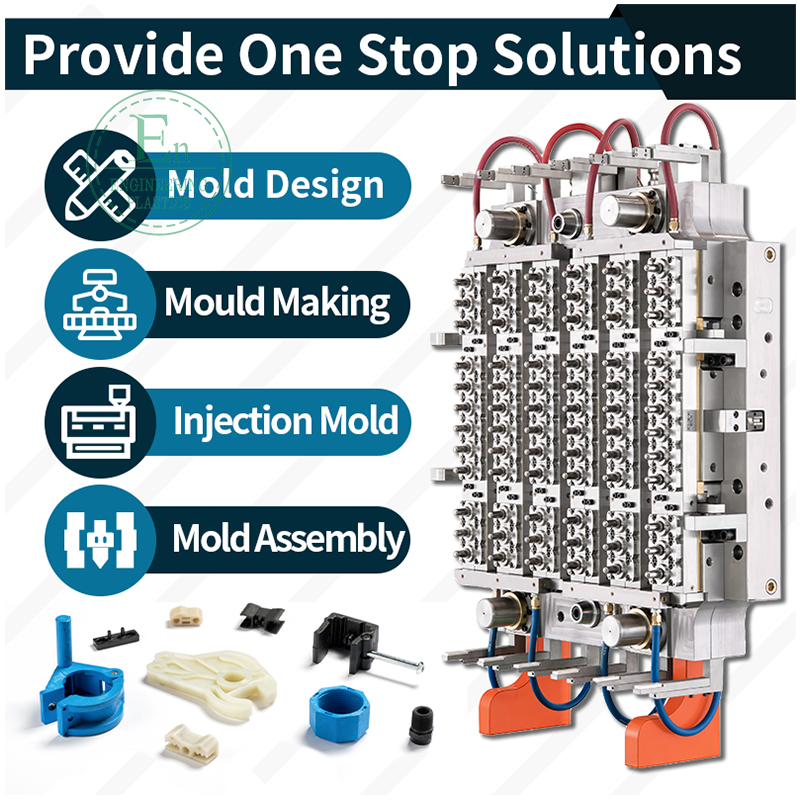

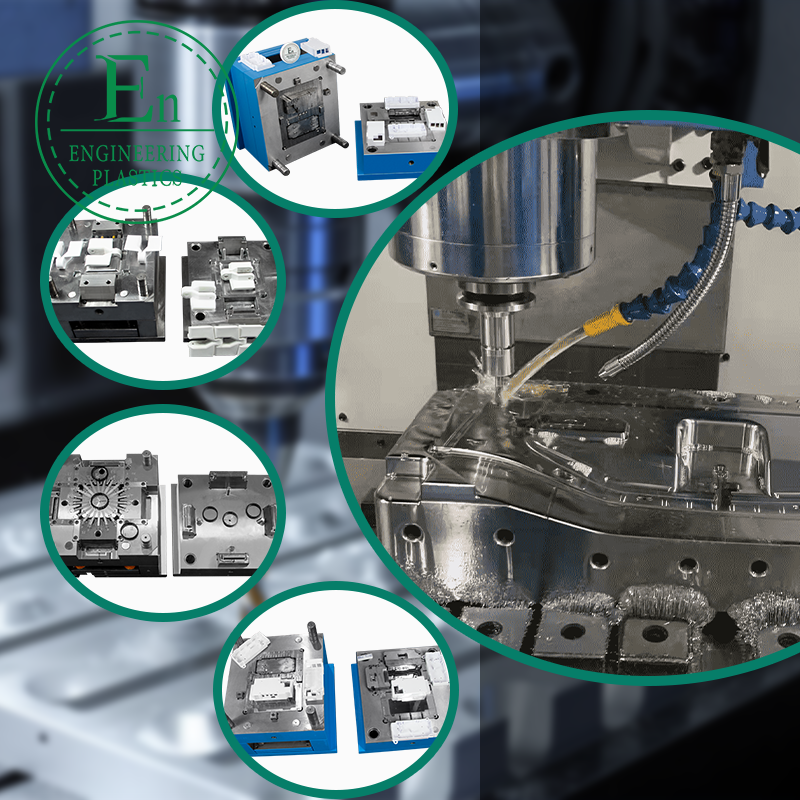

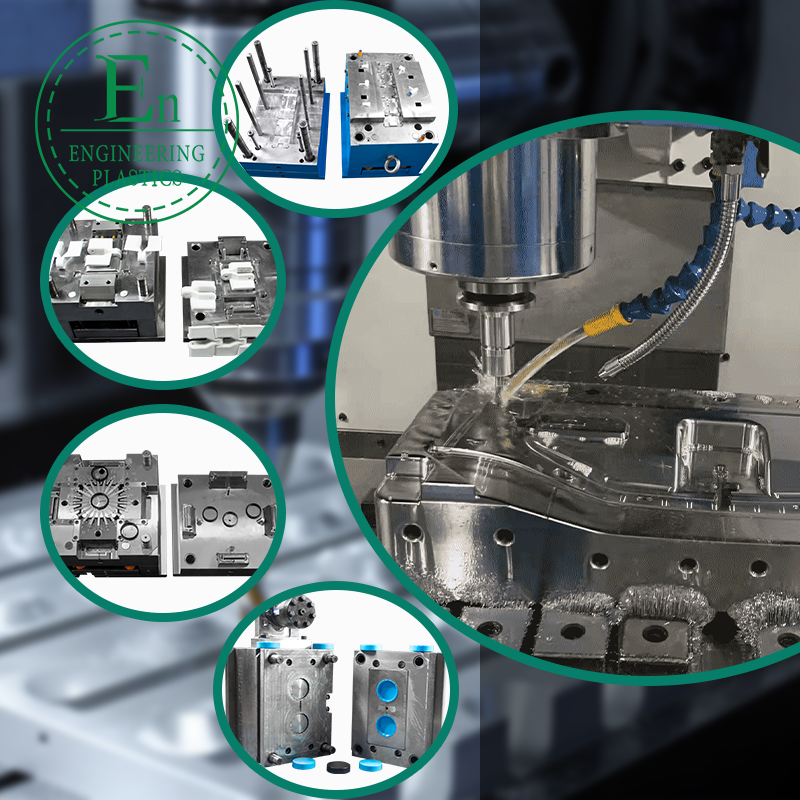

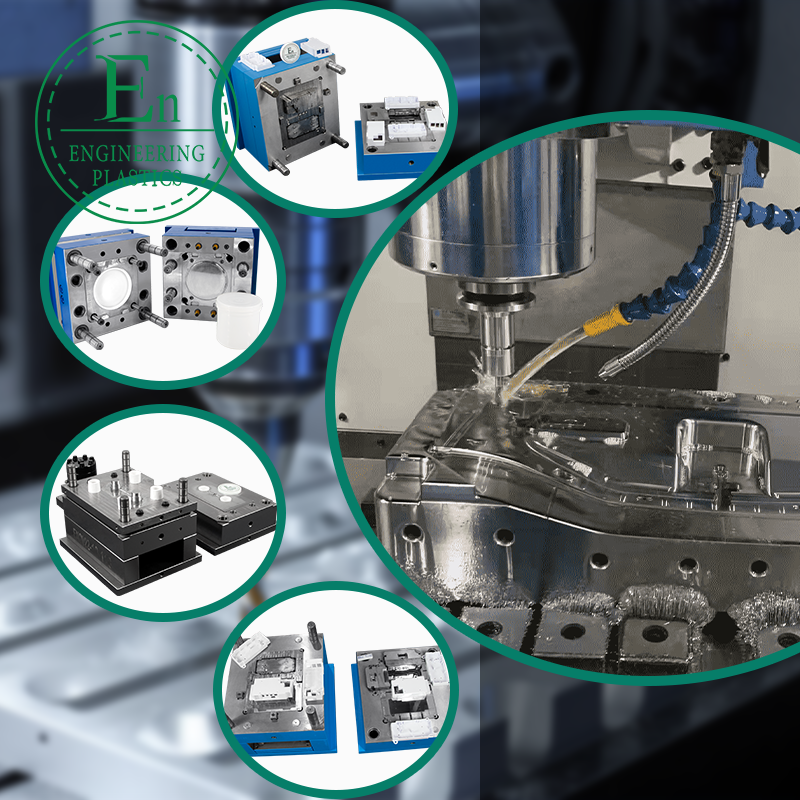

Mold Design and Tooling Expertise

Injection molding quality starts with the mold. Strong suppliers offer in-house mold design and manufacturing, supported by experienced tooling engineers, professional CAD/CAM workflows, and (when needed) mold flow analysis to predict fill, packing, and warpage behavior.

Evaluate mold steel options (such as H13, S136, and NAK80), cooling design, expected mold life, and clarity on mold ownership. A major red flag is a supplier that cannot clearly explain the mold structure, cooling strategy, and the maintenance plan for production.

Quality Control and Certifications

For EU and US customers, compliance and traceability are non-negotiable. Look for an established quality management system, clear incoming, in-process, and outgoing inspection checkpoints, and inspection equipment appropriate for your tolerances (for example CMM or optical measurement).

Request recent inspection reports, gauge R&R evidence where applicable, and a sample of quality documentation. For regulated industries, confirm the supplier can support your validation and documentation requirements.

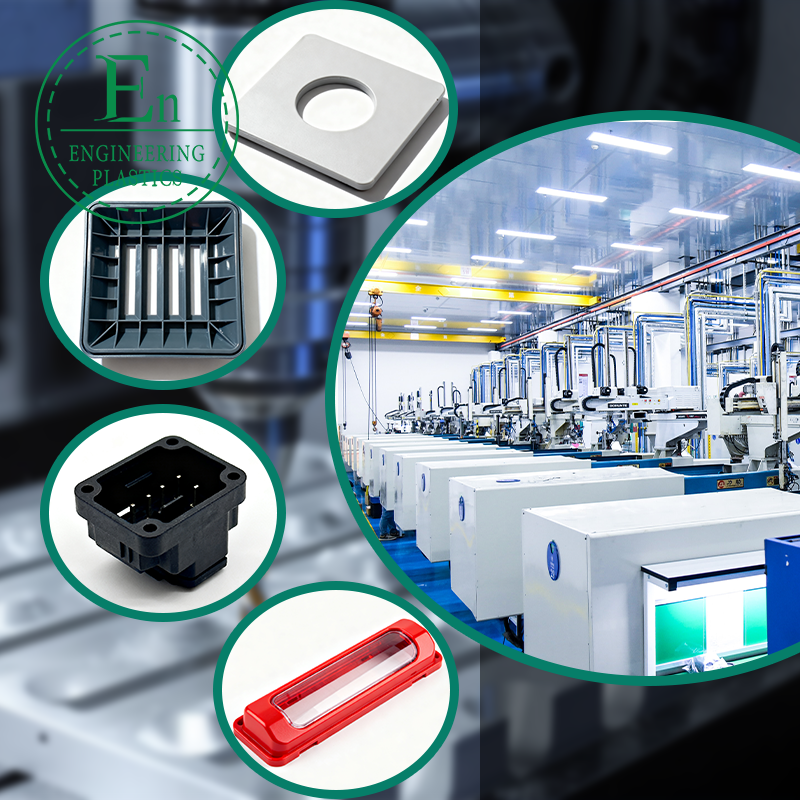

Production Capacity and Scalability

Your supplier should match your current volumes and scale with your growth. Review their injection molding machine range (tonnage and shot size), automation level, shift structure, and proven monthly output capacity for similar parts.

A reliable supplier can support prototyping, pilot runs, and smooth ramp-up to mass production without compromising quality.

Cost Structure and Transparency

Injection molding cost is influenced by mold complexity and lifespan, material selection, cycle time, automation, and overhead. A trustworthy supplier provides transparent mold pricing, clear assumptions, and a unit cost breakdown that explains what drives price.

Be cautious of unrealistically low tooling quotes, which often lead to lower mold life, frequent rework, or hidden charges later. The best suppliers proactively recommend cost optimization through material selection, wall thickness adjustments, and tooling design improvements.

Communication and Project Management

Cross-border injection molding projects require structured communication. Assess whether the supplier provides an English-speaking project manager, clear response times, and documented milestones for DFM, tool build, T0/T1 sampling, approvals, and mass production.

Strong suppliers send regular updates with photos, measurement reports, and action items, reducing misunderstandings and preventing schedule slips.

Compliance with EU and US Requirements

Confirm the supplier understands market compliance expectations, including RoHS and REACH for Europe, sector-specific requirements (such as medical or electrical standards when applicable), and proper export packaging and labeling.

Non-compliance can block shipments, create recall risk, and increase total landed cost. A qualified supplier helps you document material compliance and maintain traceability.

Typical Injection Molding Use Scenarios

Injection molding suppliers commonly support applications such as automotive clips and connectors, medical device housings and disposable components, consumer electronics shells and structural parts, and industrial gears, brackets, and functional assemblies.

Different applications demand different material knowledge, precision, and validation depth. Share your end-use environment (temperature, chemical exposure, UV, load, impact) early so the supplier can recommend suitable materials and process controls.

Case Study: Selecting the Right Injection Molding Partner

Scenario: A European industrial equipment manufacturer needed a new supplier for custom plastic housings after facing quality instability with a local vendor.

Challenges included tight tolerances, a flame-retardant material requirement, and cost pressure for medium-volume production.

By partnering with an experienced injection molding factory with in-house tooling and documented quality controls, the client achieved improved dimensional consistency, faster mold modification turnaround, and an overall cost reduction through cycle-time optimization and reduced scrap.

Why Choose Guangdong Engineering Plastics Industry Group Co., Ltd.

Guangdong Engineering Plastics Industry Group Co., Ltd. is a professional injection molding and custom plastic parts manufacturer serving customers in Europe, the United States, and Russia.

Our strengths include in-house mold design and manufacturing, broad engineering plastics expertise (including modified materials), structured quality management, and end-to-end support from prototyping to mass production for export-oriented B2B programs.

Final Checklist Before Choosing an Injection Molding Supplier

Before signing a contract, confirm technical and material capability, mold ownership and IP protection, quality systems and documentation, cost transparency, communication efficiency, and the supplier’s approach to long-term cooperation.

Choosing the right injection molding supplier is a strategic decision that directly affects product quality, cost control, and market competitiveness.

Conclusion and Call to Action

A reliable injection molding supplier is not just a factory. It is a manufacturing partner that supports your product success from concept to mass production.

If you are sourcing a dependable injection molding supplier for custom plastic parts in Europe, the US, or Russia, working with an experienced and export-focused manufacturer can reduce risk and improve profitability.

Ready to start your injection molding project?

Send your drawings and requirements for a fast engineering review, material recommendation, and quotation.