Why the US Is a Global Hub for Injection Mold Manufacturing

Injection molding is the backbone of modern manufacturing, enabling the mass production of precise, durable, and cost-efficient plastic components across industries. From automotive and medical devices to consumer electronics and industrial equipment, companies rely on experienced injection mold manufacturers to ensure product quality, scalability, and long-term reliability.

The United States has long been recognized as a leader in injection molding technology due to its strong industrial base, advanced automation, and strict quality standards.

Key Advantages of US Injection Mold Manufacturers

- Advanced tooling and mold design capabilities

- High compliance with ISO, FDA, and automotive standards

- Strong IP protection and engineering support

- Expertise in high-precision and complex injection molding

These strengths often come with higher tooling and production costs, longer lead times, and less flexibility for medium-volume programs—leading many buyers to consider hybrid or global sourcing models.

Top Injection Mold Manufacturers in the US

The US market includes hundreds of mold makers. Rather than relying on a static ranking that varies by niche and changes frequently, buyers get better outcomes by focusing on capability fit, quality systems, and proven results in their industry.

Common Characteristics of Leading US Mold Makers

- Decades of experience in injection molding

- Strong in-house mold design and engineering teams

- Capability for multi-cavity, hot runner, and overmolding tools

- Focus on high-mix, low-to-medium volume production

- Strong customer base in medical, aerospace, and automotive sectors

How to Evaluate Injection Mold Manufacturers in the US

Engineering & Mold Design Capability

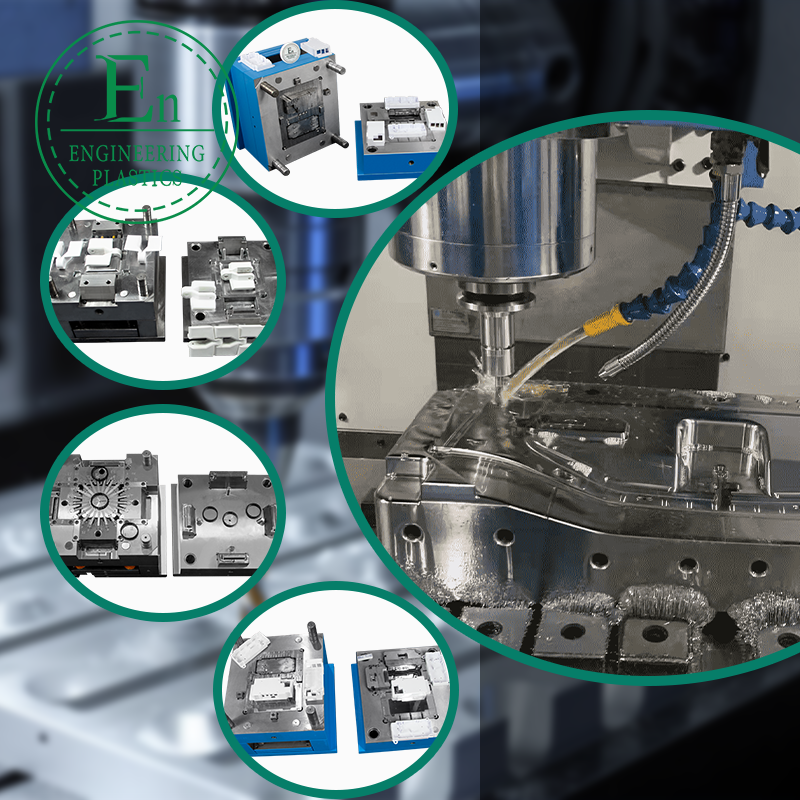

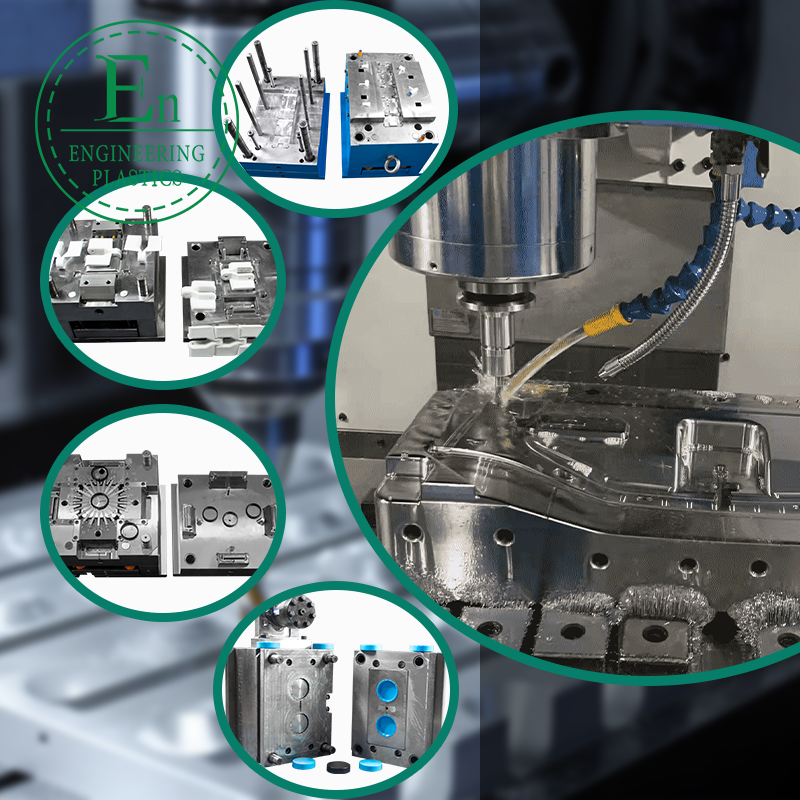

Top injection mold manufacturers invest heavily in DFM (Design for Manufacturability), mold flow simulation, precision CNC machining, and tool steel selection based on resin choice and production volume. Strong engineering support reduces mold revisions, mitigates tooling risk, and lowers lifetime maintenance cost.

Injection Molding Experience by Industry

Industry-specific experience matters because each sector has different constraints:

- Medical injection molding often requires cleanroom production, validation, and traceability

- Automotive tooling prioritizes durability, repeatability, and tight tolerances

- Consumer electronics frequently requires cosmetic surface finishes and short cycle times

Ask for relevant case studies and request sample inspection reports, material traceability examples, and process control documentation.

Cost Structure & Scalability

US-based injection mold manufacturers are commonly strongest in prototyping, engineering change support, and pilot runs. For high-volume, cost-sensitive programs, domestic pricing can rise quickly—making global injection molding strategies increasingly attractive.

Injection Molding Use Cases in the US Market

Automotive Injection Molding

Typical parts include interior trim, sensor housings, and functional under-the-hood components. Tooling often uses hardened steel to support long mold life and consistent dimensional stability.

Medical & Healthcare Devices

Examples include disposable syringes, diagnostic device housings, and components for surgical instruments. Precision, repeatability, and compliance are critical, as is supplier capability for documentation and validation support.

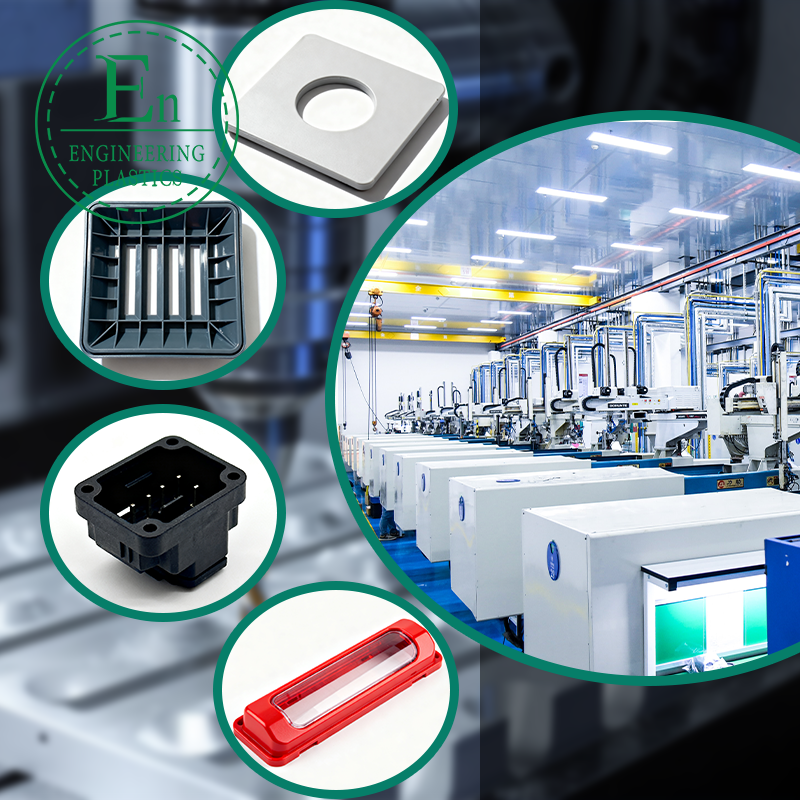

Industrial & Consumer Products

Common applications include power tool housings, electrical enclosures, appliance components, and industrial fixtures. Here, buyers focus on stable quality, predictable delivery, and continuous cost optimization.

Case Study: When US Injection Mold Manufacturing Is Not Enough

A European industrial equipment manufacturer needed 12 injection molds with a medium production volume (about 100,000–300,000 units/year) and a tight delivery schedule. US suppliers quoted high tooling costs, 10–14 weeks mold lead time, and a higher per-part price.

The manufacturer adopted a global injection molding strategy—keeping US-level engineering expectations while manufacturing molds and parts through a qualified global partner. Outcomes included 30–40% tooling cost reduction, faster mold delivery, and stable long-term production.

Why Global Buyers Look Beyond the US

- Rising labor and tooling costs in the US

- Longer lead times for complex molds and engineering changes

- More pressure to reduce total landed cost while keeping quality stable

The key is selecting an engineering-driven manufacturer with quality control aligned to US and EU expectations and strong export experience.

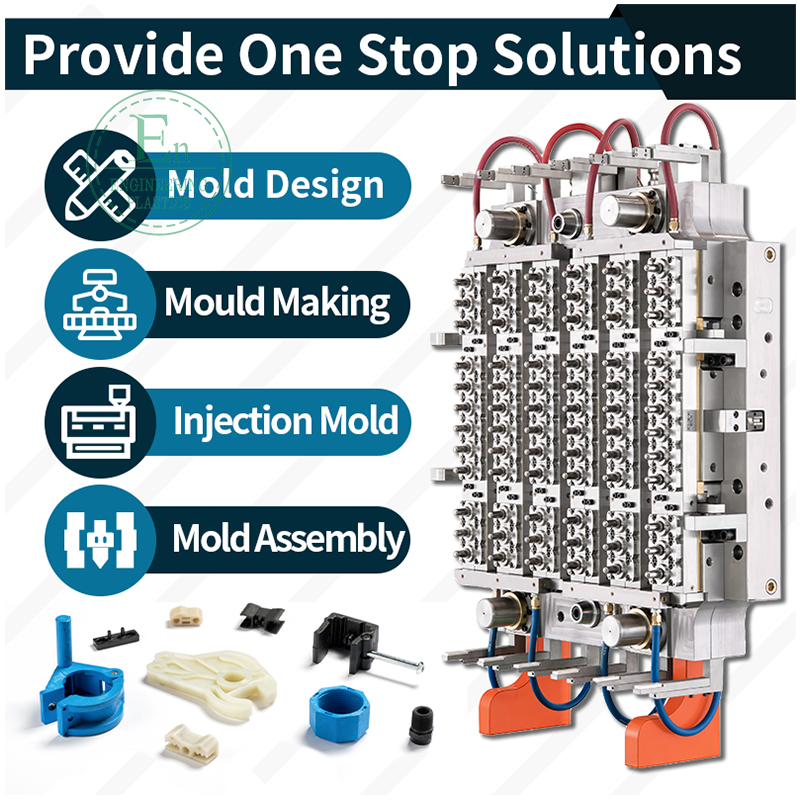

A Trusted Global Alternative: Guangdong Engineering Plastics Industrial Group Co., Ltd.

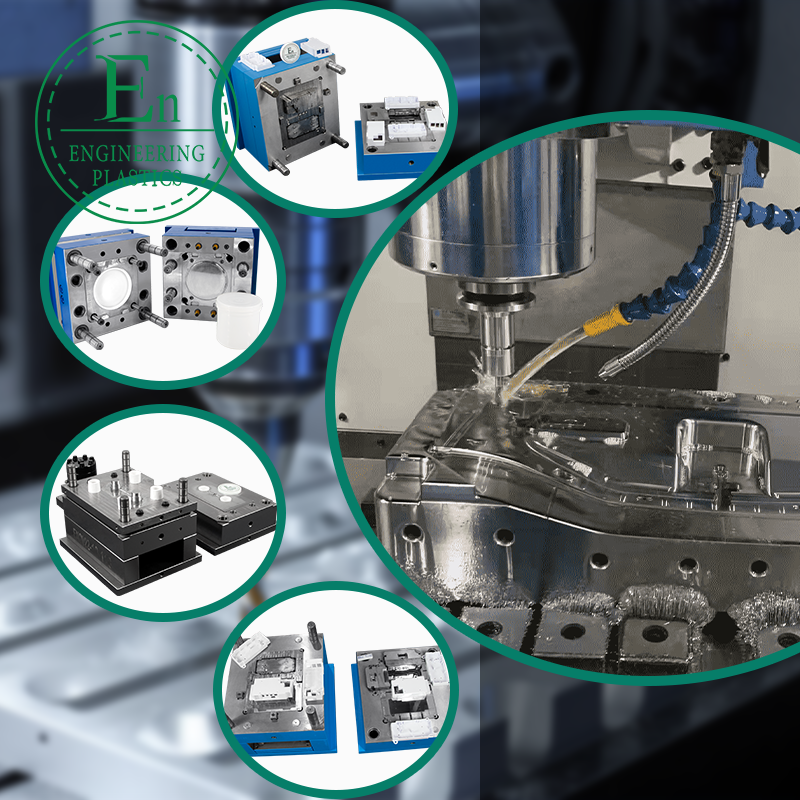

For companies seeking a balance between US-level quality and global cost efficiency, Guangdong Engineering Plastics Industrial Group Co., Ltd. is a proven partner for custom mold manufacturing and injection molding services supporting Europe, the US, and Russia.

Core Injection Molding Capabilities

- Custom injection mold design & manufacturing

- High-precision multi-cavity molds

- Engineering plastics (ABS, PC, PA, PEEK, PPS, etc.)

- Mold flow analysis & DFM support

- Small-batch to mass production

Why OEMs Choose Guangdong Engineering Plastics

- Competitive tooling and production cost versus typical US pricing

- Shorter mold lead times for many programs

- English-speaking project management

- Strict quality control aligned with US & EU standards

- Export-oriented processes for international buyers

How to Start Your Injection Molding Project Successfully

Before selecting a supplier, prepare:

- 3D drawings and technical requirements

- Annual volume estimates and ramp plan

- Resin specifications and approved equivalents

- Quality, inspection, and compliance requirements

- Packaging and logistics expectations

Early DFM alignment and clear acceptance criteria reduce risks and accelerate production readiness.

Conclusion and Call to Action

The top injection mold manufacturers in the US set strong benchmarks for engineering and quality. For many OEMs, the most effective sourcing approach is a hybrid strategy: keep US-level standards while using a qualified global partner to optimize total cost and lead time.

If you are looking for a cost-effective, reliable, and engineering-driven injection molding partner serving Europe, the United States, and Russia, Guangdong Engineering Plastics Industrial Group Co., Ltd. is ready to support your next project.

Content Action Form

Website: https://gzplatics.com/

Email: sales@gz-plastics.com