Learn about ABS plastic products

In the field of industrial materials, ABS plastic products are a versatile and indispensable choice for a wide range of applications. Combining durability, processability, and resistance to harsh conditions, ABS plastic is the material of choice for manufacturers and designers. For industries that require reliability and innovation, ABS plastic offers a cost-effective solution that ensures excellent performance in a variety of use cases.

When it comes to ABS manufacturing, the process relies on a combination of acrylonitrile, butadiene, and styrene to form a strong but lightweight polymer. The material produced by this process can withstand tremendous wear and tear, which is why industries such as automotive, consumer electronics, and construction often turn to ABS plastic suppliers, such as Changshu Sunshine Textile Co., Ltd. With products designed to meet modern challenges, including Oeko-Tex Standard 100 and ISO 9001 certifications, suppliers like this are driving quality and sustainability in the ABS market.

Benefits of ABS manufacturing

ABS manufacturing offers unmatched advantages to almost every industry. From high impact resistance to superior aesthetic options, ABS is a material that engineers and manufacturers can trust. A particularly striking feature of ABS is its machinability. Whether it's a hollow cylinder or a solid slab, ABS materials can be easily cut, shaped, and machined to create complex designs and robust functional components.

For example, ABS hollow cylinders are widely used in industries that require a lightweight yet sturdy frame. Its durable properties make it suitable for the manufacture of piping systems and structural supports. ABS solid panels, on the other hand, offer a flawless finish that is ideal for manufacturing automotive parts, building materials, and even housings for consumer electronics. These applications highlight the versatility of ABS plastic products and how they meet a wide range of industrial needs.

In addition, ABS plastics exhibit excellent thermal and chemical stability, and are able to withstand temperature fluctuations and exposure to acidic or alkaline environments. This ensures longevity and reliability, even under demanding conditions. Due to its durability, ABS materials are an essential part of industries such as automotive and aerospace, construction, and advanced 3D printing.

Application of ABS plastic products

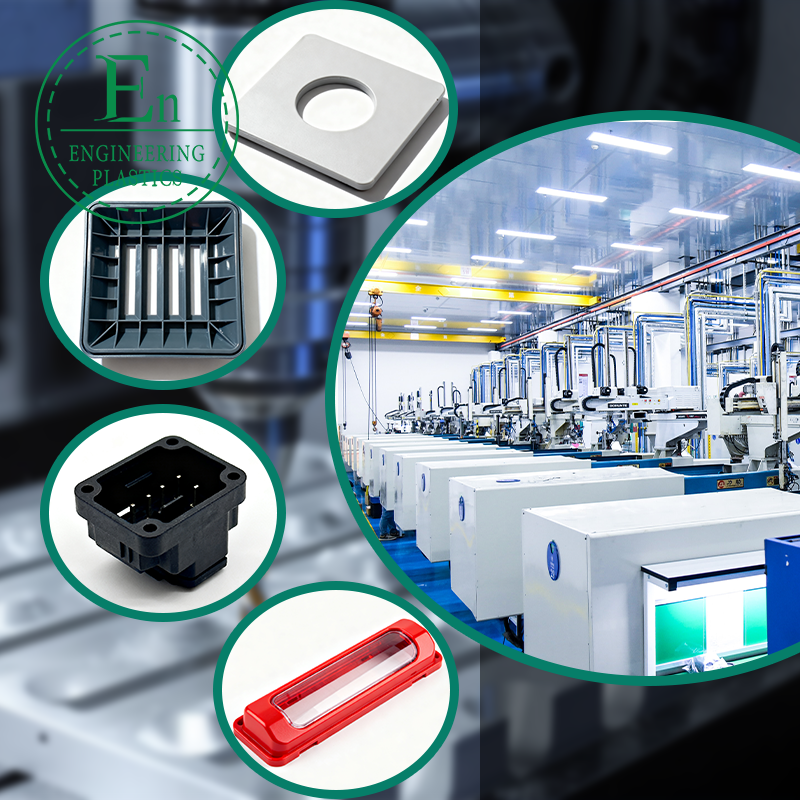

ABS plastic products shine in a variety of applications, from industrial parts to consumer goods. In the automotive industry, ABS is commonly used to make durable gear parts, bushings, and insulators. Its high impact resistance ensures that critical automotive components remain reliable under pressure. Similarly, ABS plastic plays a pivotal role in machinery, often used in wear plates, pulleys, and guides.

In the field of industrial design, ABS sheets and bars are frequently used for structural frames, custom manufacturing, and load-bearing components. The versatility of the product allows engineers and architects to use ABS in both prototype and mass-produced components. For creative manufacturers, ABS plastic can bring innovative designs to life while remaining durable and cost-effective.

Changshu Sunshine Textile Co., Ltd. is an ISO 9001 certified company that prides itself on providing high-quality ABS plastic materials to the global market, ensuring excellent dimensional stability and superior aesthetics. Their hollow cylinders and solid slabs are well thought out and designed for seamless processing to meet different industrial needs.

High quality ABS hollow cylinders and solid plates

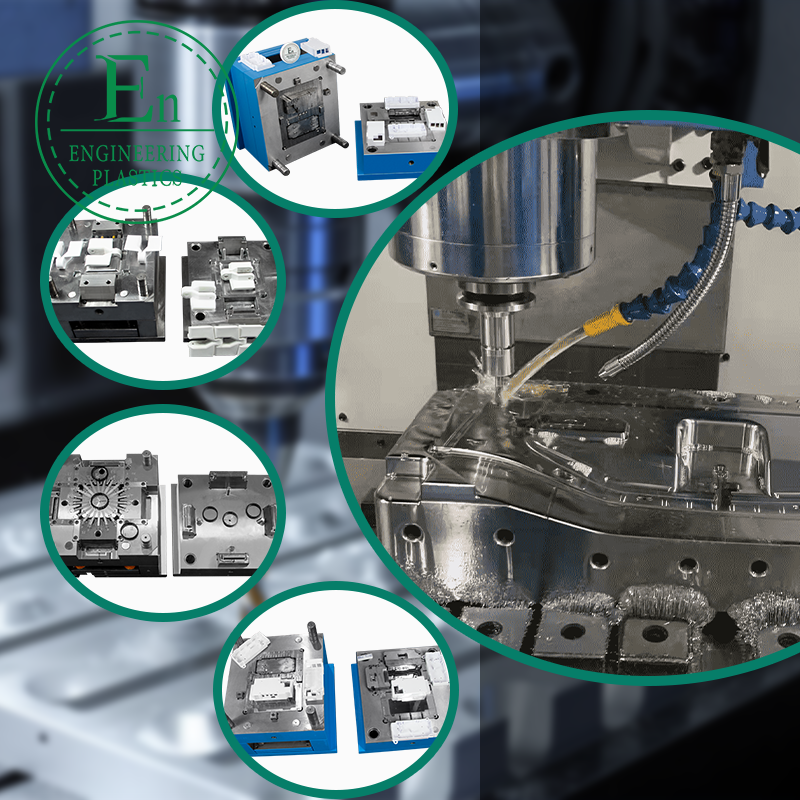

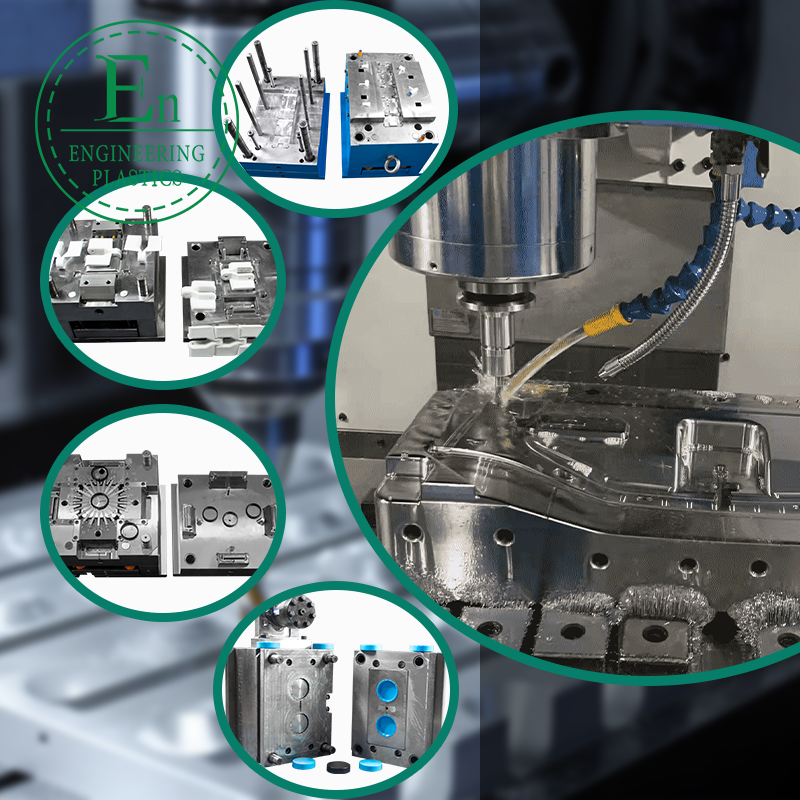

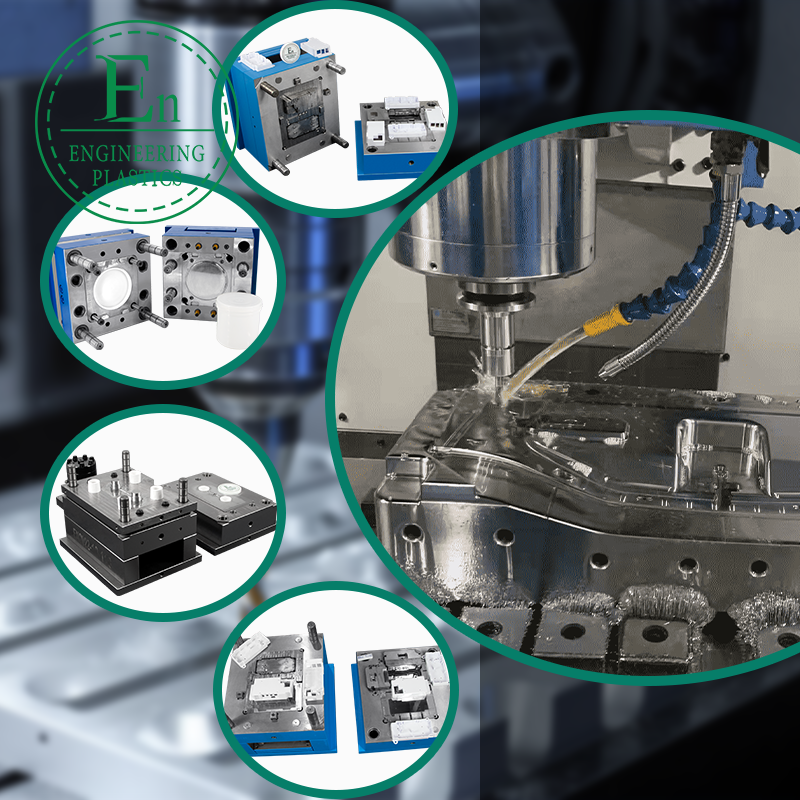

Let's take a deeper look at the specific ABS products that Changshu Sunshine Textile specializes in. Starting with ABS hollow cylinders, these cylinders are precision manufactured to be lightweight yet durable. Hollow cylinders are ideal for applications that require lightweight construction or insulation to maintain structural integrity even in challenging environments. These cylinders can be easily modified to meet specific design needs, making them ideal for different industries.

At the same time, the thick ABS solid slabs offered by Changshu Sunshine Textile open up endless possibilities for engineers and designers. Dimensioned to an accuracy of 2000x1250 mm, these sheets have a perfect surface finish to meet functional and aesthetic needs. Whether you're creating automotive parts, prototypes, or building materials, these solid sheets are materials you can trust. Their ease of processing further adds to their appeal, making them a dream material for those who use machining tools.

The versatility of these ABS products underscores why ABS plastic suppliers are so indispensable in a wide range of industries around the world. These materials have excellent heat deflection temperature and chemical resistance, making them ideal for the most demanding applications. For professionals in industries ranging from heavy machinery to creative manufacturing, ABS materials are a key enabler of innovative products.

Choose the right ABS plastic supplier

When sourcing ABS materials, working with a reliable supplier is essential to ensure quality and performance. Changshu Shentian Textile Co., Ltd. offers a comprehensive range of ABS products, backed by globally recognized certifications such as Oeko-Tex Standard 100 and ISO 9001. Committed to excellence in quality and sustainability, they provide solutions tailored to the modern needs of engineering and manufacturing.

Their ABS hollow cylinders and solid plates are engineered to provide superior durability, stability, and customization options. As a company committed to innovation and customer satisfaction, Changshu Sunshine Textile will continue to build lasting partnerships to ensure the mutual success of all involved. By choosing a trusted ABS plastic supplier, you can easily elevate your project and achieve superior results.

conclusion

In conclusion, ABS plastic products represent the cutting edge of modern materials science, combining strength, versatility, and cost-effectiveness. From hollow cylinders that are ideal for lightweight constructions to solid slabs that are suitable for precision machining, these materials meet a wide range of industrial needs. ABS manufacturing ensures that these products are durable, reliable, and versatile enough to handle the most demanding applications.

With its rich experience and global certification, Changshu Sunland Textile Co., Ltd. is a trusted brand in the ABS plastic industry. Their dedication to quality and sustainability is committed to ensuring that customers around the world have access to quality materials for every project. Whether you're working in automotive, construction, or advanced manufacturing, ABS plastic is the innovative solution you need to overcome modern challenges and bring your designs to life.

So, when you consider an ABS plastic supplier, look to Changshu Sunshine Textile for unmatched quality and service. Your next success story starts with the right materials, and ABS is ready to help you achieve that.