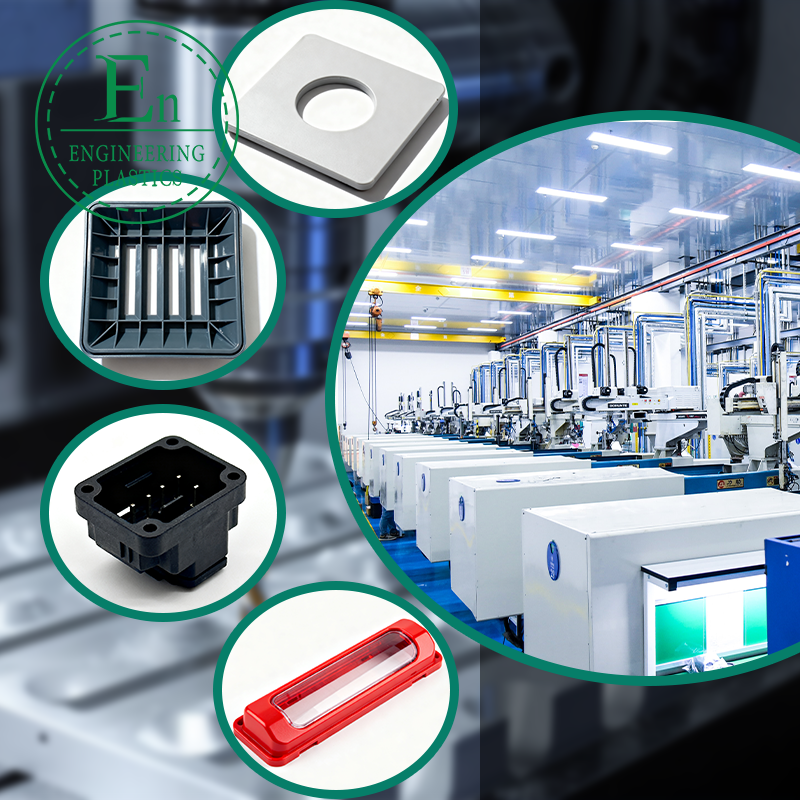

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

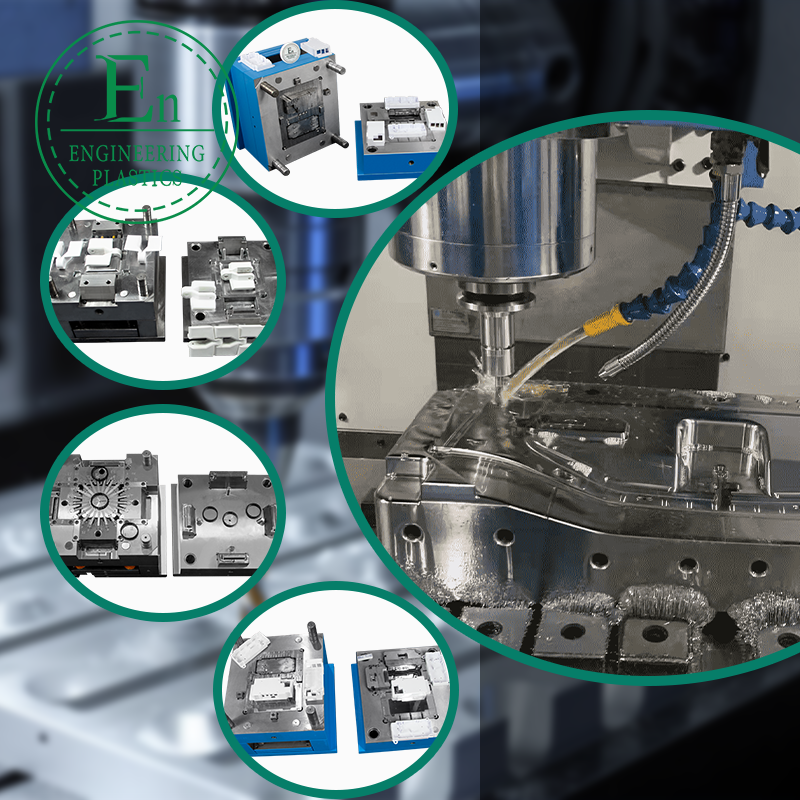

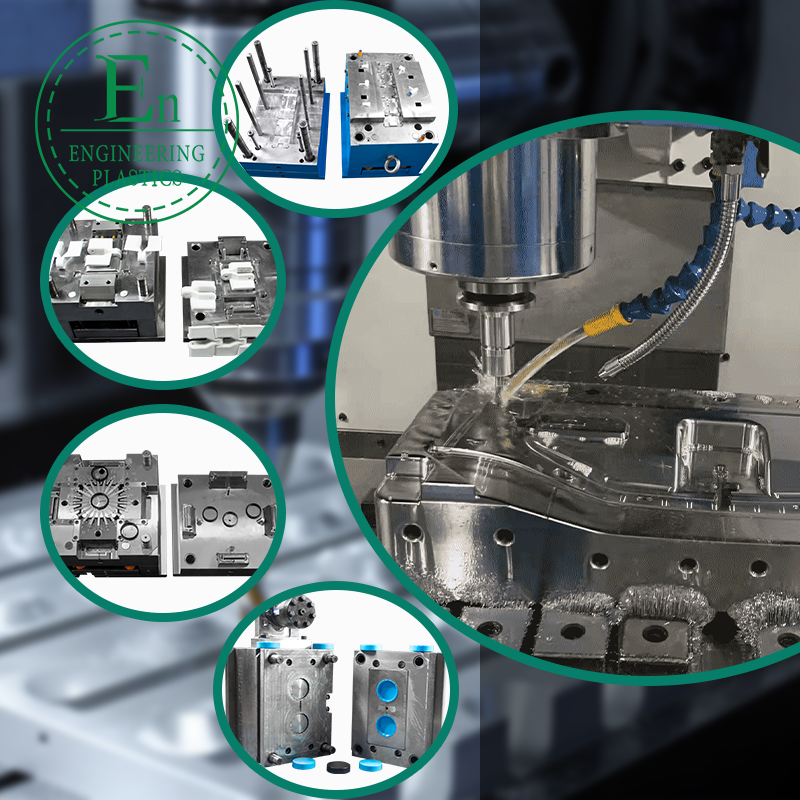

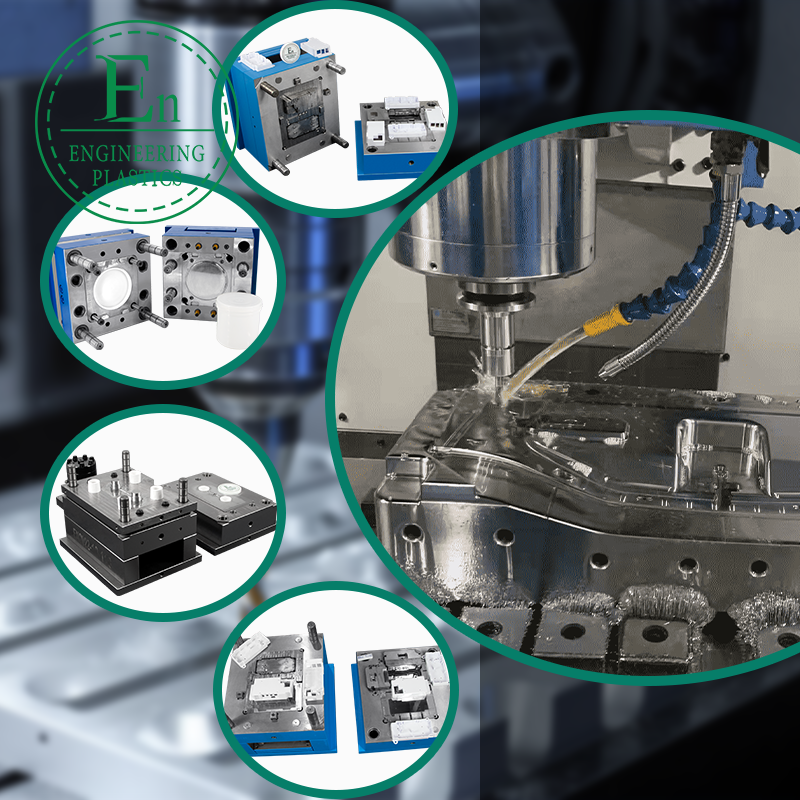

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Understanding Injection Molding Plastic

Injection molding plastic is a versatile and efficient manufacturing process widely employed across industries to produce precise and complex plastic components. This process involves melting plastic material and injecting it into a mold cavity, where it cools and solidifies into the desired shape. Due to its capability to create high-volume products with exceptional accuracy, injection molding plastic is a favored choice for manufacturers globally.

The Injection Mold Process

The injection mold process is an intricate procedure that starts with selecting the right plastic material, such as PEEK, PPS, Nylon, or ABS, depending on the desired properties of the final product. The plastic is then heated to a fluid state and injected into a custom-designed mold, created to precision by professionals like those at Guangdong Engineering Plastics Industries Group Co., Ltd. These molds shape the plastic into specific forms—whether gears, pulleys, sealing rings, or bearings. After the injection, the plastic cools and sets, ready for testing, assembly, and application in various industries.

Choosing the Right Injection Mold Company

Selecting an injection mold company is crucial for achieving high-quality plastic components. A company like Guangdong Engineering Plastics Industries Group Co., Ltd. is an excellent choice because of its proven expertise and global reputation. Their team of senior engineers, with 15-25 years of experience, is capable of offering personalized customization and comprehensive design, research, and development services. This ensures that each product meets precise specifications and quality standards, which is critical for both domestic and international clients. Whether exporting to the USA, UK, Canada, Germany, or other countries, they provide products that embody precision and reliability.

Conclusion

Injection molding plastic remains a critical part of modern manufacturing, and choosing the right company for the job ensures product integrity and satisfaction for end-users. Guangdong Engineering Plastics Industries Group Co., Ltd. stands out with its extensive experience and reputation, providing comprehensive solutions for clients worldwide. Their knowledge in working with diverse materials and creating complex designs makes them a leader in injection molding plastic production.