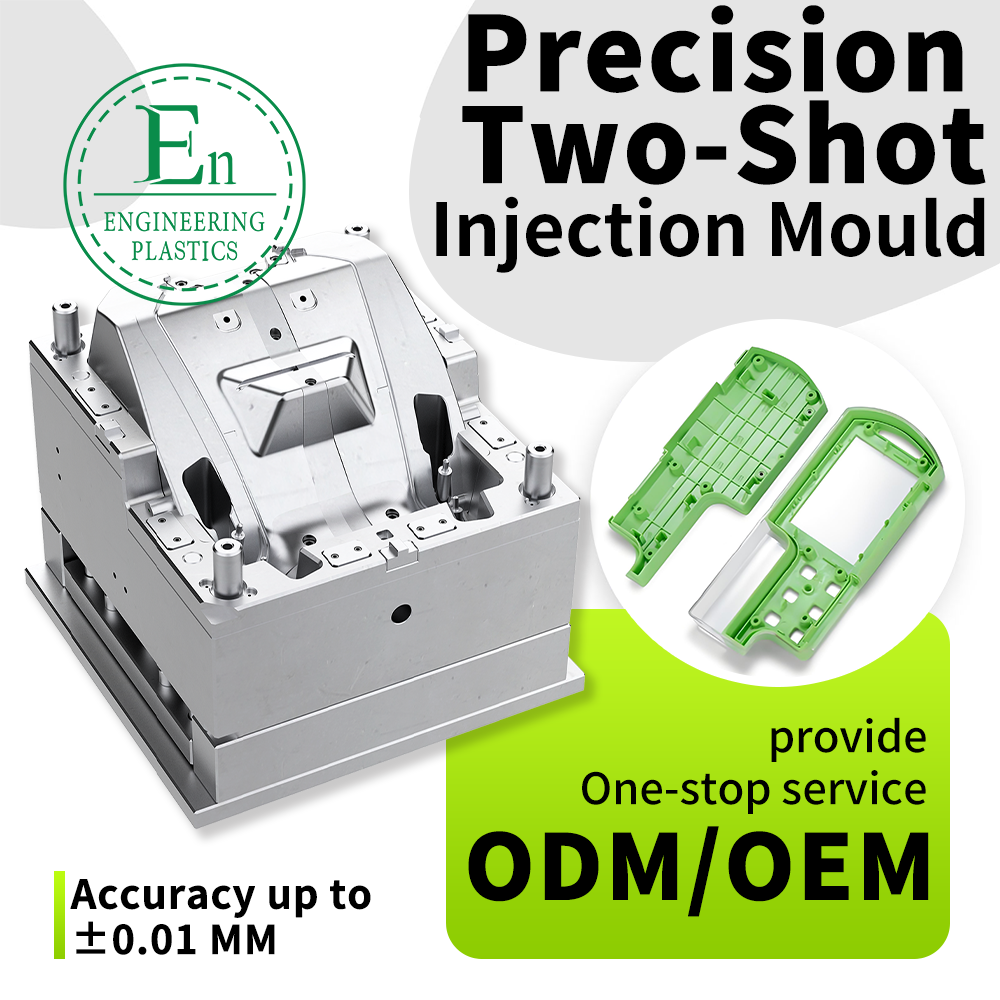

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

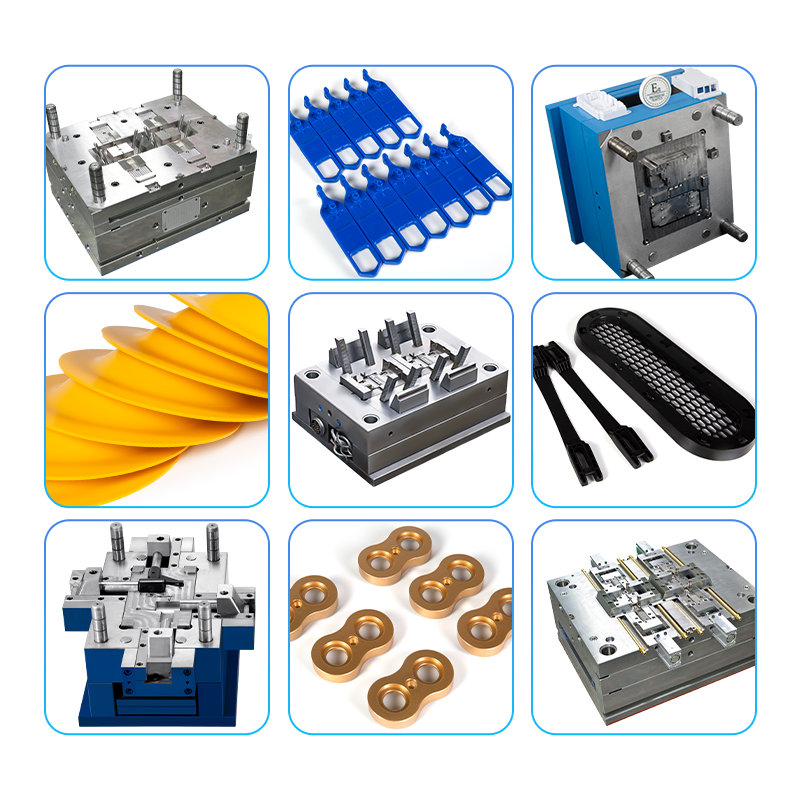

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of modern manufacturing and prototyping, rubber molds have become an indispensable tool for creating detailed and repeatable parts. Their flexibility and durability allow for the production of complex geometries that would be difficult or impossible with rigid molding techniques. A particularly popular material choice for this process is mold silicone rubber, prized for its exceptional properties that cater to both hobbyists and industrial giants alike. Understanding the benefits and processes involved can unlock new possibilities for innovation and production efficiency.

Why Choose Silicone for Your Molds?

One of the primary reasons for the widespread adoption of mold silicone rubber is its incredible combination of flexibility and strength. This elasticity allows for easy demolding of intricate parts with deep undercuts without damaging the mold or the cast piece. Furthermore, silicone boasts high tear resistance, meaning a single mold can be used for numerous casting cycles, making it a cost-effective solution for small to medium production runs. Its chemical inertness and resistance to high temperatures also mean it can be used with a wide variety of casting materials, including resins, waxes, plaster, and even some low-melt metals, without degradation.

The Journey of Creation: Making a Silicone Mold

The process to mold silicone rubber make a finished product is both an art and a science, requiring precision and care. It begins with a master pattern—the original object you wish to replicate. This pattern is secured inside a containment box, and a mold release agent is often applied to ensure easy separation. Next, the two-part silicone compound is carefully measured, mixed, and often placed in a vacuum chamber to remove air bubbles that could compromise the surface detail of the final mold. The liquid silicone is then poured over the master pattern and left to cure, typically for several hours. Once fully cured, the containment box is removed, and the flexible mold is carefully peeled away from the master, revealing a perfect negative impression ready for casting.

Custom Rubber Molds for Engineering Applications

While the process itself is straightforward, achieving the precision required for industrial and engineering applications demands deep expertise. This is where specialized knowledge in materials and design becomes critical. At Guangdong Engineering Plastics Industries Group Co., Ltd., we leverage the power of custom rubber molds to manufacture high-performance engineering plastic components. Our team of senior engineers, with 15-25 years of dedicated experience, excels in developing comprehensive solutions from concept to creation. We utilize advanced molding techniques to produce parts like custom gears, high-tolerance pulleys, and durable sealing rings from materials such as PEEK, PPS, and Nylon, ensuring every product meets rigorous quality standards.

Partnering with Experts for Precision Manufacturing

Ultimately, creating a high-quality product goes beyond just the mold; it requires a holistic understanding of the entire manufacturing process. The right partner can provide invaluable insight into material selection, design for manufacturability, and finishing processes. With a strong global reputation and clients across the USA, UK, Canada, and Germany, our company provides not just manufacturing services, but a collaborative partnership. By integrating our R&D capabilities with our production expertise, we help clients turn their most challenging designs into tangible, high-quality plastic components that drive their industries forward.