We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Understanding the intricacies of a modern injection molding diagram is the first step toward appreciating the precision and expertise required to produce high-quality engineering plastic components. At Guangdong Engineering Plastics Industries Group Co., Ltd., we have transformed this technical schematic into an art form, leveraging decades of experience to deliver components that set new standards for durability and performance. Our process begins with a deep analysis of design requirements, ensuring that every part we produce, from complex gears to simple spacers, is perfectly optimized for its intended application. This commitment to excellence is what defines our approach and establishes us as a leader in the engineering plastics industry.

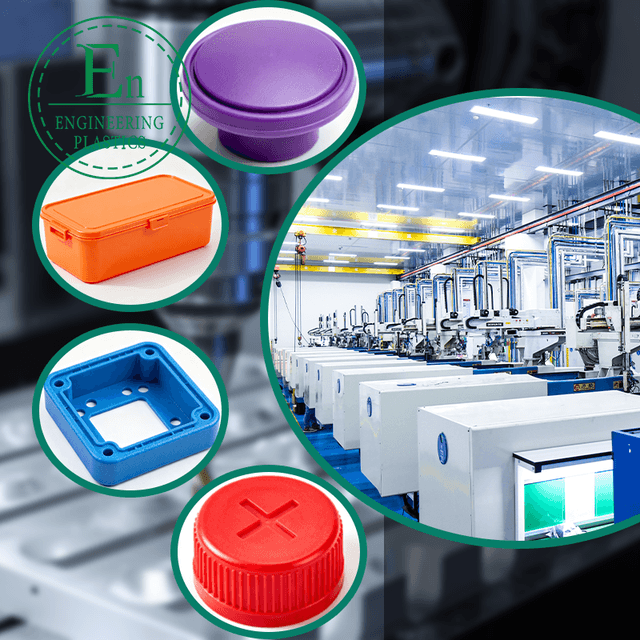

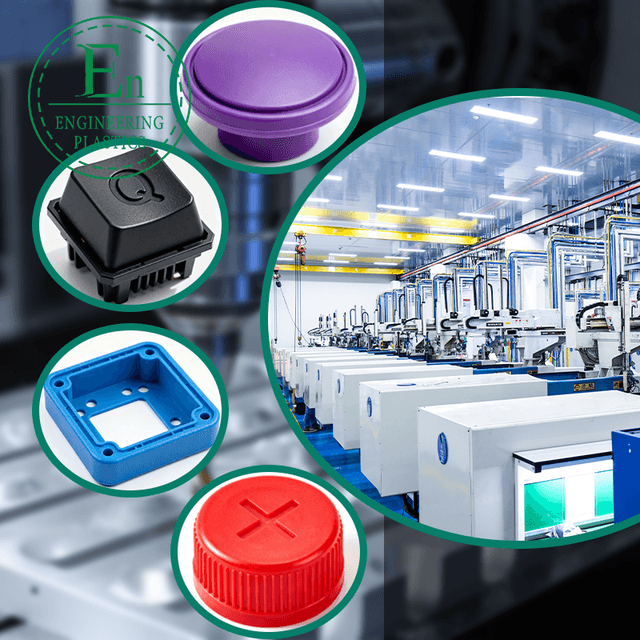

The foundation of any superior molded product lies in its injection molding tooling. This critical stage is where our team of senior engineers, each with 15 to 25 years of dedicated expertise, truly shines. We don’t just manufacture parts; we engineer solutions. The design and fabrication of the tooling demand meticulous attention to detail, as it directly dictates the dimensional accuracy, surface finish, and structural integrity of the final component. Our in-house research and development capabilities allow us to create highly customized injection molding tooling that achieves flawless replication, ensuring that every piece in our Engineering Plastic Component Set, from the vibrant orange gear housings to the ivory alignment brackets, meets exacting specifications for seamless integration and reliability.

Our versatility extends to a wide array of materials, enabling us to tackle diverse and challenging projects. While we specialize in high-performance engineering plastics like PEEK, PPS, Nylon, ABS, and PTFE, our expertise also encompasses advanced processes like injection molding silicone. This capability allows us to produce components such as high-temperature sealing rings and flexible bearings that require the unique properties of silicone, including excellent thermal stability and chemical resistance. Whether a project demands the rigidity of PEEK or the flexibility of injection molding silicone, our comprehensive material knowledge ensures we select the optimal solution to meet and exceed performance expectations, offering a truly holistic manufacturing partnership.

Our Engineering Plastic Component Set is a testament to this integrated manufacturing philosophy. Each component is engineered to provide superior resistance to wear, chemicals, and thermal variations, guaranteeing longevity even in the most demanding industrial environments. The lightweight nature of these plastics facilitates easier handling and assembly without compromising on strength. Furthermore, the use of distinct colors aids in the efficient identification and organization of parts within complex workflows, boosting productivity. Every element is a product of a sophisticated process that starts with a precise injection molding diagram and culminates in a tangible, high-performance solution that adds value to your projects.

At Guangdong Engineering Plastics Industries Group Co., Ltd., our commitment to our clients goes beyond manufacturing. We offer personalized customization, working closely with businesses to design and develop bespoke components tailored to their unique needs. This collaborative approach has earned us a strong global reputation, with a growing list of satisfied clients across the USA, UK, Canada, Germany, and beyond. From initial concept to final production, we provide an end-to-end service that embodies quality, innovation, and reliability. Partner with us to transform your engineering ideals into tangible realities and discover the difference that true expertise makes.