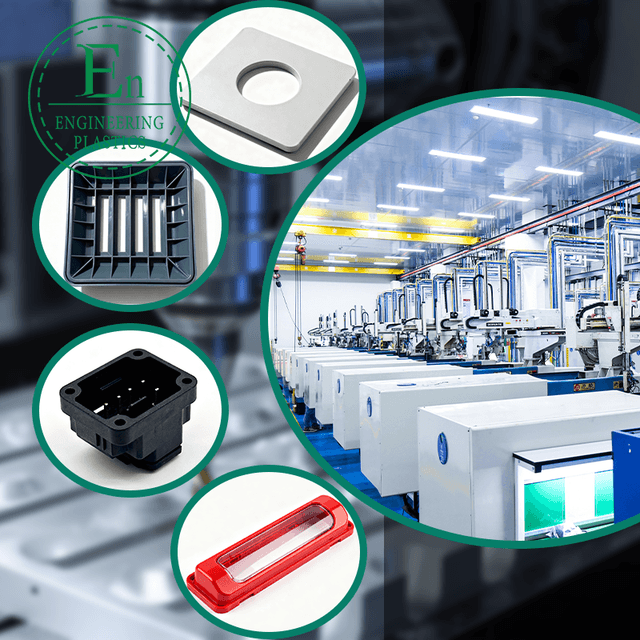

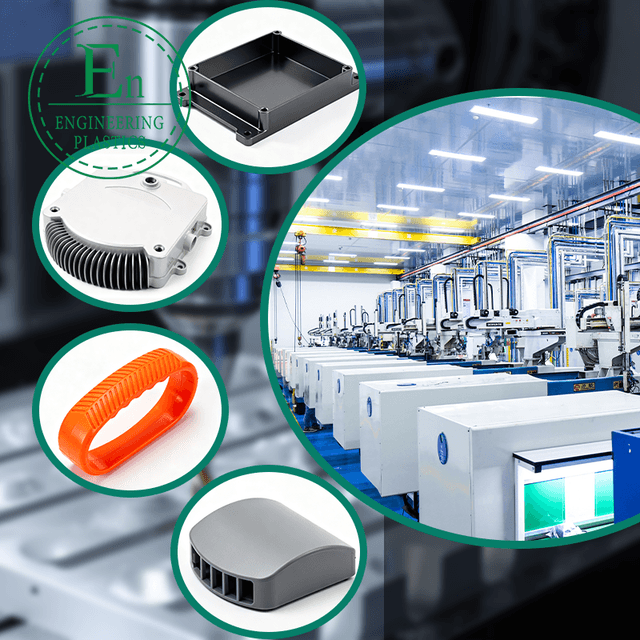

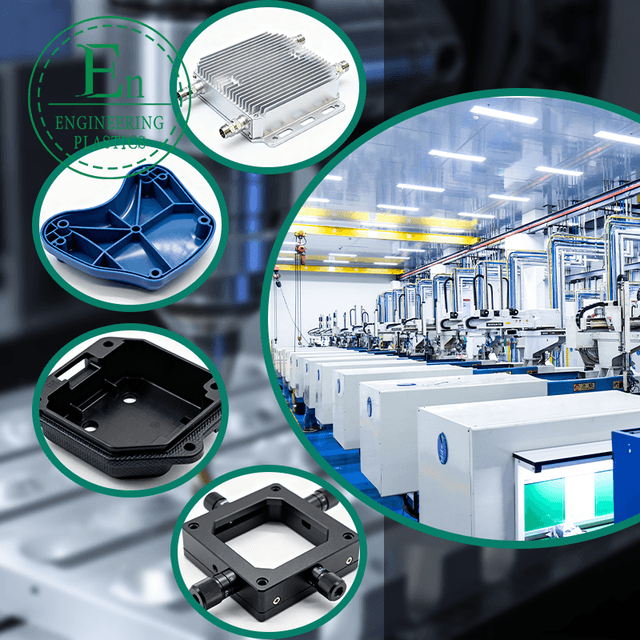

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

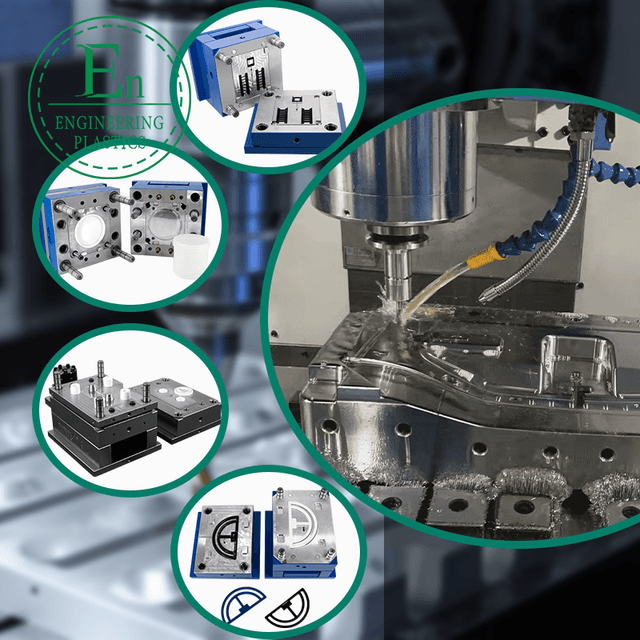

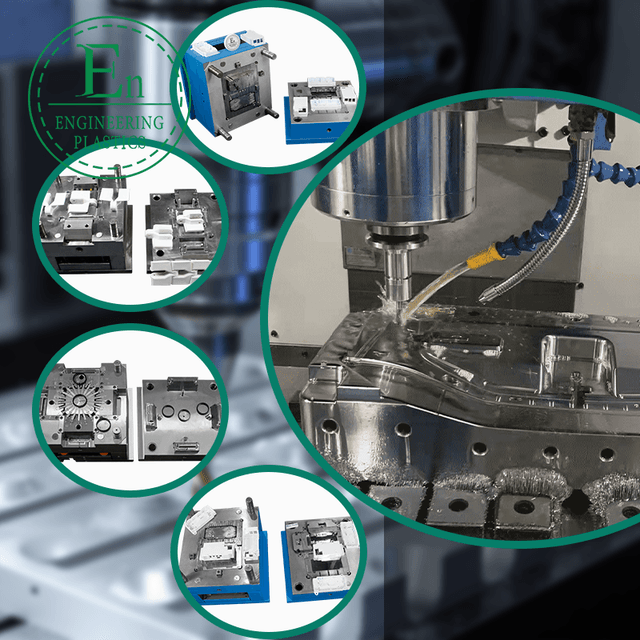

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

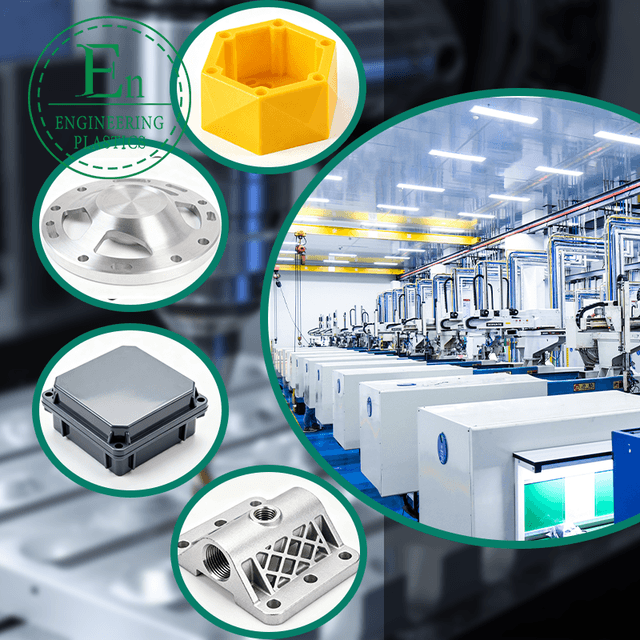

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

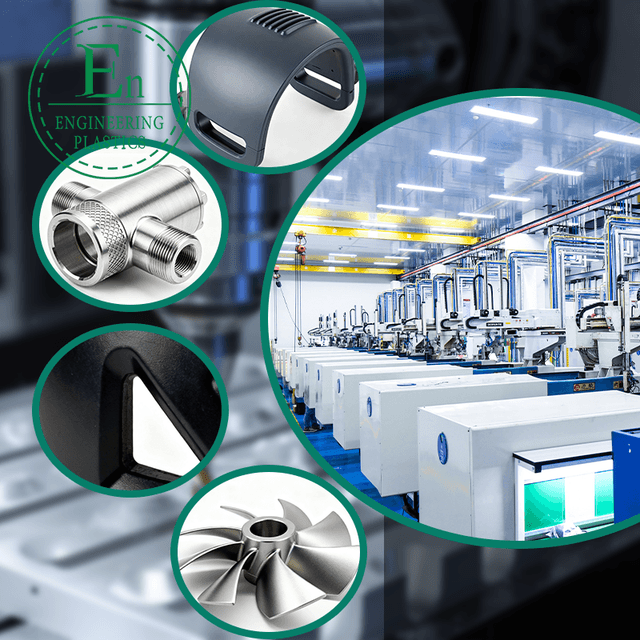

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

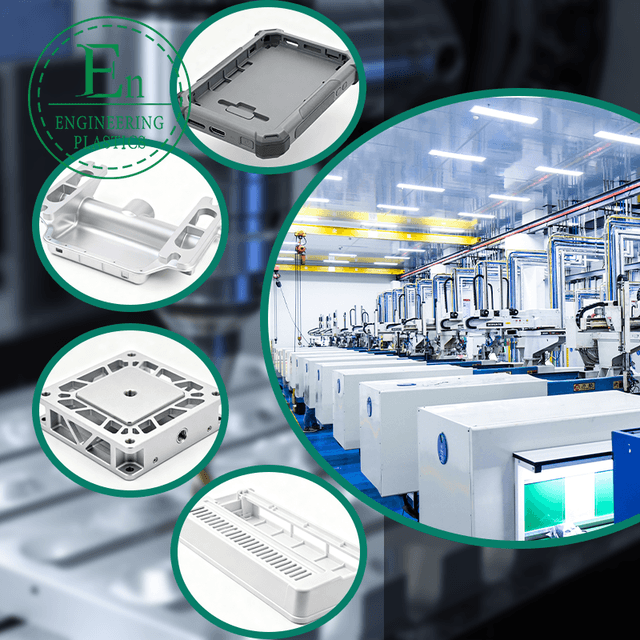

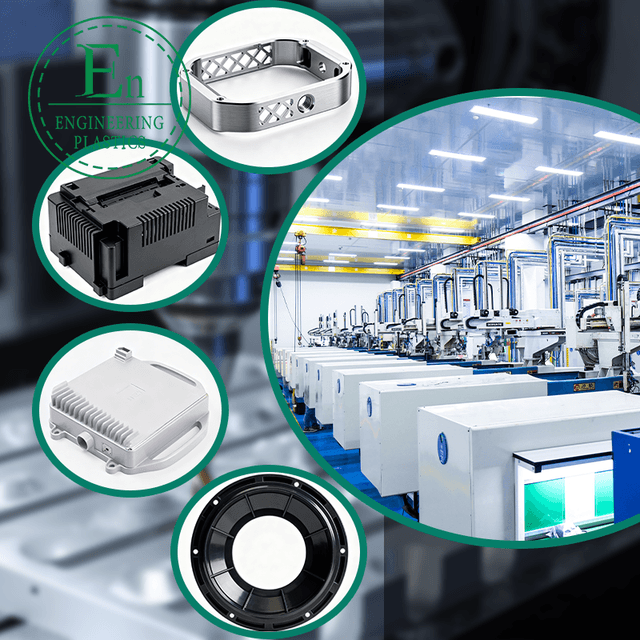

In the world of modern manufacturing, precision and customization are paramount. Our OEM/ODM customized engineered plastic solutions are designed to meet these exacting demands, providing a foundation of reliability and innovation for a multitude of industries. The journey to a perfect component begins with a meticulously crafted stampo a iniezione, a specialized mold that serves as the blueprint for mass production. This critical first step ensures that every single piece, from sleek electronic enclosures to high-tolerance automotive parts, is produced with absolute fidelity to the original design. We are dedicated to transforming your concepts into tangible, high-performance products that not only meet but exceed market expectations, setting a new standard for quality and functional excellence.

The process of stampaggio a iniezione is a sophisticated synergy of science and engineering. It involves injecting molten plastic material into the precision-machined mold cavity under high pressure. Once the plastic cools and solidifies, the mold opens to eject a perfectly formed part. This method is renowned for its incredible efficiency, consistency, and ability to produce highly complex geometries with tight tolerances, details that are impossible to achieve with other manufacturing techniques. Our state-of-the-art facilities harness this technology to its fullest potential, enabling rapid production cycles without sacrificing an ounce of quality. This scalability makes our process ideal for both small-batch prototypes and full-scale production runs, offering a versatile solution for businesses of all sizes.

The versatility of stampaggio a iniezione di plastica allows it to be a cornerstone of innovation across countless sectors. In the automotive industry, our components contribute to creating lighter, more fuel-efficient vehicles without compromising on strength or safety. For consumer electronics, we manufacture stylish and durable housings that protect sensitive internal components while offering a premium tactile experience. Beyond these, our solutions are integral to the medical field for creating sterile, single-use devices, and in consumer goods for everything from kitchen gadgets to power tool casings. Each application benefits from our deep understanding of material properties and design for manufacturability, ensuring the final product is perfectly suited for its intended environment.

Material selection is a critical aspect of our collaborative process. We offer a vast library of engineered polymers, from common plastics like ABS and Polypropylene to high-performance materials that offer exceptional strength, chemical resistance, or temperature stability. Our team of experts works closely with you to identify the ideal material that balances performance requirements, aesthetic goals, and cost considerations. We are also committed to sustainability, offering eco-conscious and recyclable material options that help reduce the environmental impact of your products. This meticulous attention to material science, combined with our cutting-edge manufacturing technology, guarantees that every component delivers uncompromising quality and long-term reliability.

Our business model is built on partnership and collaboration. We are more than just a supplier; we are an extension of your design and engineering team. From the initial consultation to the final delivery, we provide comprehensive support to ensure your vision is realized flawlessly. This collaborative journey includes optimizing your design for the manufacturing process and constructing a custom stampo a iniezione that is built to last and perform to your exact specifications. This dedication to a bespoke service ensures that each product we help create is not just a component, but a competitive advantage in the marketplace.

Ultimately, our mission is to empower innovators by providing the tools and expertise needed to push the boundaries of what's possible with engineered plastics. By choosing to partner with us, you are investing in a process defined by precision, quality, and adaptability. We invite you to configure your designs, optimize your production, and redefine performance with our tailored solutions. Let our expertise in stampaggio a iniezione di plastica be the catalyst for your next breakthrough product, proving that ingenuity and manufacturing excellence go hand in hand.

At the forefront of modern manufacturing, Injection Molding stands as a pivotal process for creating precise, complex, and high-quality components. At En Engineering Plastics, we have honed this technology to an art form, offering cutting-edge solutions that drive innovation across numerous industries. Our commitment is to transform your designs into tangible, high-performance products through a process defined by precision, efficiency, and unwavering quality. We understand that the success of a final product often hinges on the perfection of its smallest parts, which is why our engineering approach integrates state-of-the-art technology with deep material science expertise, ensuring every project we undertake meets the most exacting standards from concept to completion.

Our service is centered around advanced Plastic Injection Molding capabilities, utilizing premium-quality molds meticulously designed for longevity and flawless replication. These molds are the heart of our operation, engineered to accommodate a diverse spectrum of materials and project requirements. We believe that true efficiency is born from a combination of speed and accuracy. Our streamlined processes ensure rapid production cycles without compromising the intricate details or structural integrity of the parts. This focus on operational excellence guarantees that our clients receive top-quality, consistent results with every single order, enabling them to meet market demands with confidence and maintain a competitive edge.

Versatility is key to our Injection Molding services, and our expertise extends across a wide range of thermoplastic materials. For instance, we work extensively with Acrylic, a material celebrated for its exceptional clarity, strength, and aesthetic appeal. This makes it a perfect choice for optical components, consumer product casings, and striking display units. Alongside it, we specialize in molding ABS (Acrylonitrile Butadiene Styrene), which is renowned for its superior impact resistance, toughness, and excellent surface finish. The inherent durability of ABS makes it an ideal material for protective housings, automotive interior parts, and consumer electronics that require a blend of structural integrity and visual appeal.

Beyond common polymers, our capabilities shine in the realm of high-performance engineering plastics. We frequently work with Silicone, a highly versatile elastomer known for its remarkable flexibility, resilience, and stability across a wide temperature range. Its weather and chemical resistance make it perfect for producing durable seals, gaskets, medical-grade tubing, and flexible consumer goods. Furthermore, we handle advanced materials like PSU (Polysulfone). PSU offers a unique combination of high strength, rigidity, and outstanding thermal stability, making it an indispensable material for demanding engineering applications in the medical, aerospace, and water treatment industries where components must withstand harsh conditions and high temperatures without failing.

At the pinnacle of our material offerings is PEEK (Polyether Ether Ketone), an organic thermoplastic polymer that represents the ultimate in performance. Our expertise in the Plastic Injection Molding of PEEK allows us to serve the most demanding sectors, including aerospace, automotive, and medical industries. PEEK offers a phenomenal combination of superb mechanical properties, excellent chemical resistance, and high-temperature performance. This makes it the material of choice for critical components such as lightweight structural parts in aircraft, powertrain components in high-performance vehicles, and implantable devices in the medical field, where biocompatibility and sterilizability are paramount. Our ability to precisely mold PEEK demonstrates our commitment to handling the most challenging engineering projects.

In conclusion, our comprehensive Injection Molding solutions are designed to be a cornerstone of your success. By combining precision engineering, unparalleled material versatility from Acrylic to PEEK, and a steadfast commitment to quality, we position ourselves as more than just a supplier; we are your strategic partner in manufacturing excellence. Our team is dedicated to providing robust, efficient, and innovative solutions tailored to your specific needs. Experience the future of plastic engineering with our unparalleled molding technology and let us help you bring your most ambitious projects to life with precision and reliability.