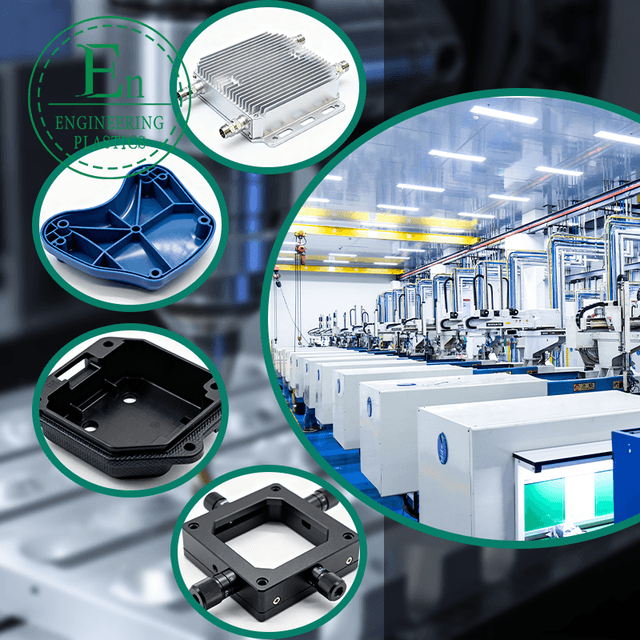

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

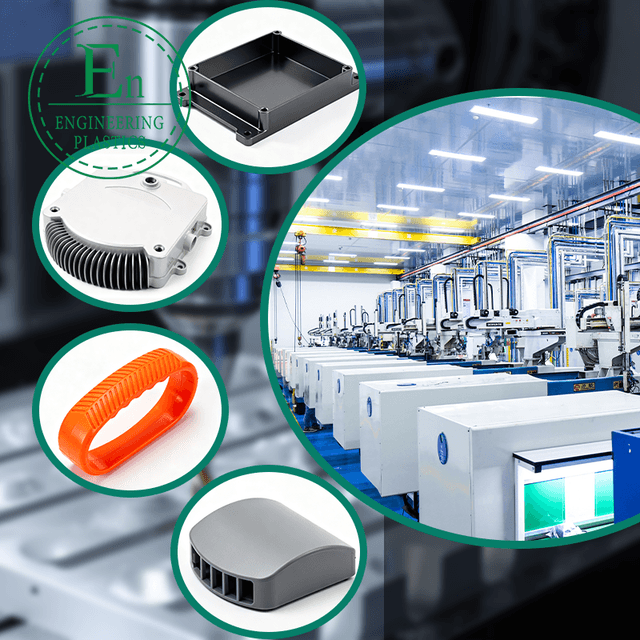

Our expertise includes:

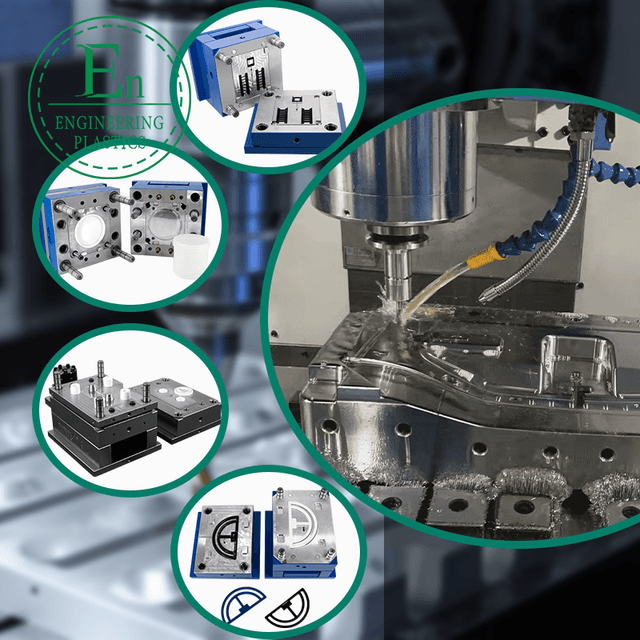

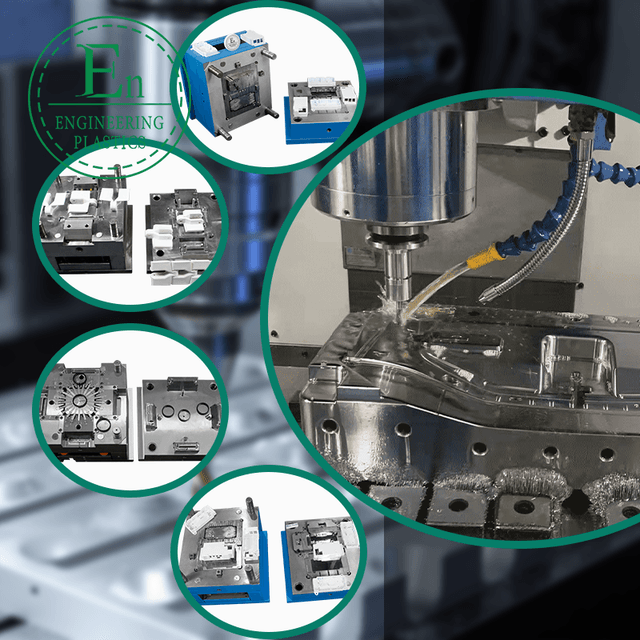

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

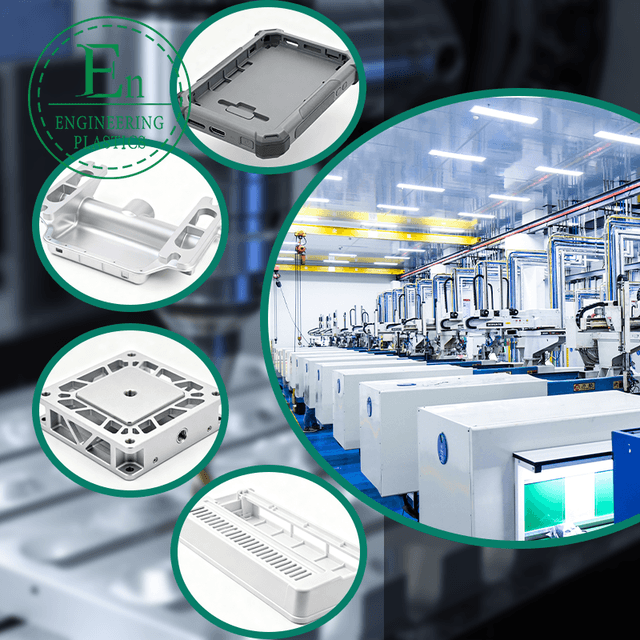

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

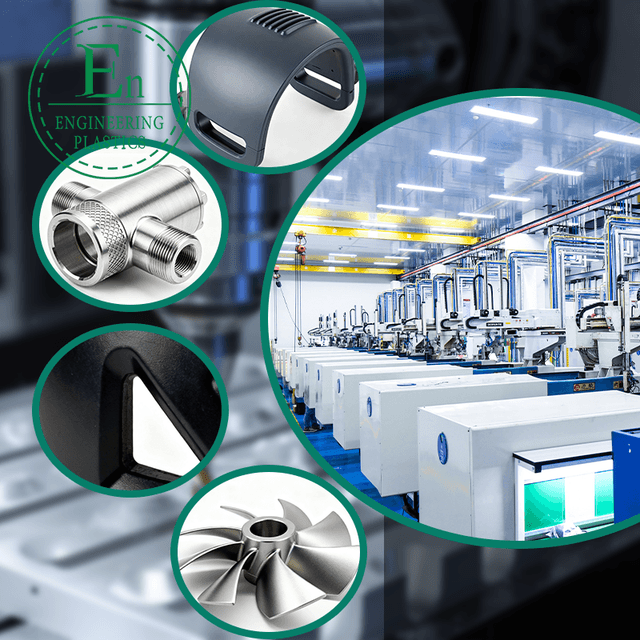

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

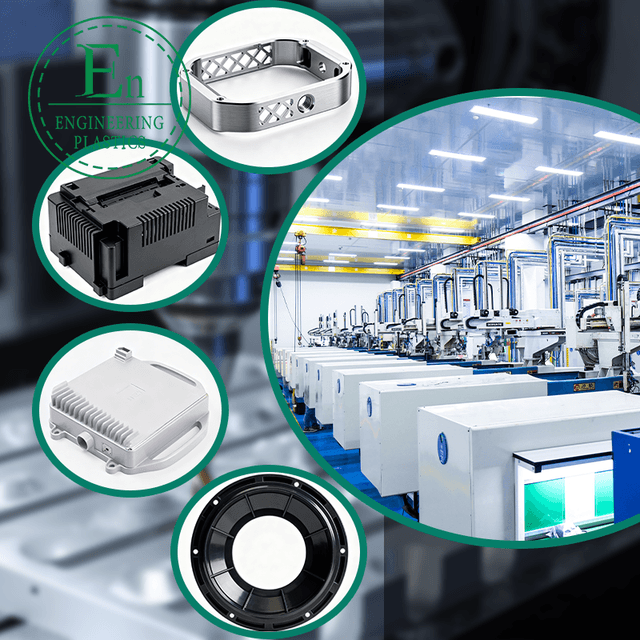

In the realm of advanced manufacturing, the injection moulding mould stands as a cornerstone of precision engineering, enabling the creation of high-quality components that drive innovation across industries. At Guangdong Engineering Plastics Industries Group Co., Ltd., we harness decades of expertise to deliver superior injection moulding mould solutions tailored to your needs. Our senior engineers, with 15-25 years of experience, bring unparalleled design and development capabilities to every project, ensuring that your custom plastic molding injection parts meet the highest standards of durability and performance. Whether you're producing gears, pulleys, or sealing rings from advanced materials like PEEK, PPS, Nylon, ABS, or PTFE, our injection moulding mould technology guarantees efficiency and reliability for global markets, including exports to the USA, UK, Canada, and Germany.

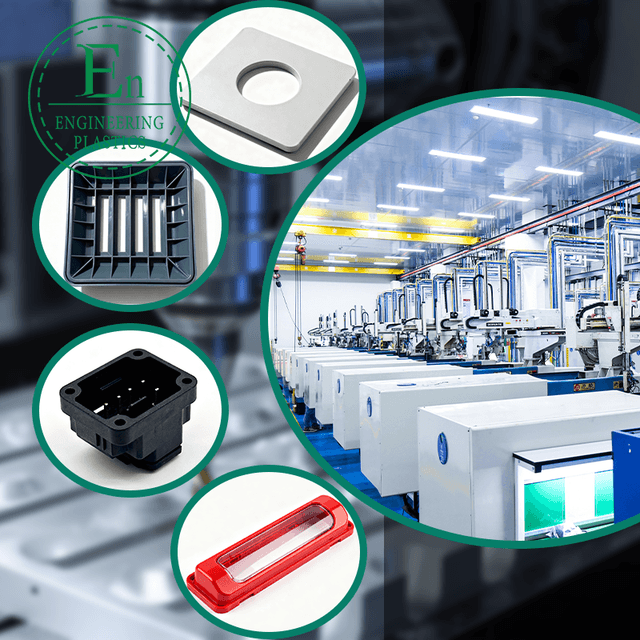

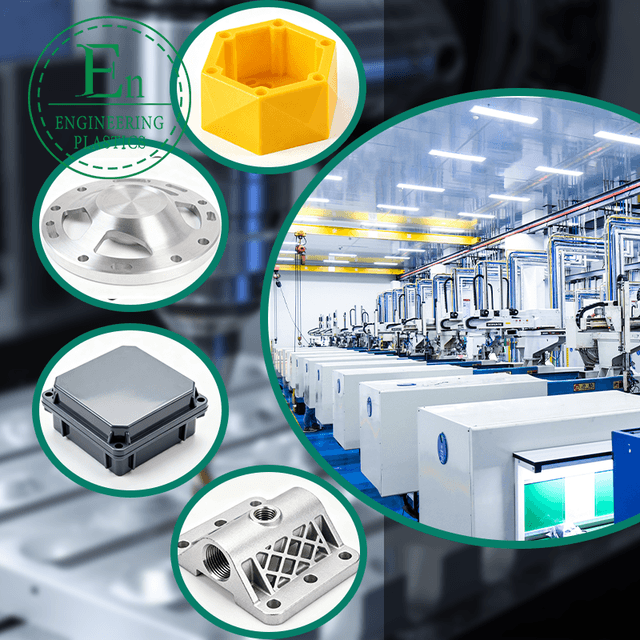

Delving deeper into our offerings, our custom plastic molding injection parts exemplify the perfect blend of versatility and sophistication. These parts are meticulously crafted using state-of-the-art injection moulding mould processes, which allow for impeccable designs that integrate seamlessly with high-tech applications. Imagine a sleek plastic housing that not only enhances aesthetic appeal but also withstands rigorous demands, thanks to our precision techniques that minimize defects and maximize strength. Our assembly lines, powered by cutting-edge innovation, facilitate high-speed production without compromising quality. Each mold injection plastic custom component undergoes rigorous quality checks, ensuring consistency from complex composite structures to intricate mechanical fittings. This harmony between engineering plastics and metallurgy results in resilient products ideal for demanding environments, such as industrial machinery where aerodynamics and material science converge to optimize performance.

What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart is our commitment to personalized customization. Our comprehensive research and development team transforms your concepts into reality, specializing in mold injection plastic custom solutions that cater to diverse applications. From the refined edges of an impeller designed for high-performance motors to robust bearings that reduce friction and enhance longevity, every detail reflects our dedication to perfection. We proudly serve both domestic and international clients, building a strong global reputation through reliable exports and innovative engineering. By choosing our injection moulding mould services, you're investing in a partner that blends functionality with cutting-edge technology, empowering your projects with unmatched precision and efficiency. Our expertise ensures that custom plastic molding injection parts not only meet but exceed expectations, setting new benchmarks in the engineering plastics industry.

As we continue to push the boundaries of manufacturing, Guangdong Engineering Plastics Industries Group Co., Ltd. invites you to explore the transformative potential of our injection moulding mould capabilities. With a focus on sustainability and innovation, we utilize advanced materials to create eco-friendly yet high-performing mold injection plastic custom products. Our team's deep knowledge allows for rapid prototyping and scalable production, making us the go-to choice for industries ranging from automotive to aerospace. Join countless satisfied clients worldwide who have elevated their operations through our tailored solutions, and discover how our injection moulding mould can fuel your next breakthrough in engineering excellence.