We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

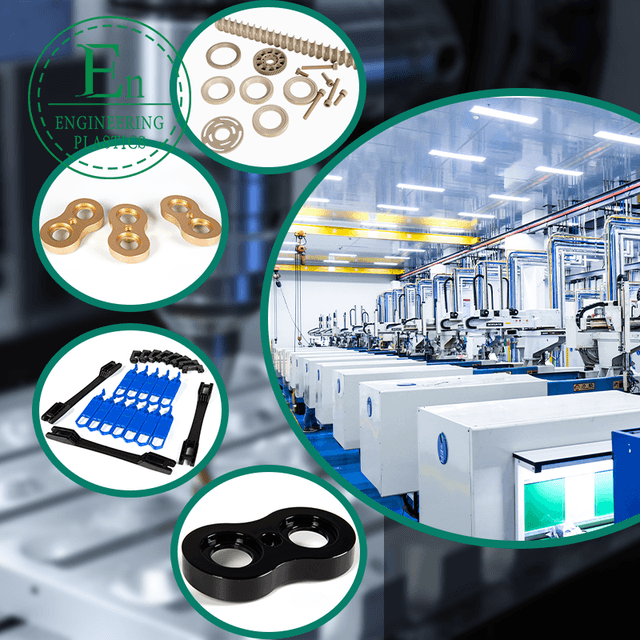

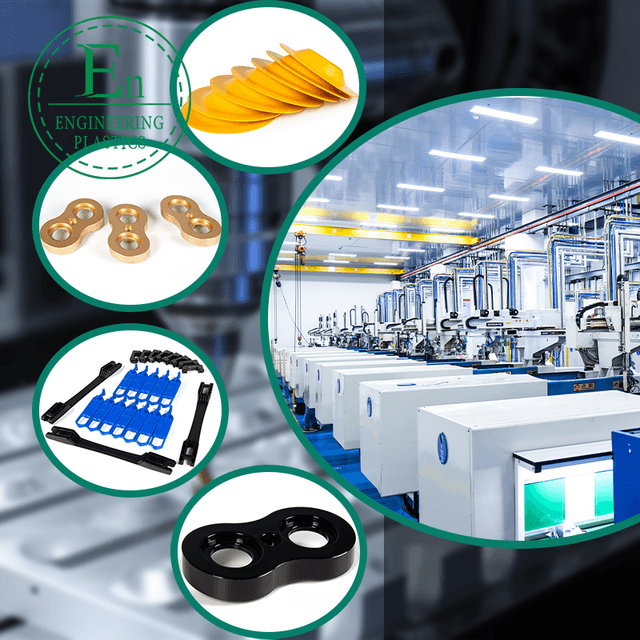

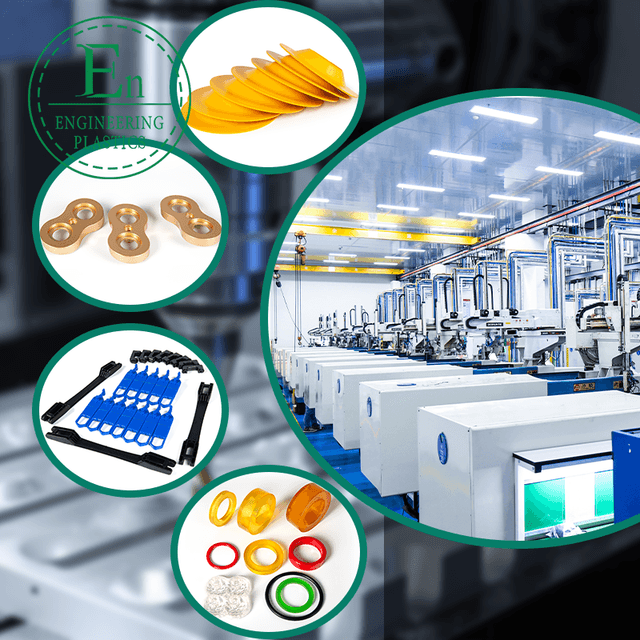

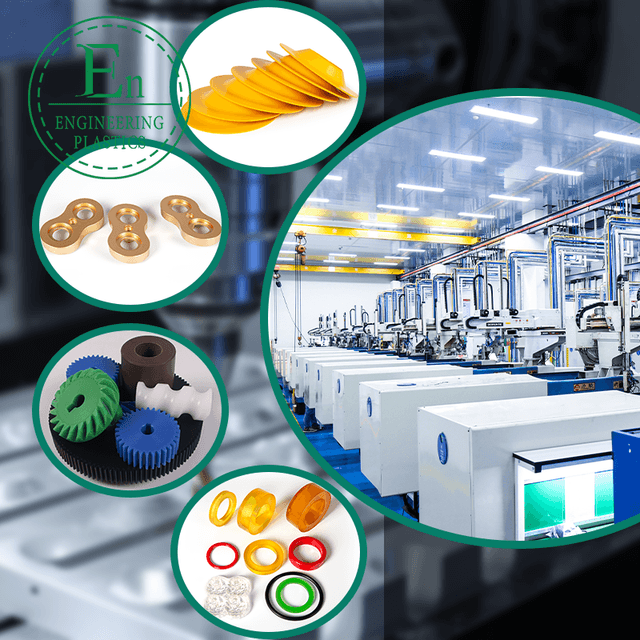

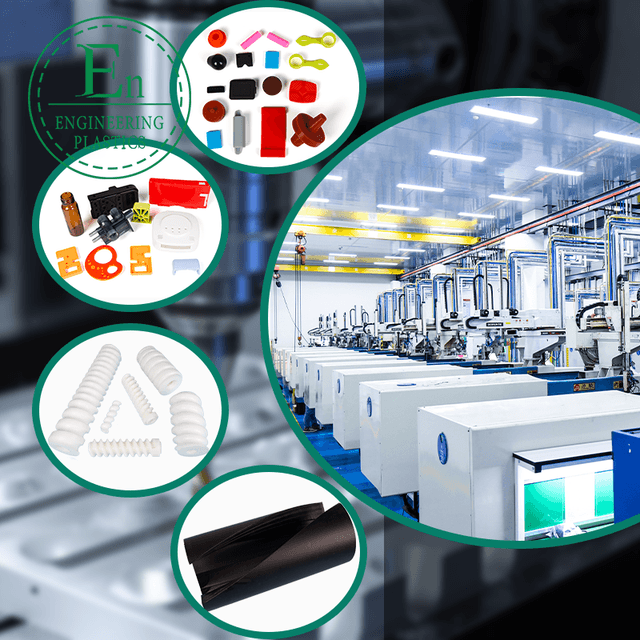

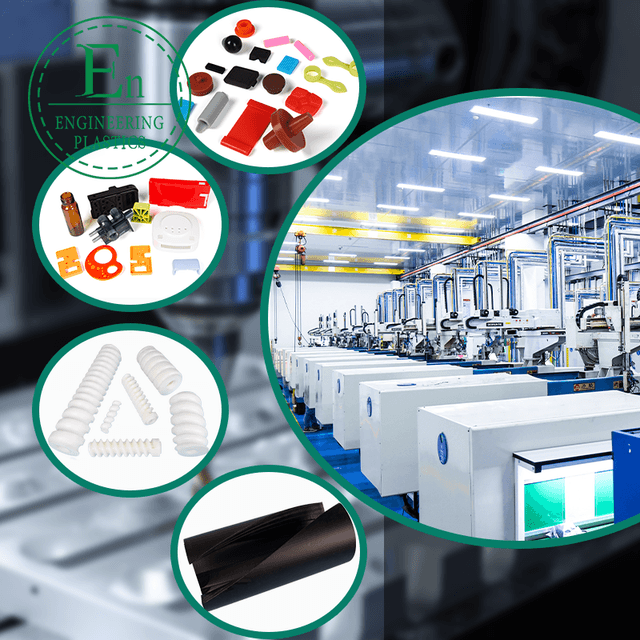

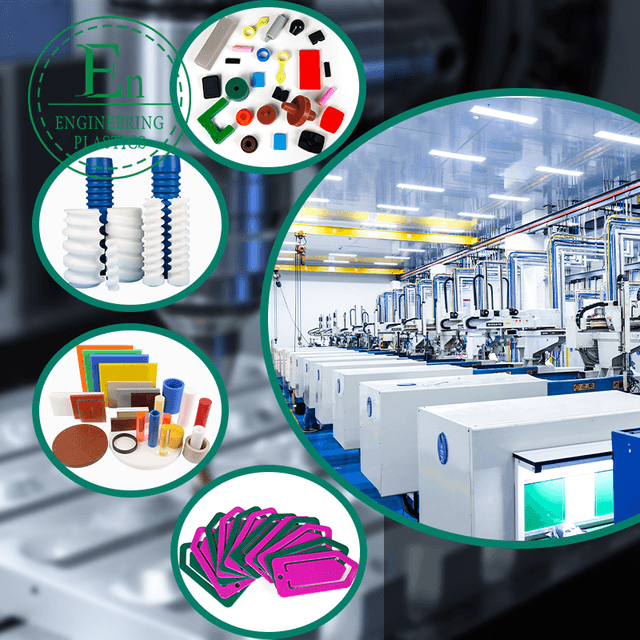

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in transforming complex engineering challenges into tangible, high-performance solutions through our advanced custom plastic injection mold services. In today's demanding industries, from automotive to advanced machinery, the need for components that offer uncompromising precision, durability, and functionality has never been greater. We understand that every project is unique, which is why we focus on delivering bespoke components that are meticulously engineered to meet and exceed the specific requirements of our clients. Our commitment to excellence begins with the very first design consultation and extends through the entire manufacturing process, ensuring that the final product is a perfect fusion of form and function.

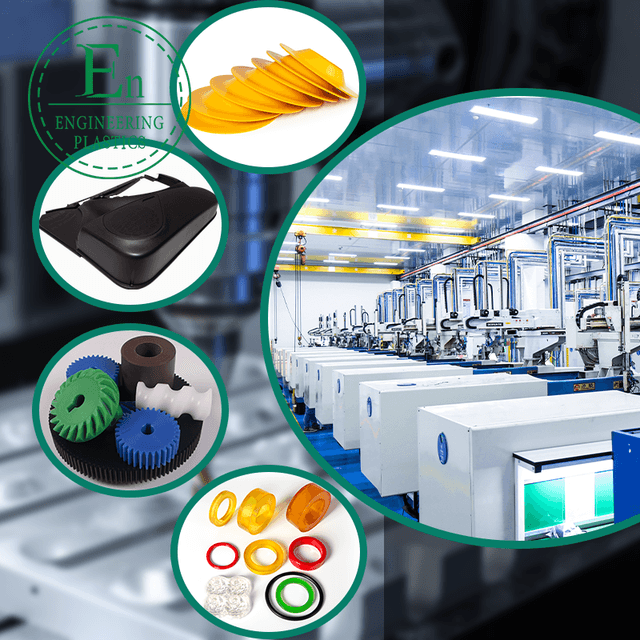

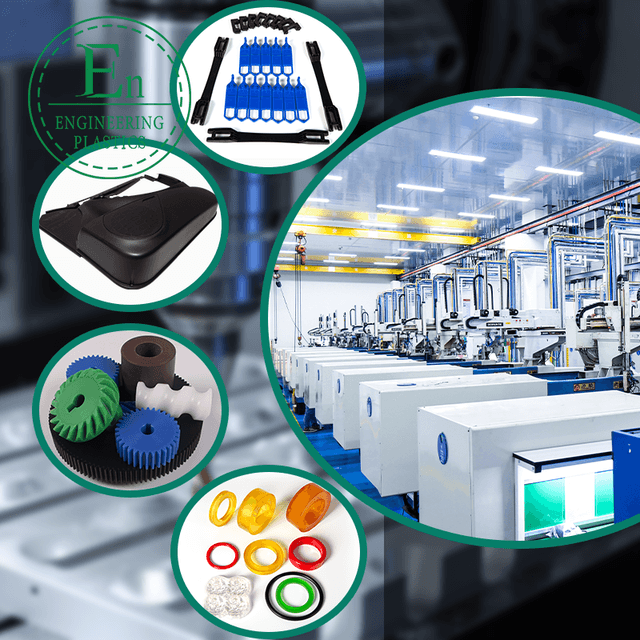

Our reputation as a leading plastic injection mould manufacturer is built upon a foundation of deep expertise and unwavering dedication. Our team is our greatest asset, comprising senior engineers with 15 to 25 years of hands-on experience in the field of engineering plastics. This wealth of knowledge allows us to offer comprehensive services that span from initial concept and design to in-depth research, development, and final production. We don't just create molds; we partner with our clients to provide personalized customization, turning their innovative ideas into reality. Whether it's a complex gear, a high-tolerance sealing ring, or a specialized bearing, our engineering prowess ensures that every component is optimized for performance and longevity.

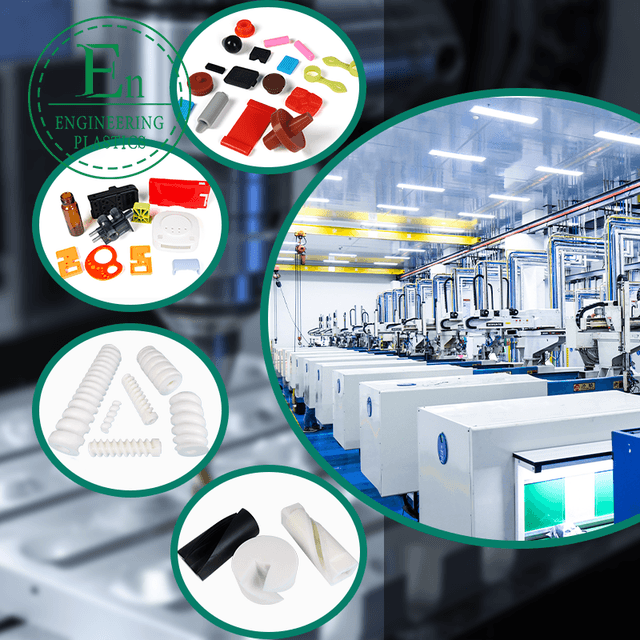

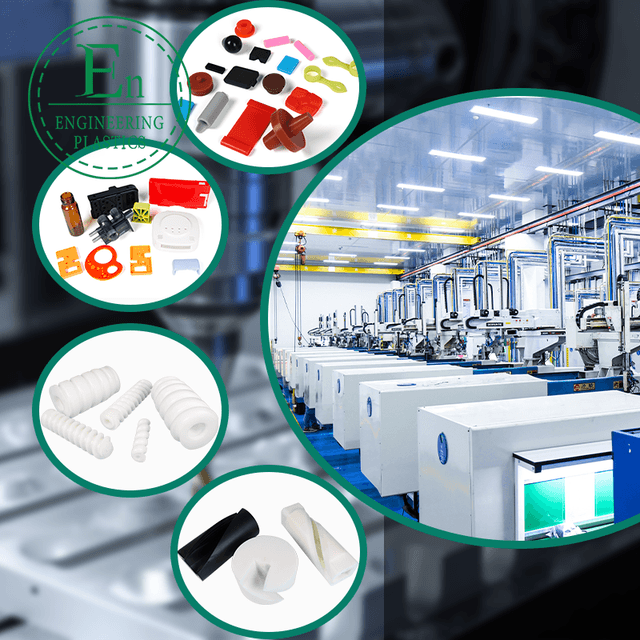

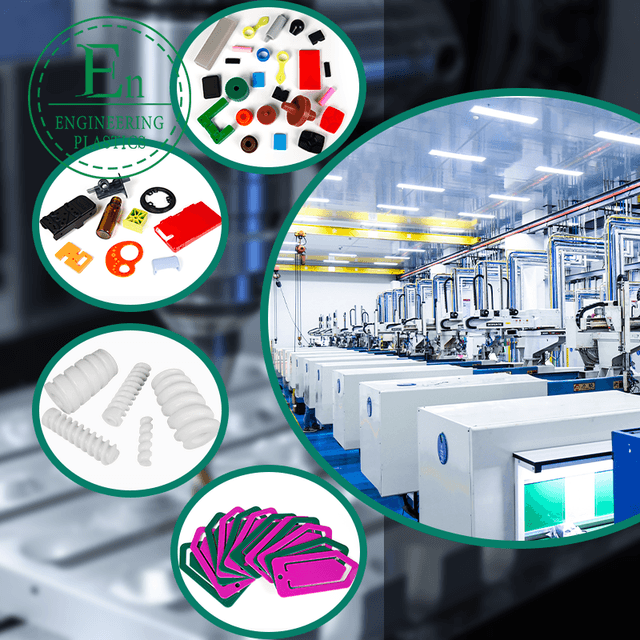

We work with a wide array of high-grade materials, including PEEK, PPS, Nylon, and PTFE, to meet diverse application needs. A significant area of our expertise lies in creating the perfect abs plastic mold for components that require exceptional impact resistance, structural integrity, and a high-quality surface finish. For instance, our dual-chambered black housings are designed to protect sensitive electronics, while our aerodynamic grey shells offer both protection and aesthetic elegance. Components like our precisely calibrated black bases and ergonomic control housings demonstrate our ability to produce intricate parts that integrate seamlessly into larger assemblies. These products showcase the versatility and reliability that an expertly crafted abs plastic mold can provide for critical applications.

The heart of our operation is our state-of-the-art manufacturing facility, a testament to our commitment to precision and quality. This meticulously organized environment is where innovation and technology converge. Every custom plastic injection mold we create is the result of streamlined processes, advanced machinery, and rigorous quality control protocols. We believe that a superior product can only come from a superior manufacturing environment. Our factory layout is designed for efficiency and precision, allowing our skilled technicians and engineers to produce unparalleled products for the modern age. As a distinguished plastic injection mould manufacturer, we invest heavily in our infrastructure to guarantee that every component leaving our facility meets the highest standards of quality and consistency.

Our dedication to quality and innovation has allowed us to build a strong global reputation, serving a diverse international clientele in the USA, UK, Canada, Germany, and beyond. At Guangdong Engineering Plastics Industries Group Co., Ltd., we are more than just a supplier; we are a strategic partner committed to your success. We invite you to experience the difference that true expertise and a commitment to excellence can make. Let us help you revolutionize your next project with future-ready components crafted with precision, dedication, and an unwavering focus on quality. Partner with us to bring your most ambitious engineering plastic designs to life.