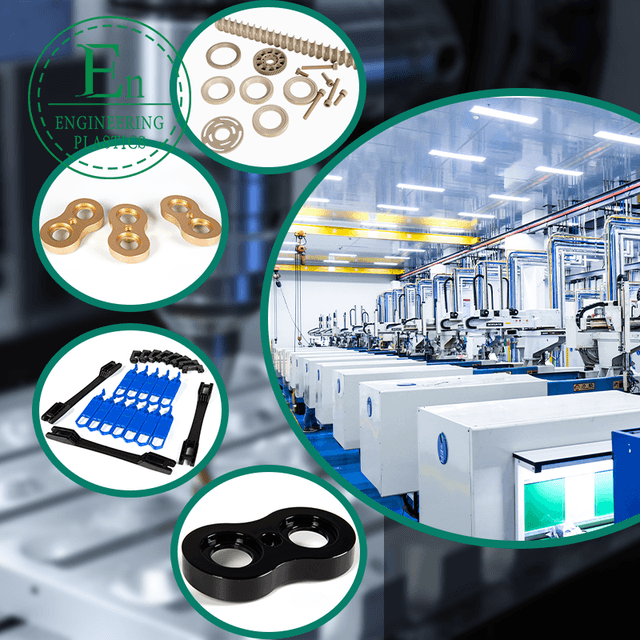

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

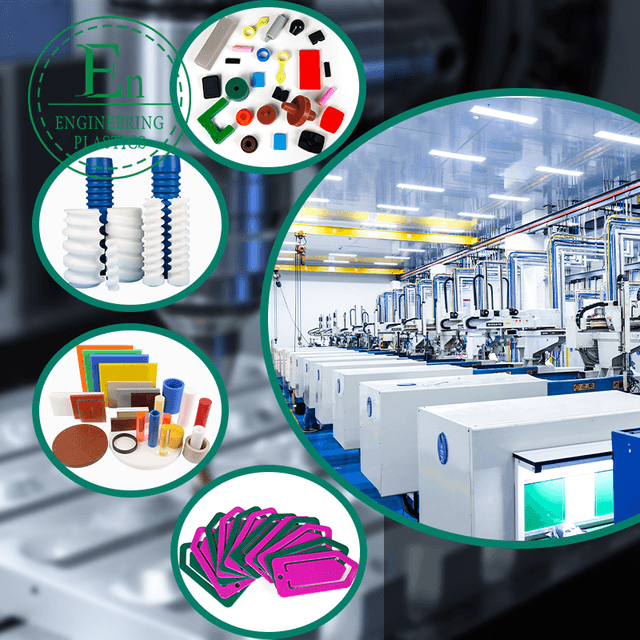

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

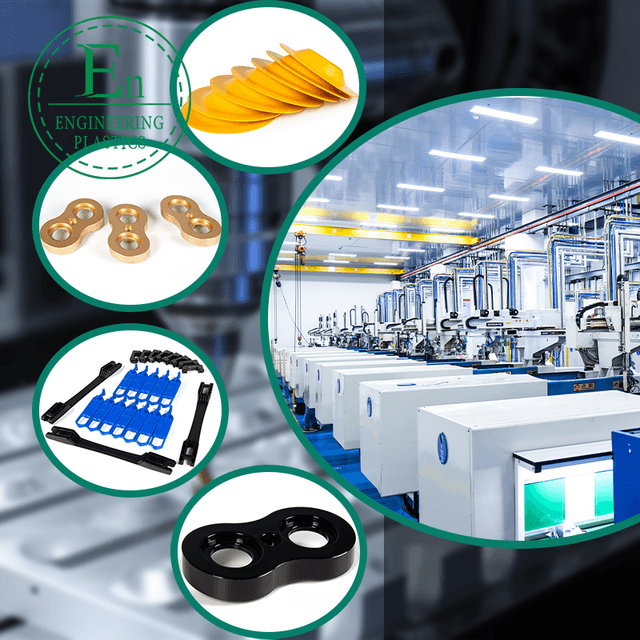

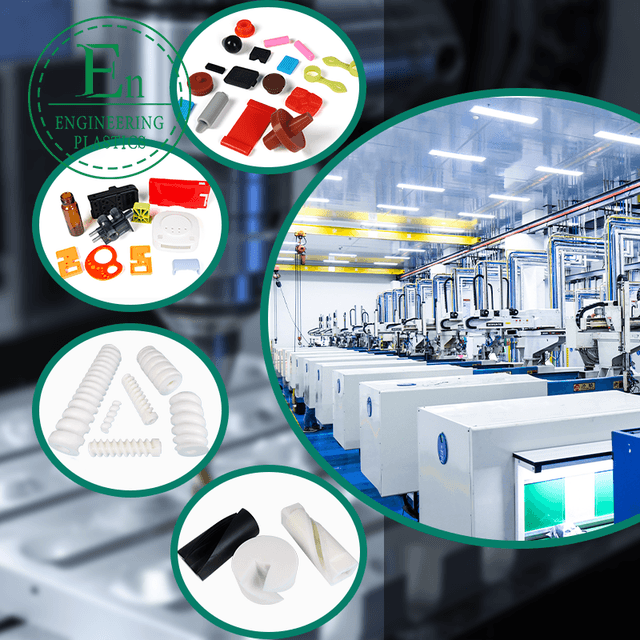

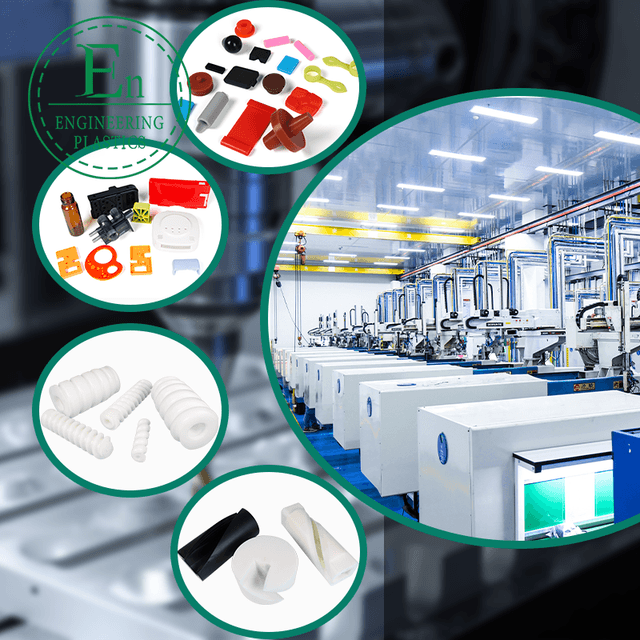

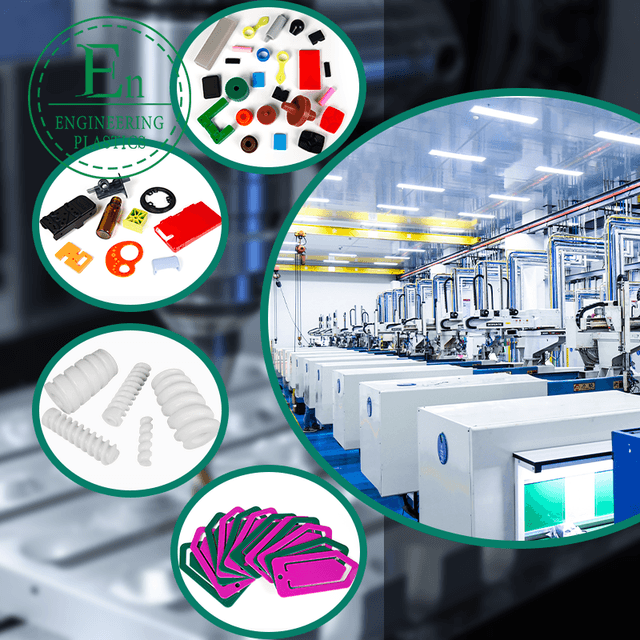

In the world of precision manufacturing, connectors mould stands out as a cornerstone for producing reliable and high-quality engineering plastic components. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting these essential tools that enable seamless integration in various industrial applications. Our connectors mould are designed with cutting-edge technology to ensure accuracy, durability, and efficiency, making them indispensable for industries ranging from automotive to electronics. With a team of senior engineers boasting 15-25 years of expertise, we deliver customized solutions that align perfectly with your project needs, leveraging materials like PEEK, PPS, Nylon, ABS, and PTFE to achieve superior performance.

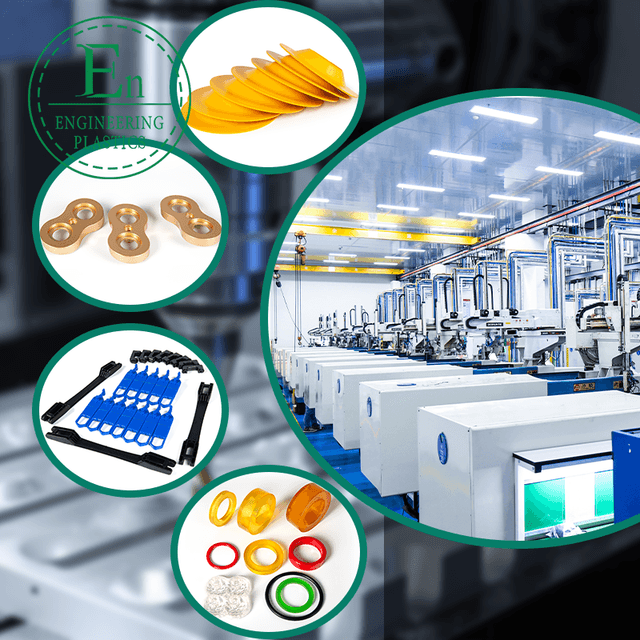

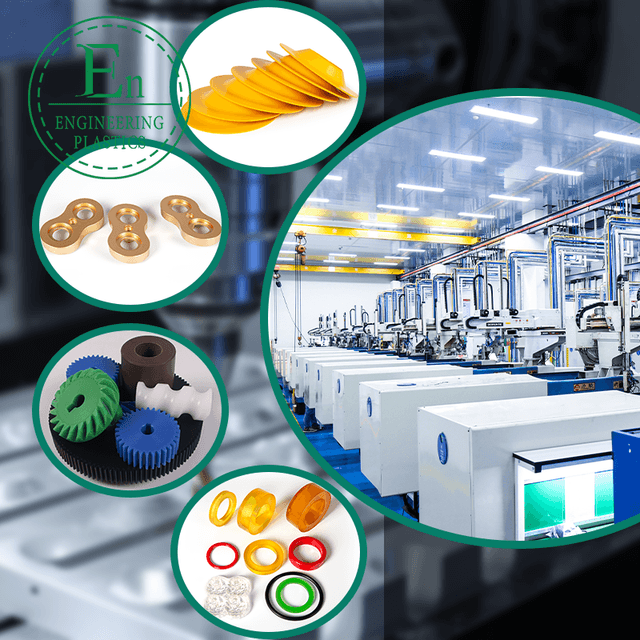

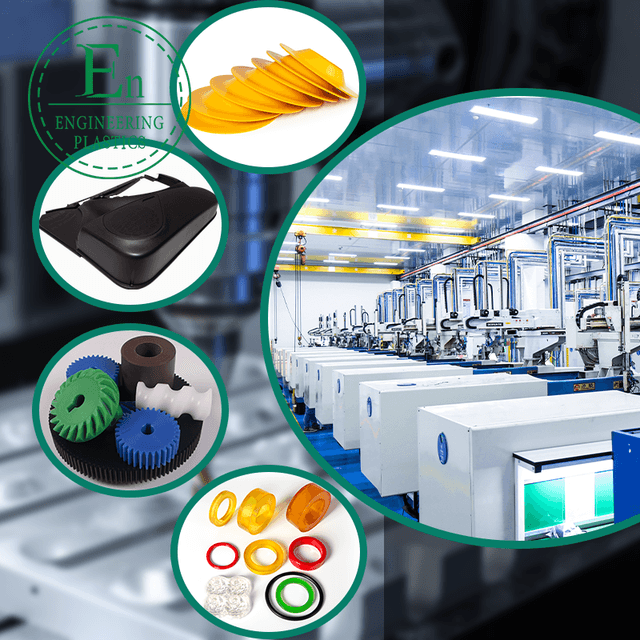

Our extensive manufacturing facility is equipped with state-of-the-art machinery, allowing us to produce connectors mould that meet the highest standards of precision and quality. These moulds are not only robust but also versatile, supporting the creation of vibrantly colored plastic accessories in diverse shapes and sizes. For instance, when paired with plastic bottle molding techniques, our connectors mould facilitate the development of airtight and resilient bottle components ideal for packaging solutions in the beverage and pharmaceutical sectors. This integration ensures that every produced item maintains structural integrity under varying pressures and temperatures, enhancing overall product reliability. Furthermore, our commitment to innovation means that each connectors mould undergoes rigorous testing to withstand high-stress environments, providing long-lasting value to our clients.

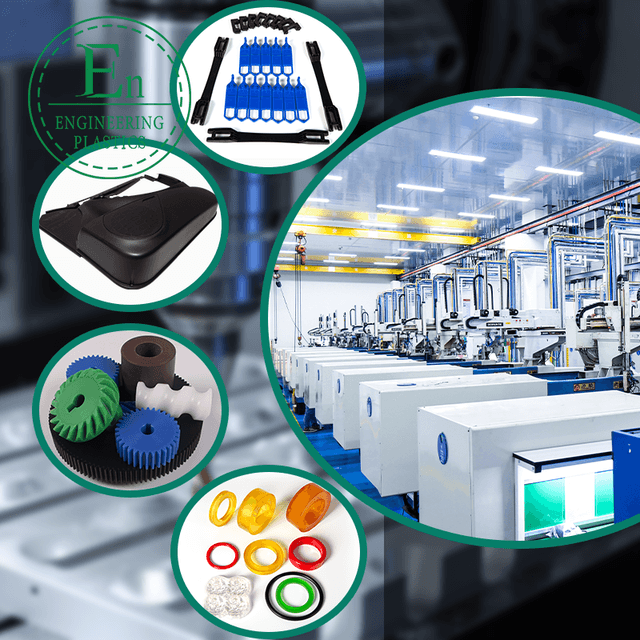

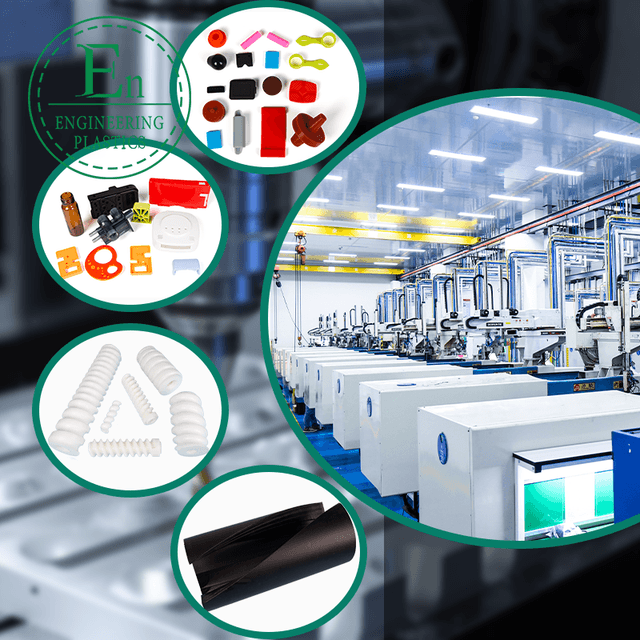

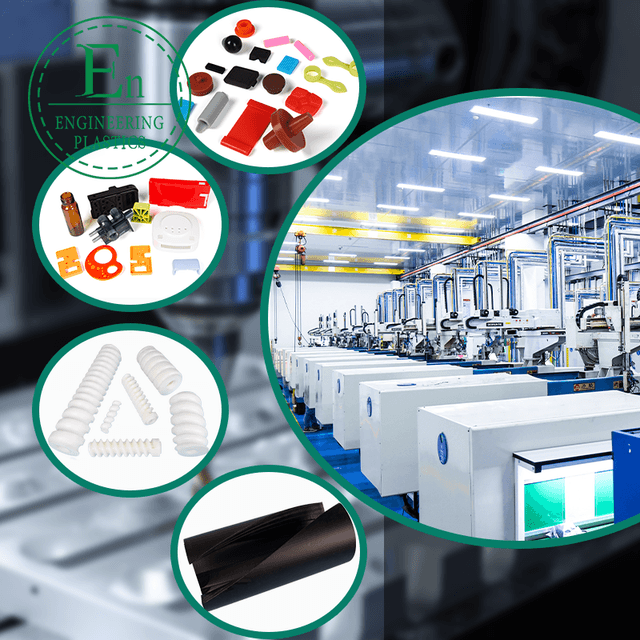

Expanding on our product lineup, plug moulding represents another key area where our expertise shines. Our plug moulding processes complement connectors mould by enabling the fabrication of secure and functional plugs for mechanical, pneumatic, and electronic systems. These plugs, often incorporating spiral and geometric designs, are tailored for optimal functionality in demanding applications such as automotive assemblies and industrial machinery. By utilizing advanced polymer materials, we ensure that plug moulding results in components that resist corrosion, wear, and extreme conditions, thereby extending the lifespan of the end products. Serving a global clientele including exports to the USA, UK, Canada, Germany, and beyond, Guangdong Engineering Plastics Industries Group Co., Ltd. has built a strong reputation for delivering engineering plastics that solve modern industrial challenges with precision and reliability.

Beyond just manufacturing, our comprehensive design, research, and development capabilities allow for personalized customization in both connectors mould and plastic bottle molding projects. Whether you're seeking gears, pulleys, sealing rings, bearings, or specialized plugs through plug moulding, our diverse range of engineering plastic products is engineered for versatility and resilience. We take pride in our ability to offer end-to-end solutions, from initial concept to final production, ensuring that every piece aligns with your specific engineering requirements. This holistic approach not only boosts efficiency but also reduces costs for our international partners, solidifying our position as a trusted leader in the field.

As we continue to push the boundaries of engineering plastics, our connectors mould and related offerings like plastic bottle molding and plug moulding are poised to drive innovation across sectors. Explore how Guangdong Engineering Plastics Industries Group Co., Ltd. can elevate your projects with our high-performance components, backed by decades of expertise and a global reach. Precision, innovation, and quality are at the heart of everything we do, making us the ideal partner for your next industrial endeavor.