We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the dynamic world of automotive manufacturing, the automotive mold stands as a cornerstone for producing high-precision components that drive innovation and reliability. At Guangdong Engineering Plastics Industries Group Co., Ltd., we leverage our expertise in engineering plastics to craft automotive molds that meet the rigorous demands of the industry. With a team of senior engineers boasting 15-25 years of experience, we deliver personalized customization, from design to final production, ensuring every mold aligns perfectly with your specifications. Our state-of-the-art facility employs advanced techniques to create molds that enhance efficiency and durability in automotive applications.

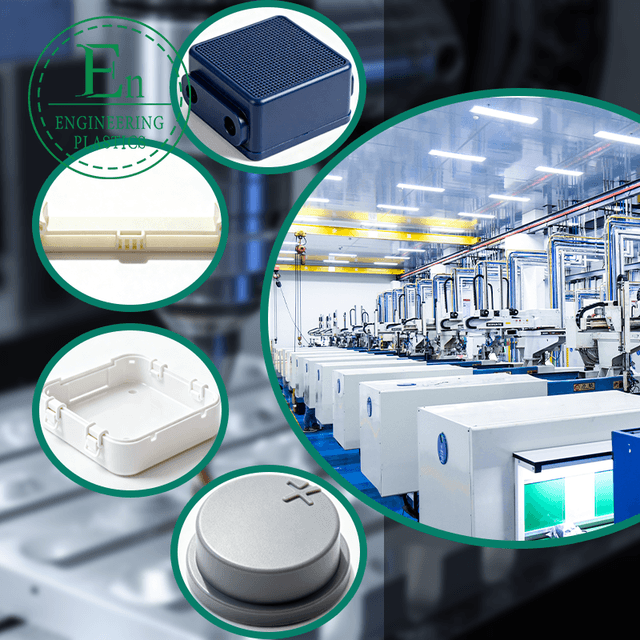

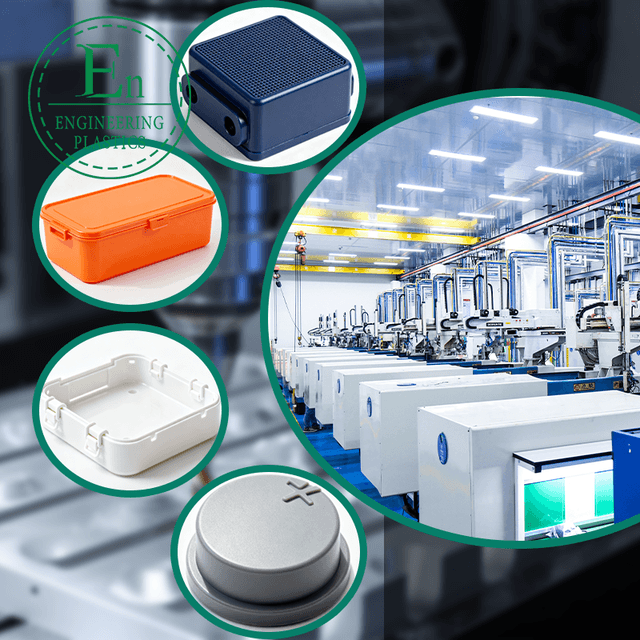

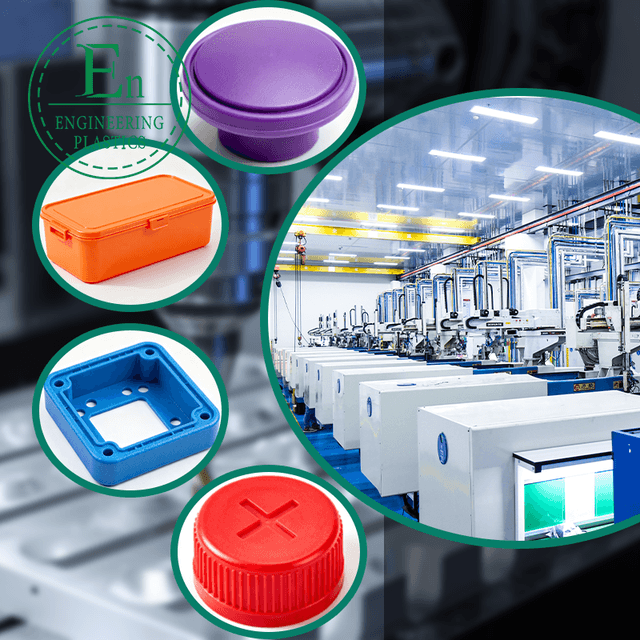

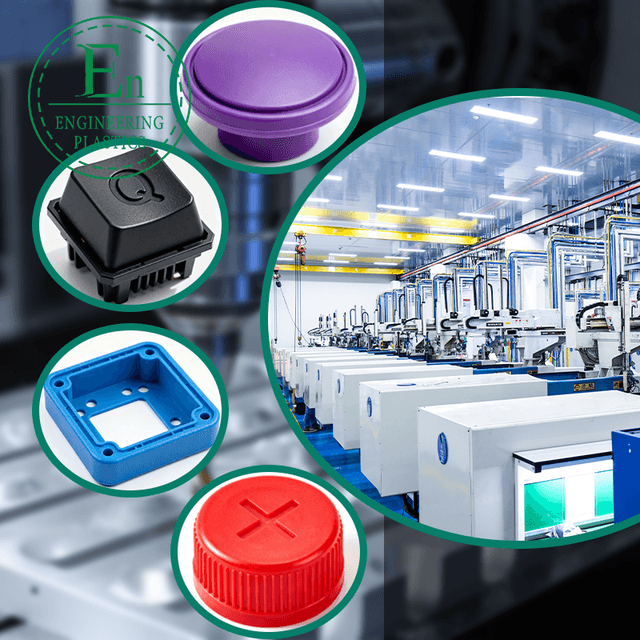

Delving deeper into our offerings, our automotive molds are integral to producing injection molded cases that provide robust protection for sensitive automotive parts. These injection molded cases are engineered using premium materials like PEEK, PPS, Nylon, ABS, and PTFE, offering exceptional resistance to heat, chemicals, and mechanical stress. Whether for engine components or electronic housings, our injection molded cases ensure a seamless fit and long-lasting performance, reducing downtime and maintenance costs. Similarly, the injection mold case variants we specialize in focus on precision molding for compact, versatile enclosures that safeguard wiring and sensors in vehicles. This attention to detail stems from our comprehensive research and development capabilities, allowing us to tailor solutions that exceed industry standards.

Our commitment to excellence extends to the global stage, as we export these high-quality automotive mold products to clients in the USA, UK, Canada, Germany, and beyond. Take, for instance, our purple component, which exemplifies vibrant design integrated with robust construction—ideal for custom automotive mold applications where aesthetics meet functionality. The orange container we produce serves as a practical storage solution via injection molded cases, built to endure harsh automotive environments while ensuring easy access and secure containment. Our white casing represents cutting-edge housing technology, perfect for injection mold case designs that encapsulate components in diverse vehicle systems. Finally, the silver cap highlights precision engineering, providing reliable coverage in mechanical assemblies crafted through our automotive mold expertise.

What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart is our holistic approach to manufacturing. We don't just produce molds; we create partnerships that foster innovation in the automotive sector. Our wide range of products, including gears, pulleys, sealing rings, and bearings, complements the automotive mold lineup, offering one-stop solutions for your engineering needs. By prioritizing quality control and sustainable practices, we ensure that every injection molded case and injection mold case not only performs flawlessly but also contributes to eco-friendly automotive advancements. With a proven track record of serving international markets, we invite you to experience the reliability and versatility of our automotive mold solutions. Whether you're developing next-gen electric vehicles or refining traditional engines, our products are designed to accelerate your success. As we continue to push the boundaries of engineering plastics, Guangdong Engineering Plastics Industries Group Co., Ltd. remains your trusted partner in automotive innovation, delivering precision, durability, and unmatched customization every time.