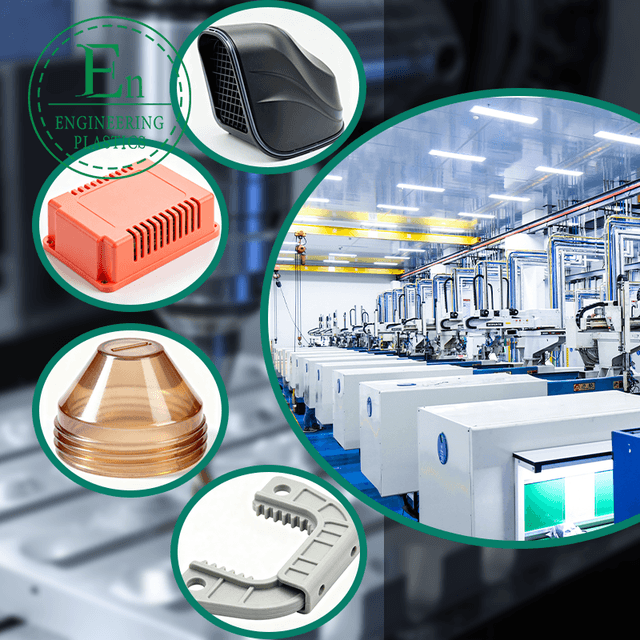

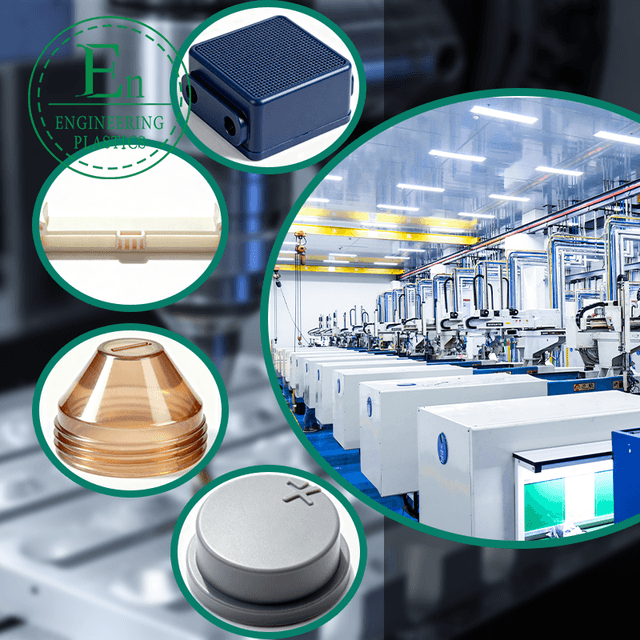

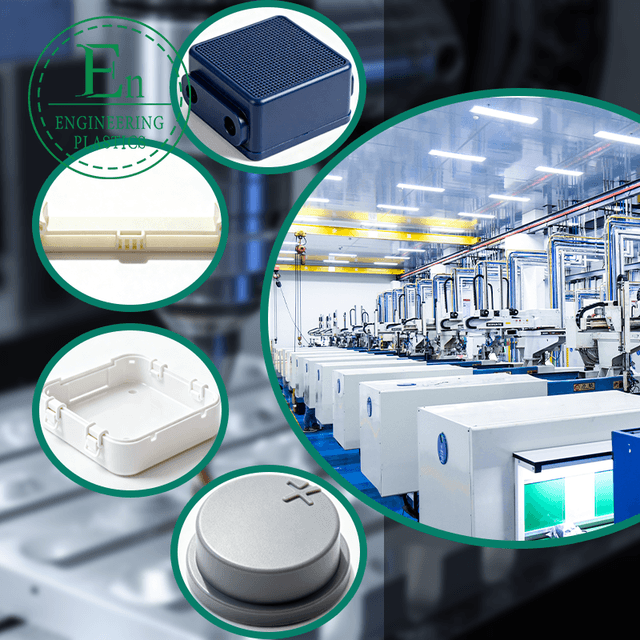

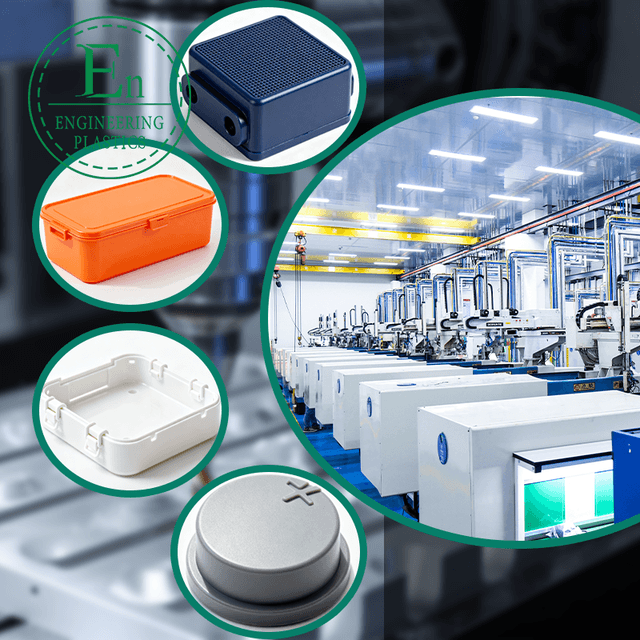

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of precision manufacturing, the bottle mold plastic stands out as a cornerstone for producing high-quality containers across industries. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting advanced bottle mold plastic solutions that combine durability, efficiency, and customization to meet diverse needs. Our expertise ensures that every bottle mold plastic component is engineered for optimal performance, whether for beverage packaging, pharmaceutical vials, or industrial containers. With materials like ABS and Nylon, our bottle mold plastic offerings provide exceptional resistance to wear and tear, making them ideal for high-volume production runs. This focus on quality not only enhances product reliability but also supports sustainable practices by reducing material waste in the molding process.

Delving deeper into our capabilities, silicone mold production is a key process we employ to create intricate and flexible molds that complement our rigid bottle mold plastic designs. Silicone mold production allows for the prototyping and small-batch manufacturing of complex shapes, ensuring that the final bottle mold plastic products achieve unparalleled precision and surface finish. Our senior engineers, with 15-25 years of experience, oversee every stage of silicone mold production, from initial design to final curing, resulting in molds that withstand repeated use without degradation. This method is particularly beneficial for clients requiring custom bottle shapes, as it facilitates rapid iterations and minimizes production downtime. By integrating silicone mold production with our advanced engineering plastics, we deliver components that exceed industry standards, serving sectors like food and beverage where hygiene and exactitude are paramount.

Complementing these processes are our meticulously designed plastic mold components, which form the backbone of any effective molding system. Plastic mold components such as cores, cavities, and ejector pins are crafted from high-grade materials like PEEK and PTFE to ensure longevity and precision in bottle mold plastic applications. At Guangdong Engineering Plastics Industries Group Co., Ltd., we export these plastic mold components to global markets including the USA, UK, Canada, and Germany, earning acclaim for their robustness and compatibility with automated machinery. For instance, our plastic mold components are engineered to handle high pressures and temperatures, preventing defects in the final molded bottles and reducing maintenance costs for our international clients. This comprehensive approach to plastic mold components not only streamlines manufacturing but also allows for personalized solutions tailored to specific production environments.

Our commitment to innovation extends beyond individual elements like bottle mold plastic and plastic mold components; it's about creating an ecosystem of reliable products that drive efficiency. In our state-of-the-art facilities, we produce a wide array of engineering plastic items, including gears and sealing rings, all while prioritizing sustainability through recyclable materials and energy-efficient processes. Clients benefit from our full-spectrum services, encompassing design, research, and development, which ensure that silicone mold production seamlessly integrates with bottle mold plastic workflows. Whether you're a domestic manufacturer or an overseas exporter, partnering with us means accessing top-tier quality that aligns with global regulations and enhances your competitive edge. As we continue to push boundaries in engineering plastics, our bottle mold plastic solutions remain at the forefront, delivering versatility and performance that redefine industry expectations. With over two decades of collective expertise, Guangdong Engineering Plastics Industries Group Co., Ltd. is your trusted partner for all molding needs, fostering long-term success through unwavering dedication to excellence.