We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the competitive world of precision manufacturing, a high-quality cavity mould stands as the cornerstone of efficient production processes. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting cavity moulds that deliver unmatched accuracy and reliability. Our expertise, driven by senior engineers with 15-25 years of hands-on experience, ensures that every cavity mould we produce is tailored to meet the exacting demands of modern industries. Whether you're involved in automotive components or consumer goods, our cavity moulds optimize material flow and minimize defects, leading to superior end products and reduced waste.

Delving deeper into our capabilities, our cavity moulds are integral to advanced bottle mold manufacturing. This process requires meticulous design to handle the complexities of shaping PET or HDPE materials under high pressure and temperature. Our state-of-the-art facility, equipped with cutting-edge injection molding machines, allows us to create cavity moulds that ensure consistent wall thickness and seamless finishes for bottles of all sizes. From pharmaceutical containers to beverage packaging, these moulds enhance production speed while maintaining structural integrity. Clients across the USA, UK, and Germany have relied on our bottle mold manufacturing solutions to scale their operations efficiently, benefiting from our comprehensive design and research services that incorporate materials like Nylon and ABS for durability.

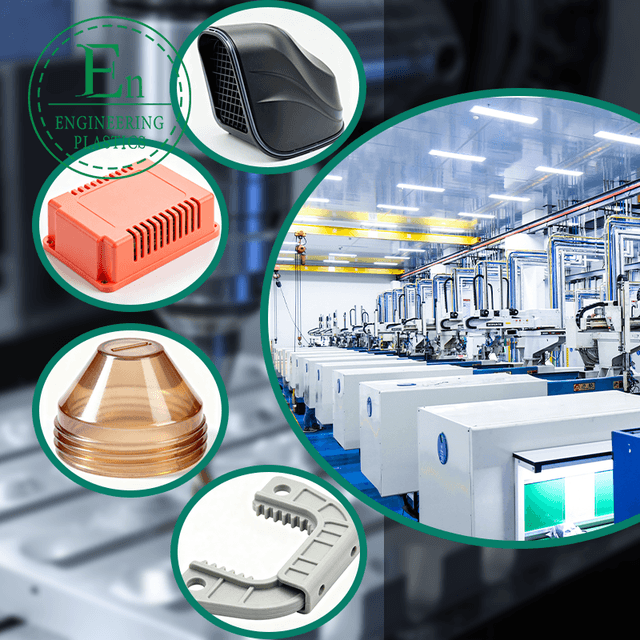

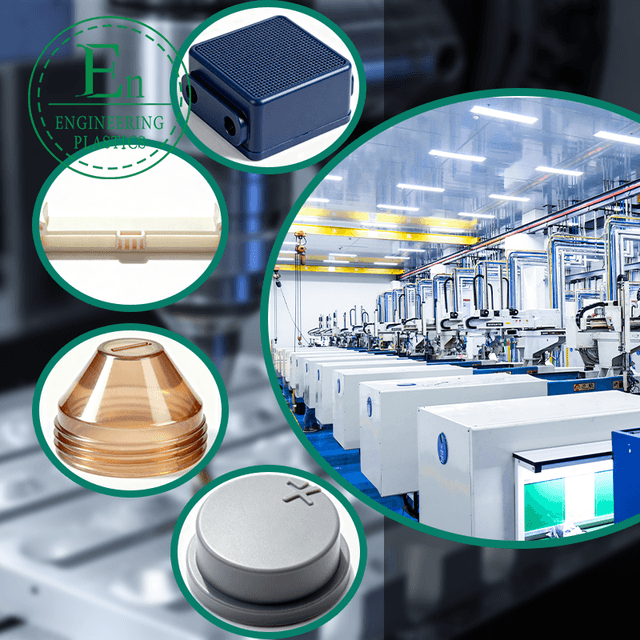

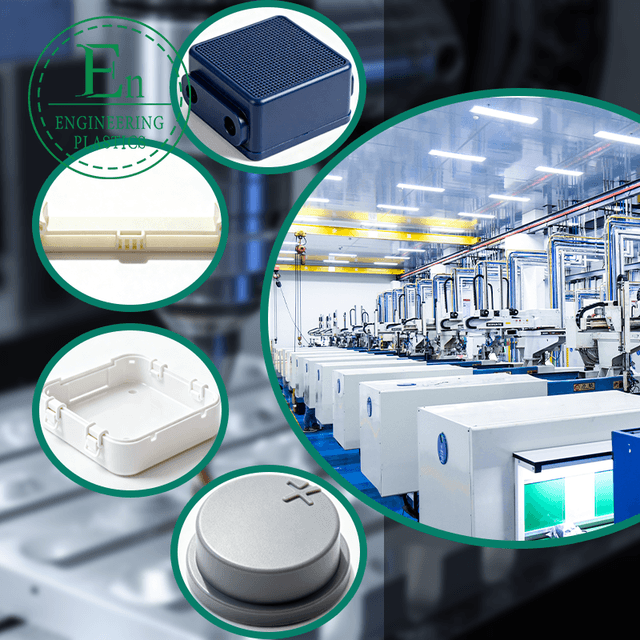

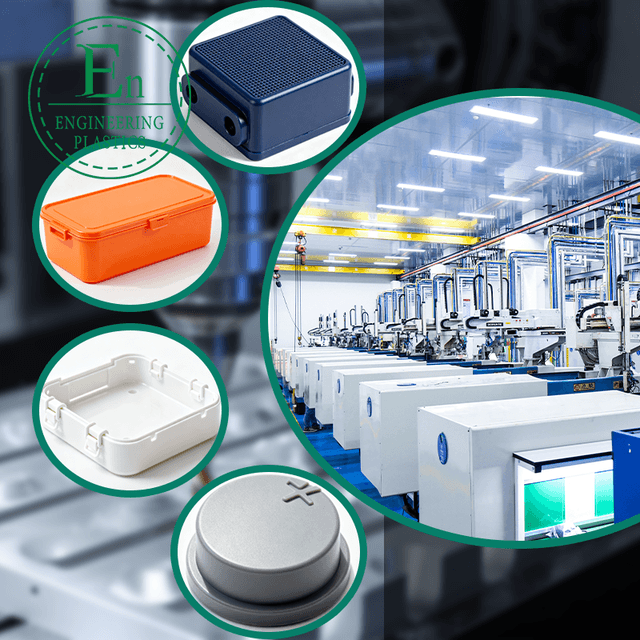

Expanding our portfolio, our cavity moulds also excel in car parts mould applications, where precision is non-negotiable. Automotive manufacturers demand components that withstand extreme conditions, and our moulds are engineered to produce parts like air vent covers, enclosures, and clamps with exceptional tolerance levels. For instance, our sleek black air vent cover, molded using robust engineering plastics such as PEEK and PPS, optimizes airflow while resisting corrosion. Similarly, the robust orange enclosure provides lightweight yet rigid protection for electronic systems in vehicles. Our versatile blue box and durable grey clamp further demonstrate the adaptability of our car parts mould technology, offering customizable options that align with stringent industry standards. With exports to Canada and beyond, we've built a global reputation for innovation in this sector.

What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart is our commitment to personalization and quality. Our team doesn't just manufacture; we collaborate closely with clients to develop cavity moulds that integrate seamlessly into existing workflows. Using advanced materials like PTFE and sealing rings, we ensure longevity and performance. In bottle mold manufacturing, this means faster cycle times and lower energy consumption. For car parts mould, it translates to parts that enhance vehicle safety and efficiency. As we continue to serve diverse markets, our cavity moulds remain at the forefront of engineering plastics innovation, promising reliability and excellence for every project. Explore how our solutions can transform your production line today.