We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

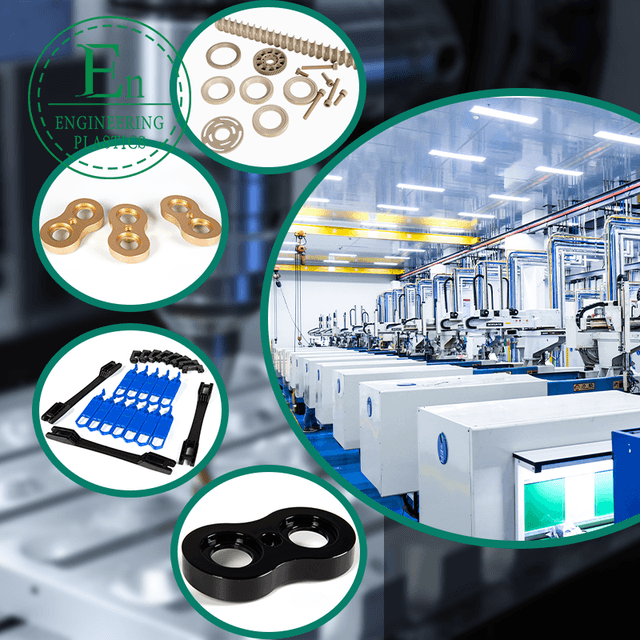

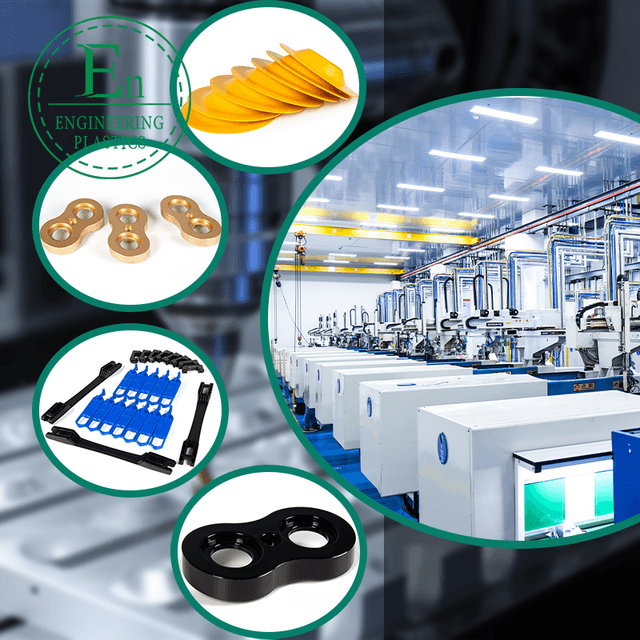

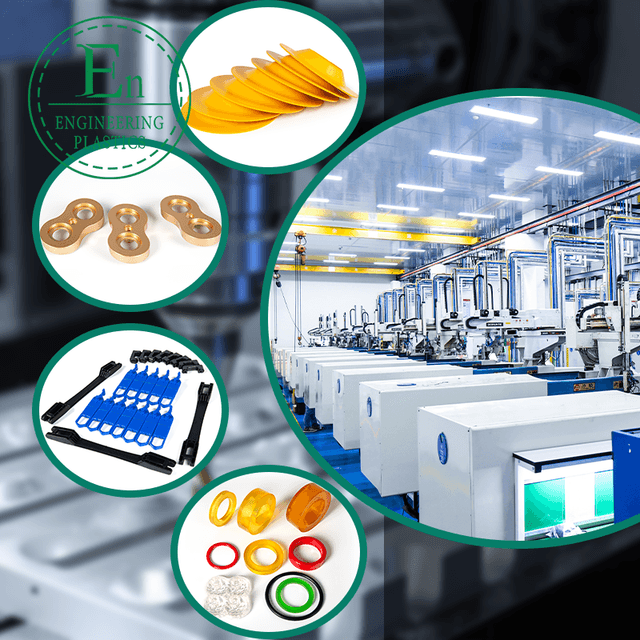

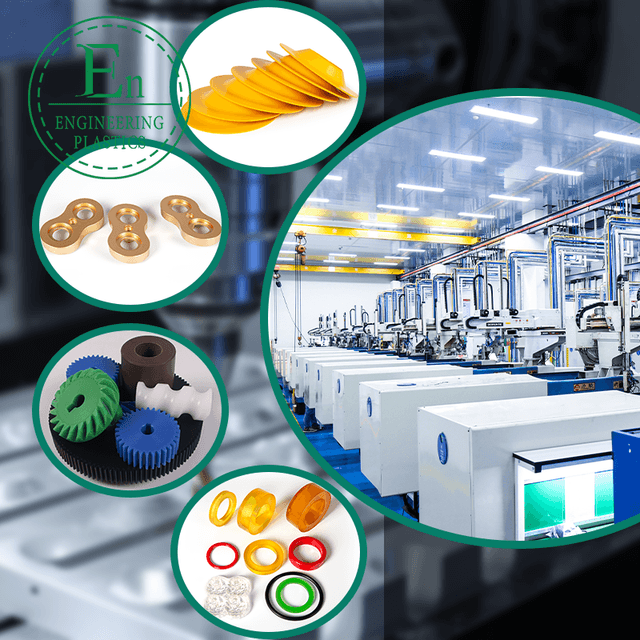

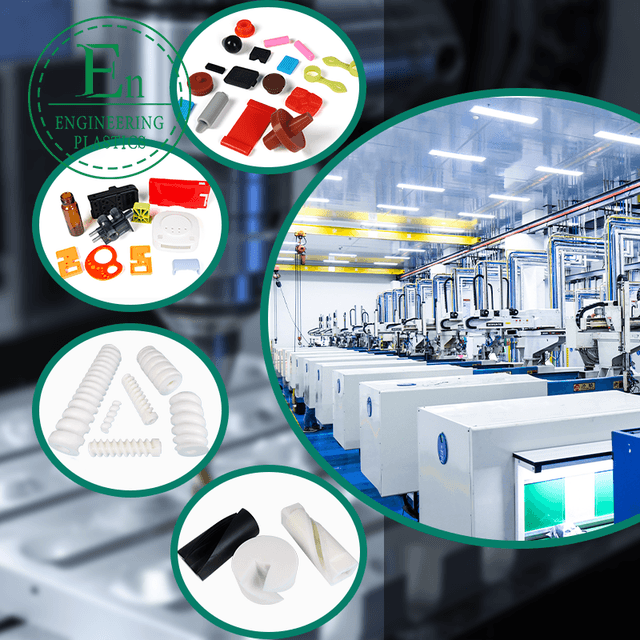

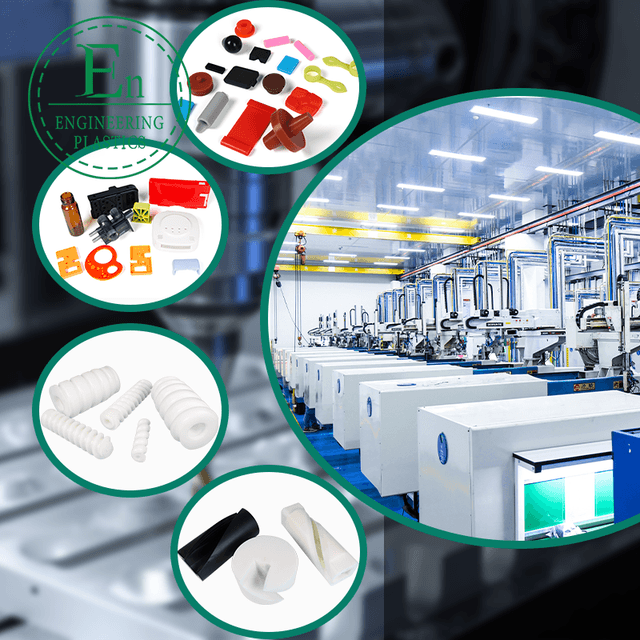

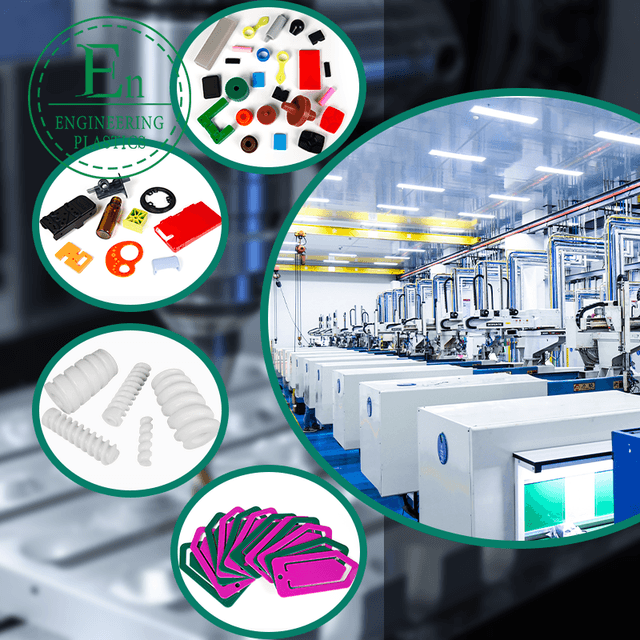

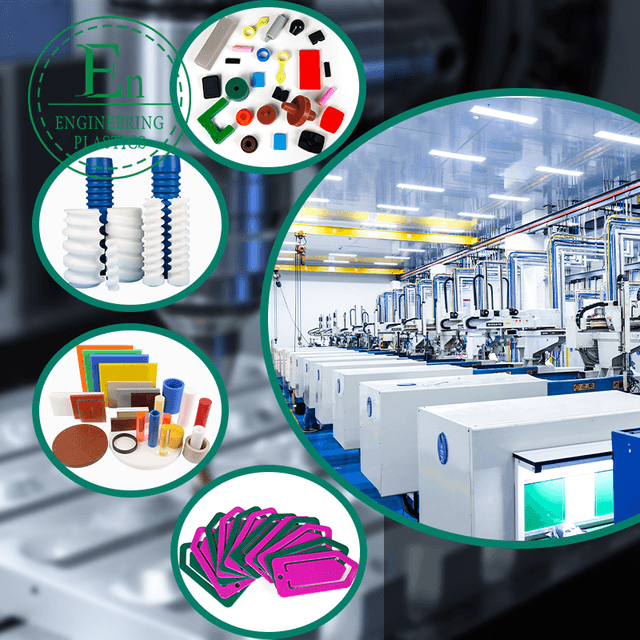

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of precision manufacturing, a 3d printed injection mold represents a revolutionary approach to creating high-quality molds efficiently and cost-effectively. At Guangdong Engineering Plastics Industries Group Co., Ltd., we harness this innovative technology to produce superior mold models and plastic jar molds tailored for diverse industrial needs. Our senior engineers, with 15-25 years of expertise, leverage advanced 3D printing techniques to design and develop molds that ensure precision, durability, and rapid prototyping. This method not only reduces production time but also minimizes material waste, making it ideal for engineering plastics applications where accuracy is paramount.

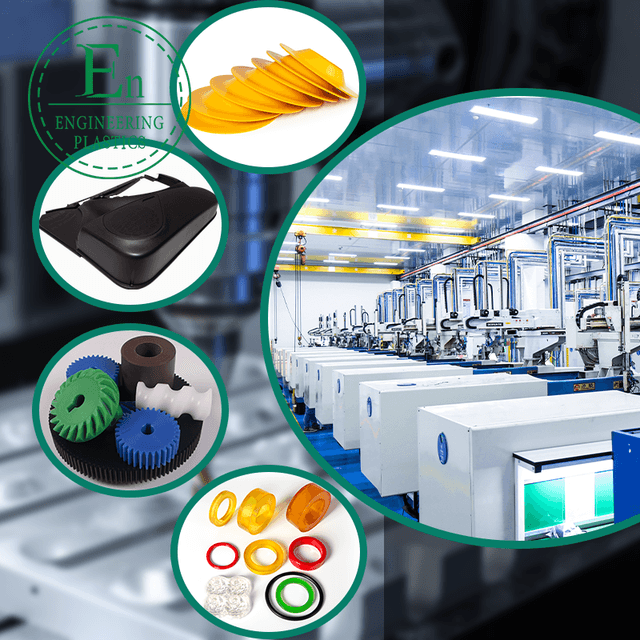

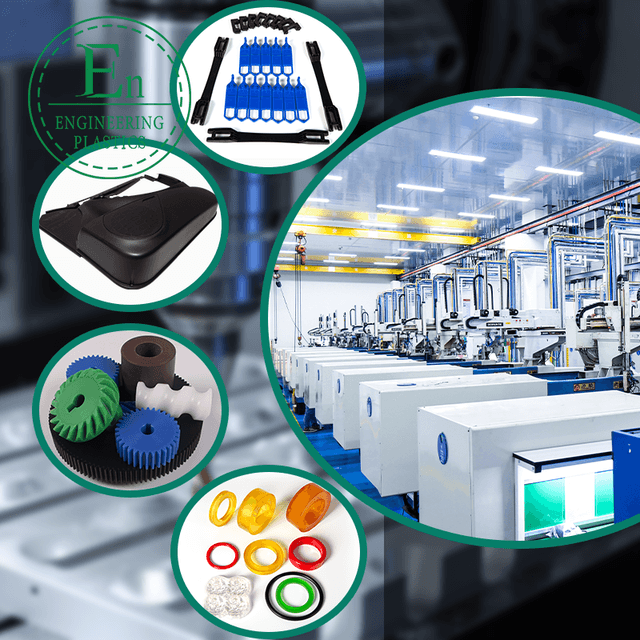

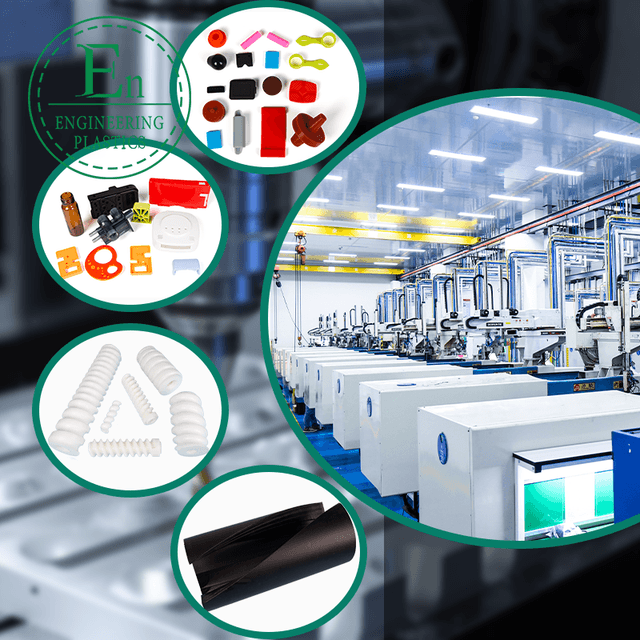

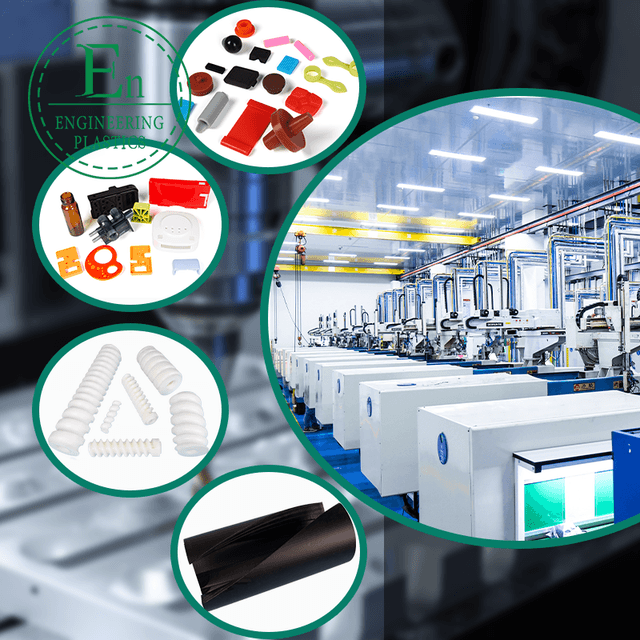

Our 3d printed injection mold process begins with detailed digital modeling, allowing us to create intricate mold models that capture every nuance required for high-performance components. Whether it's for robust plastic gears that reduce friction in mechanical systems or custom connectors providing structural integrity, our molds deliver exceptional results. We specialize in materials like PEEK, PPS, Nylon, ABS, and PTFE, ensuring that each mold model withstands the rigors of injection molding while maintaining tight tolerances. For instance, our plastic jar molds are engineered for seamless production of vibrant seals, washers, and uniquely shaped components, available in various sizes and colors to meet specific client specifications. This versatility positions our 3d printed injection molds as a cornerstone for industries seeking reliable, innovative solutions.

What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart is our commitment to comprehensive research and development, backed by a team of seasoned professionals who offer personalized customization. We export our products to the USA, UK, Canada, Germany, and beyond, building a strong global reputation through consistent quality and cutting-edge production techniques. Our 3d printed injection mold technology integrates seamlessly with our sophisticated injection molding setups, guaranteeing consistency in every piece produced. Clients benefit from mold models that not only accelerate time-to-market but also enhance the longevity of end products like pulleys, sealing rings, and bearings. By focusing on plastic jar molds for packaging and industrial applications, we address demanding requirements with innovative reliability.

Exploring further, the advantages of our 3d printed injection mold extend to sustainability and cost-efficiency. Traditional molding methods often involve lengthy lead times and high tooling costs, but our approach allows for quick iterations and on-demand production of mold models. This is particularly valuable for prototyping plastic jar molds used in the creation of durable containers or specialized components. Our engineering plastics line, including those produced via these molds, showcases the durability of advanced materials in real-world scenarios, from automotive to aerospace applications. With a focus on reducing wear and ensuring tight seals, our molds empower manufacturers to achieve superior performance without compromise.

In summary, Guangdong Engineering Plastics Industries Group Co., Ltd. stands at the forefront of manufacturing excellence with our 3d printed injection mold solutions. By incorporating related expertise in mold models and plastic jar molds, we deliver products that align with modern industry's evolving needs. Our global clientele trusts us for the precision, innovation, and reliability that define every project, proving that advanced technology combined with human ingenuity can transform manufacturing possibilities.