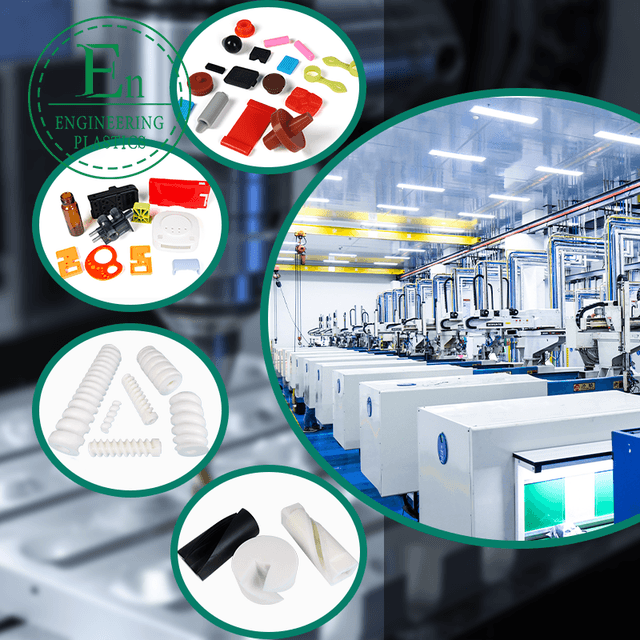

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

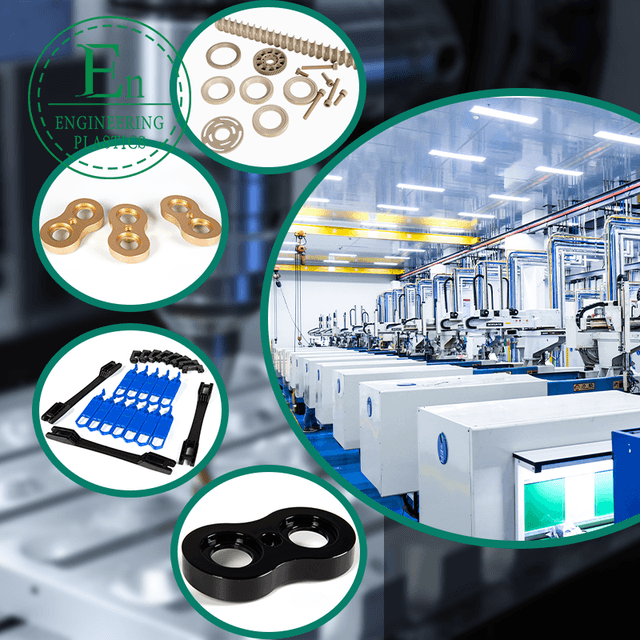

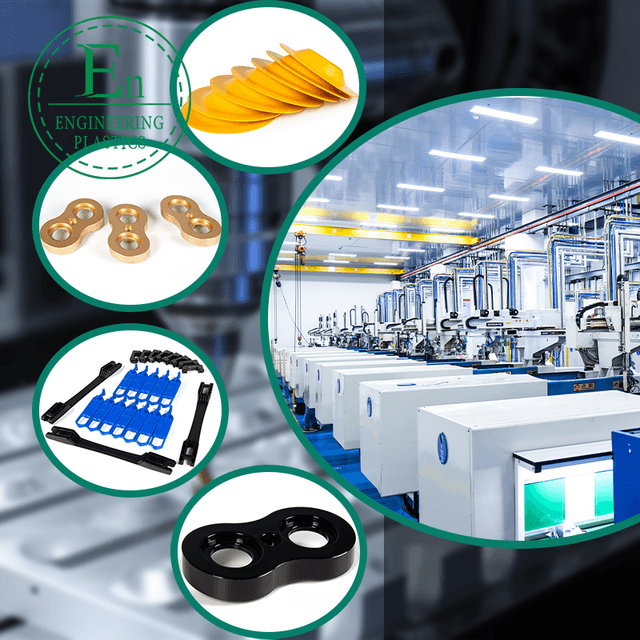

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

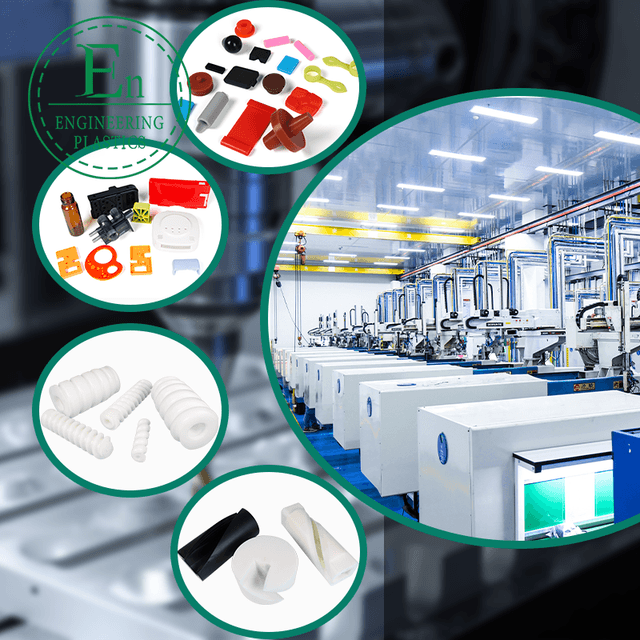

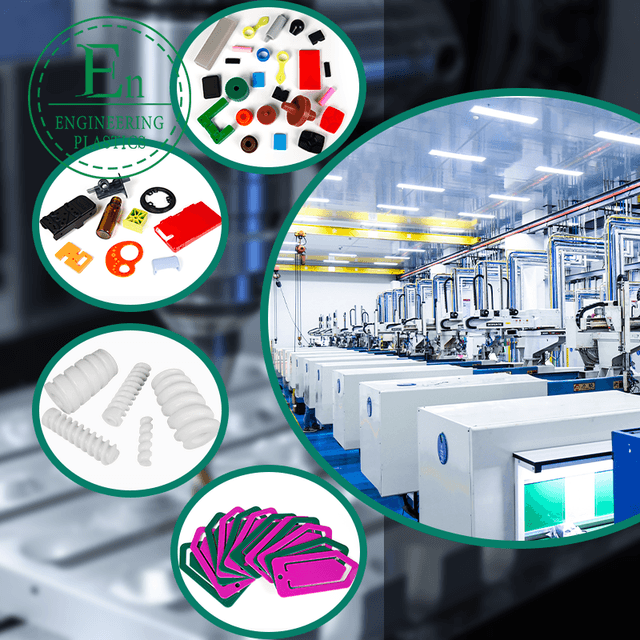

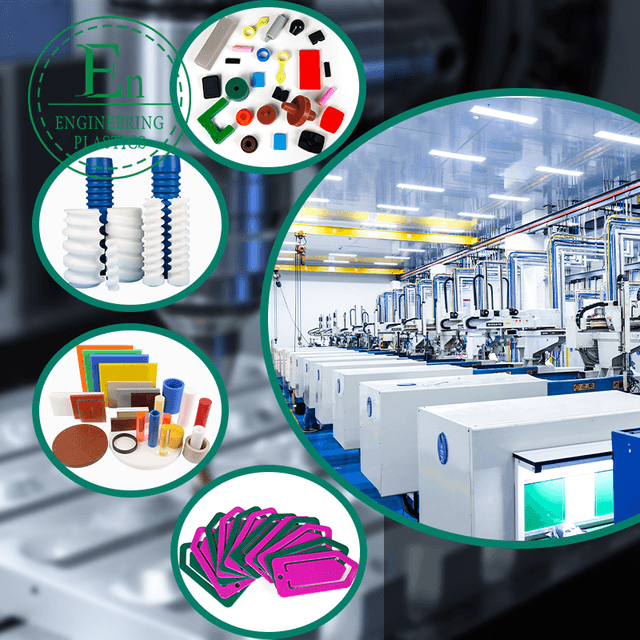

In the world of modern engineering, precision is not just a goal; it is the absolute standard. For industries ranging from automotive to aerospace, the integrity of every single component dictates the performance and safety of the final assembly. At Guangdong Engineering Plastics Industries Group Co., Ltd., we masterfully blend innovation with expertise to deliver state-of-the-art engineering plastic components. By utilizing advanced manufacturing techniques, such as those refined for injection mold silicone, we achieve a level of detail and consistency that sets new industry benchmarks and brings our clients' most demanding designs to life with flawless accuracy.

Our process is a testament to meticulous planning and engineering prowess. The journey of each component from a raw concept to a tangible, functional part is guided by the vast experience of our senior engineers, who possess 15 to 25 years of specialized knowledge. This process begins with an incredibly detailed injection mold diagram, which serves as the foundational blueprint for production. This document is more than a simple drawing; it is a comprehensive plan that outlines every slot, recess, and precision hole, ensuring that the final product integrates seamlessly with existing systems. This attention to detail in the initial injection mould diagram phase is what guarantees the efficiency, reliability, and ease of installation of our components.

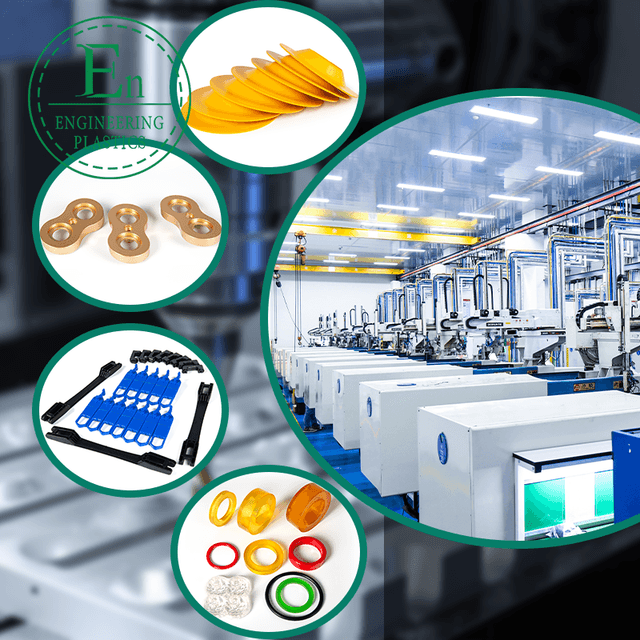

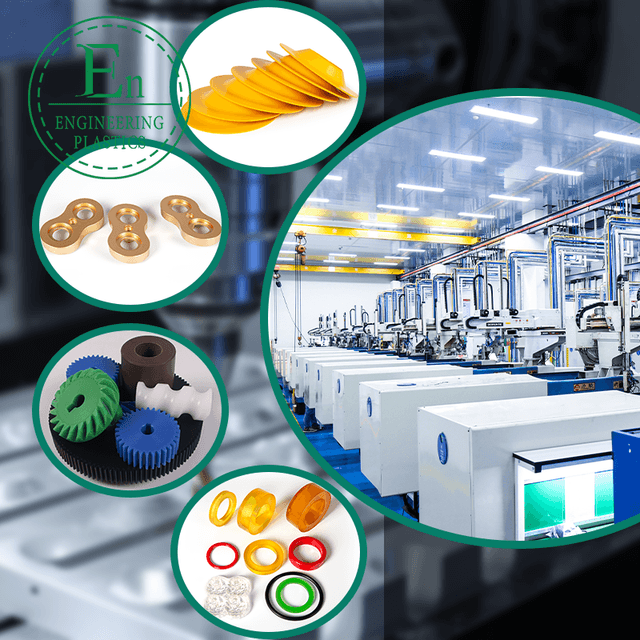

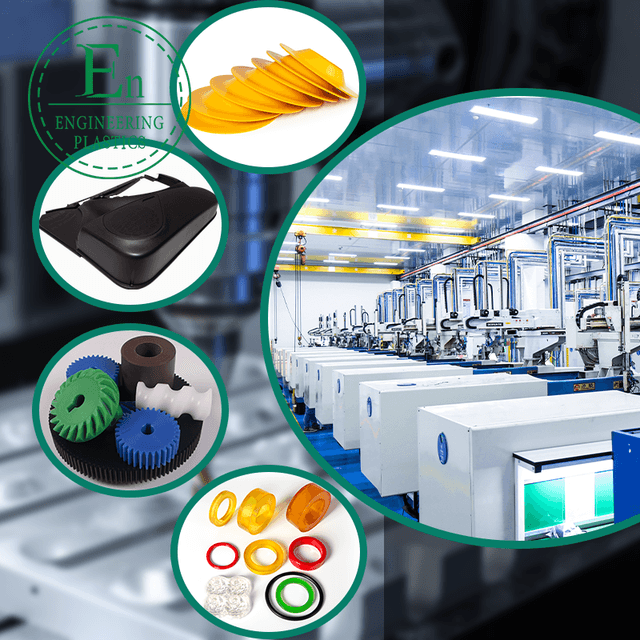

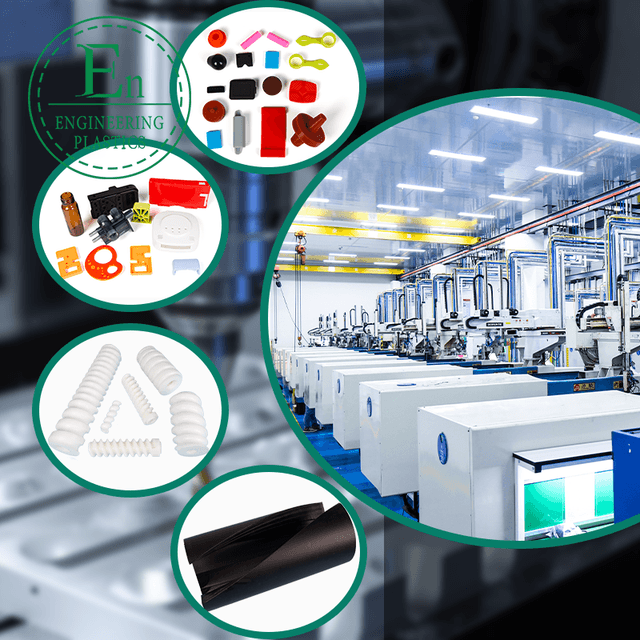

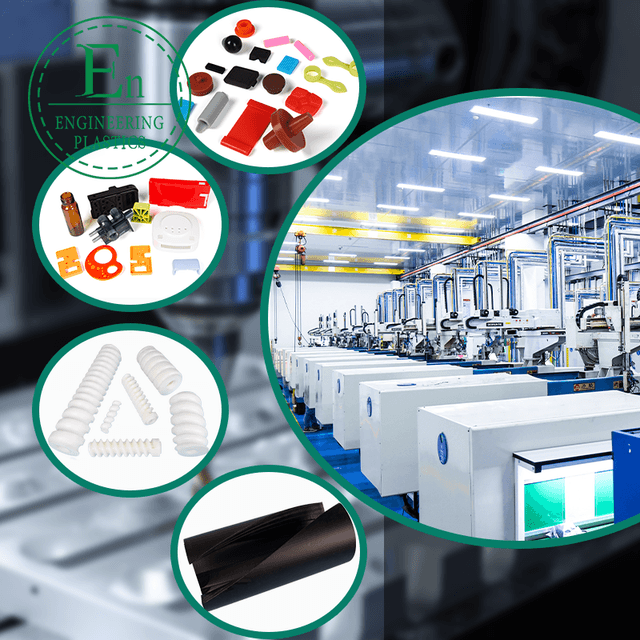

Of course, a flawless design must be executed with superior materials. We manufacture our components from a curated selection of premium, high-performance engineering plastics, including industry-leading materials like PEEK, PPS, Nylon, ABS, and PTFE. These materials are chosen for their outstanding mechanical properties, offering exceptional tensile strength, remarkable resistance to wear and tear, and superior thermal and chemical stability. This resilience ensures our products deliver long-lasting durability and peak performance even in the harshest operational environments. Our components, available in vibrant orange, subtle pastel yellow, and classic crisp white, are not only robust but also designed for high visibility and easy identification within complex machinery.

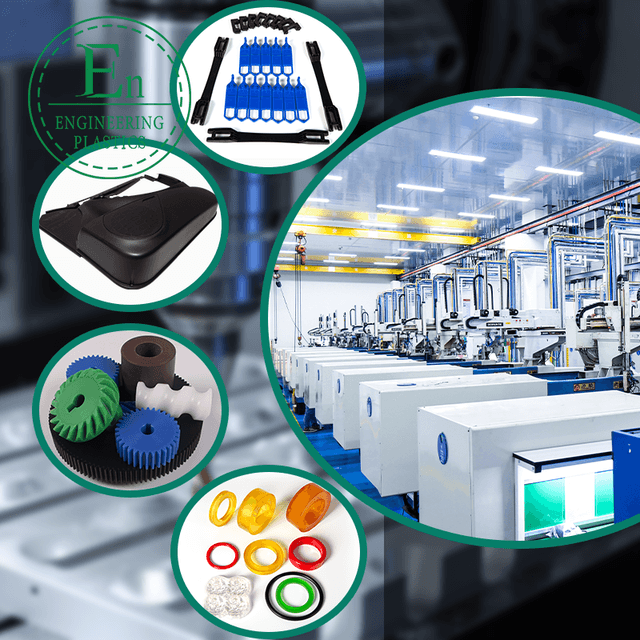

We recognize that a one-size-fits-all approach is insufficient for the unique challenges our clients face. That is why our core strength lies in personalized customization. Our comprehensive design, research, and development capabilities allow us to create a wide array of bespoke engineering plastic products, from complex gears and pulleys to essential sealing rings and bearings. We work closely with our clients to transform their specific requirements into functional, precision-engineered solutions. This commitment to tailored service has allowed us to build a strong global reputation, proudly exporting our products to satisfied clients in the USA, UK, Canada, Germany, and beyond.

Choosing Guangdong Engineering Plastics Industries Group Co., Ltd. means investing in a partnership dedicated to excellence. We bring modern engineering brilliance and sustainable innovation directly to your operations. Whether you are developing a new prototype or seeking to upgrade an existing system, our advanced manufacturing processes and cutting-edge materials provide the ultimate choice for precision-engineered components that you can trust. Let our team of seasoned experts provide the versatile, reliable, and high-performance solutions your projects deserve.